Slide holder for liquid-based specimen preparation and staining machine

A dyeing machine and slide clip technology, which is used in the preparation, sampling, and instrumentation of test samples, can solve the problems of material corrosion, dyeing liquid temperature loss, slow heating of air heating, etc., and achieves good elasticity retention ability and reduces energy. Loss, avoid the effect of material corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

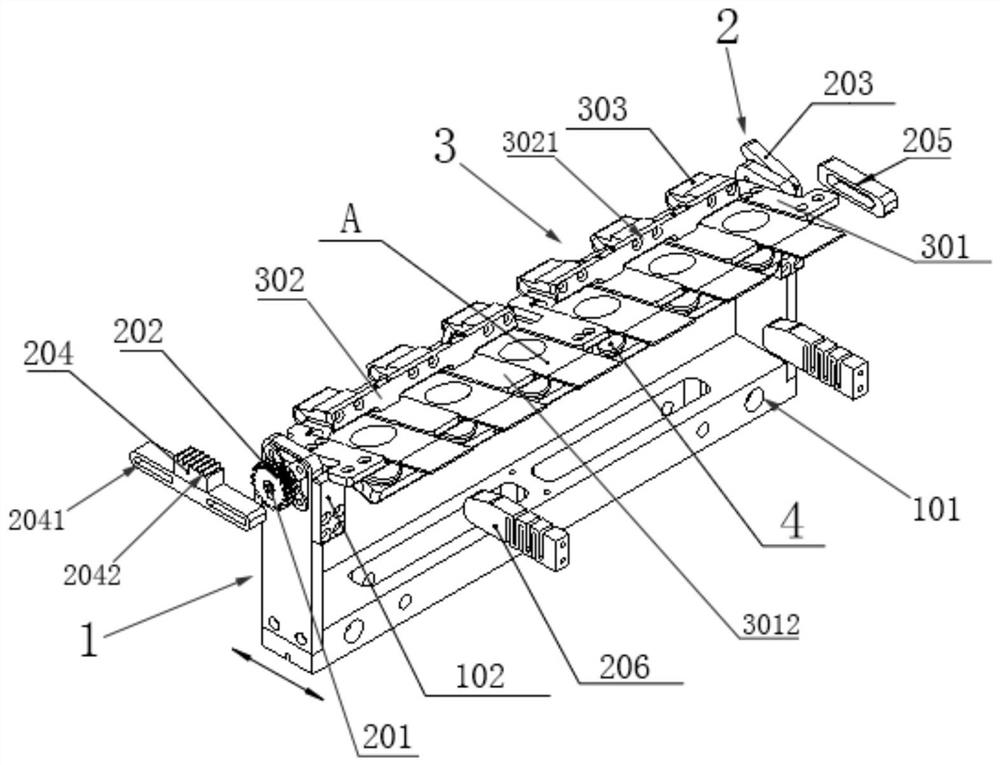

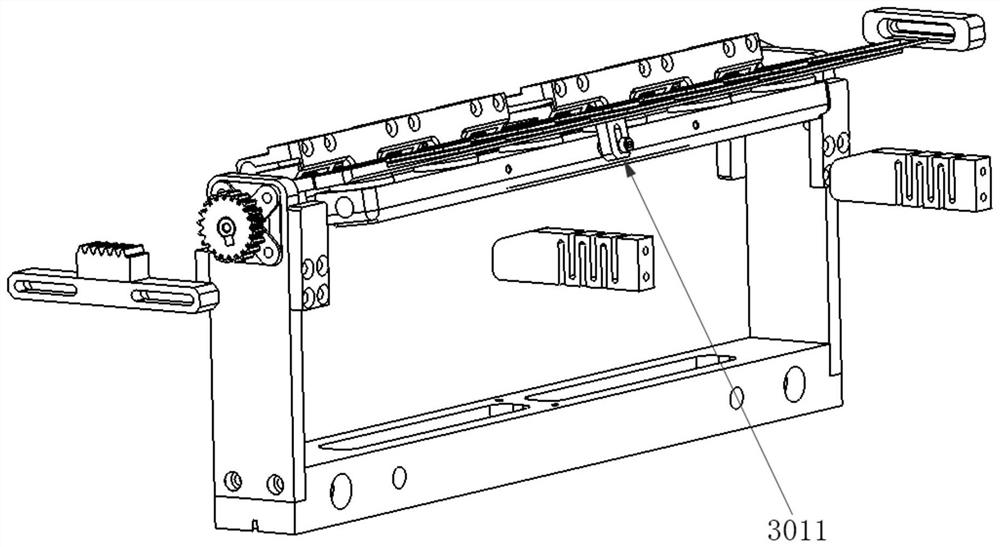

[0050] According to an embodiment of the present invention, the transmission unit 2 includes a central shaft 201 , a gear 202 , and a turning block 203 . The central shaft 201 is installed in the corresponding hole on the upper end of the support frame 1, the gear 202 is installed at one end of the central shaft 201, and the turning block 203 is installed at the other end of the central shaft 201, and is inclined at a certain angle relative to the horizontal plane.

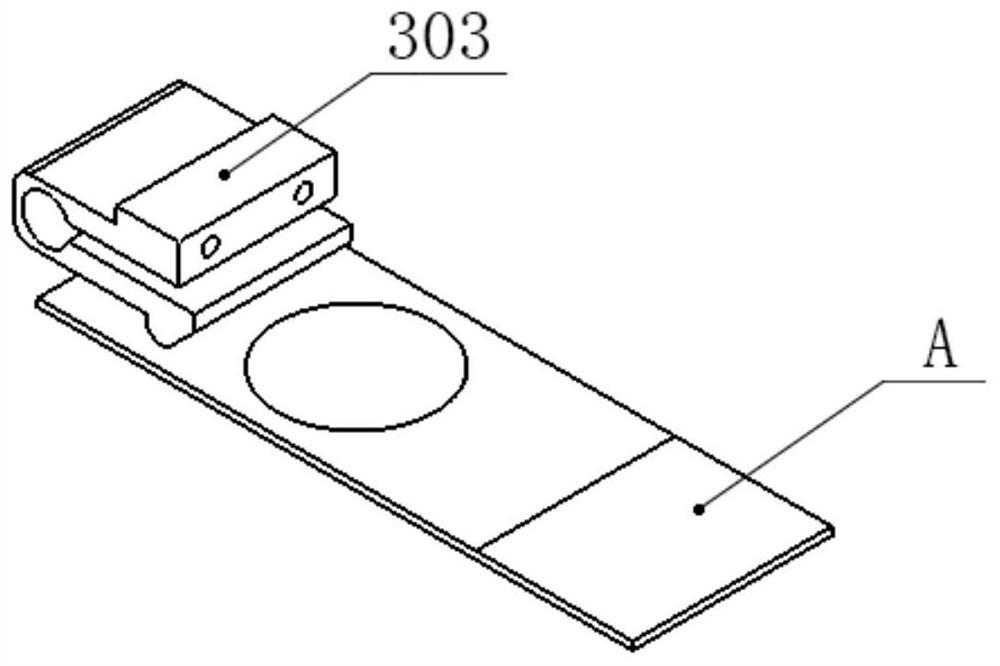

[0051] According to one embodiment of the present invention, the clamping unit 3 includes a bottom plate 301 , a support piece 302 and an elastic member 303 . The bottom plate 301 is flat and fixedly connected to the central axis 201 . Bottom plate 301 is provided with the installation groove (not shown in the figure) of installing glass slide and fixed platform 3011 fixed platform 3012, and installation groove and fixed platform 3011 fixed platform 3012 are arranged axially along central axis 201 alternately, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com