Graphene oxide surface pattern processing system based on femtosecond laser with spatial light shaping

A graphene surface, femtosecond laser technology, applied in the field of femtosecond laser applications, can solve the problems of poor repeatability, unsuitable for large-scale repeated processing, low processing efficiency, etc., to achieve fast processing, fast repeated processing, and improve processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

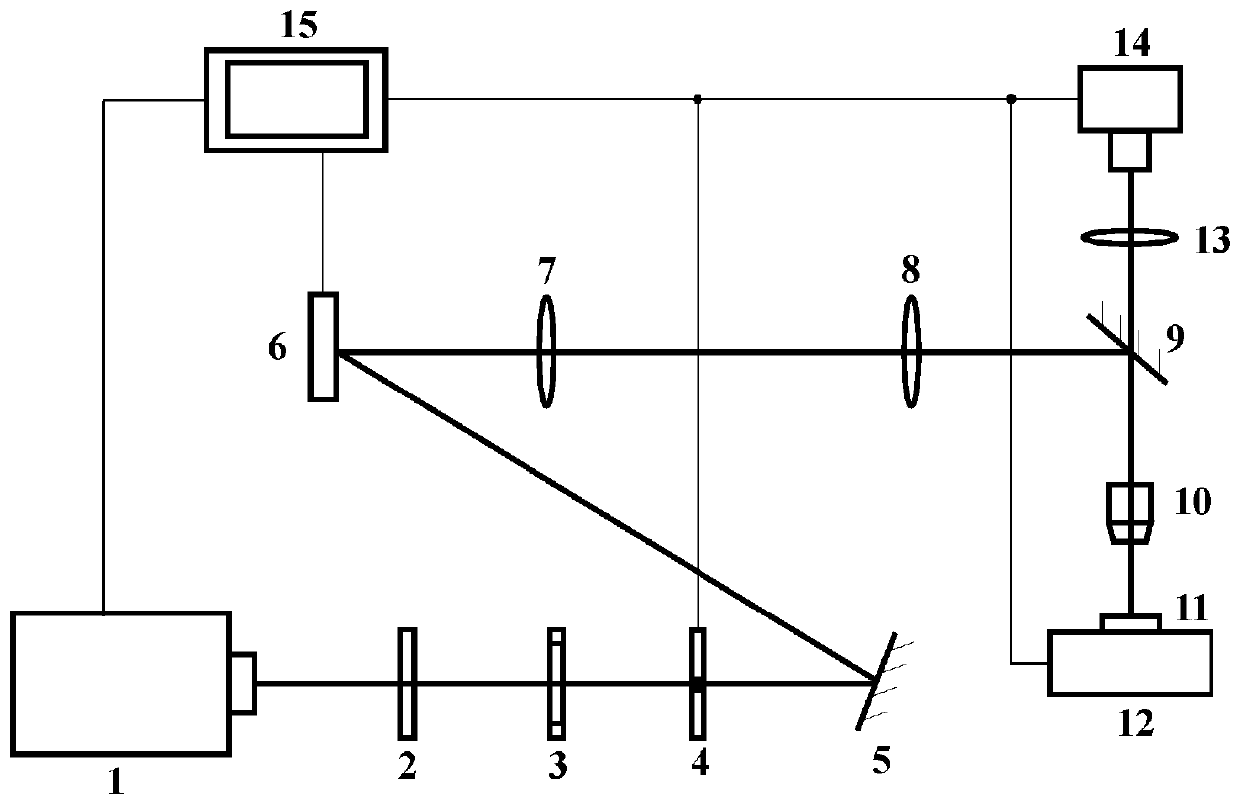

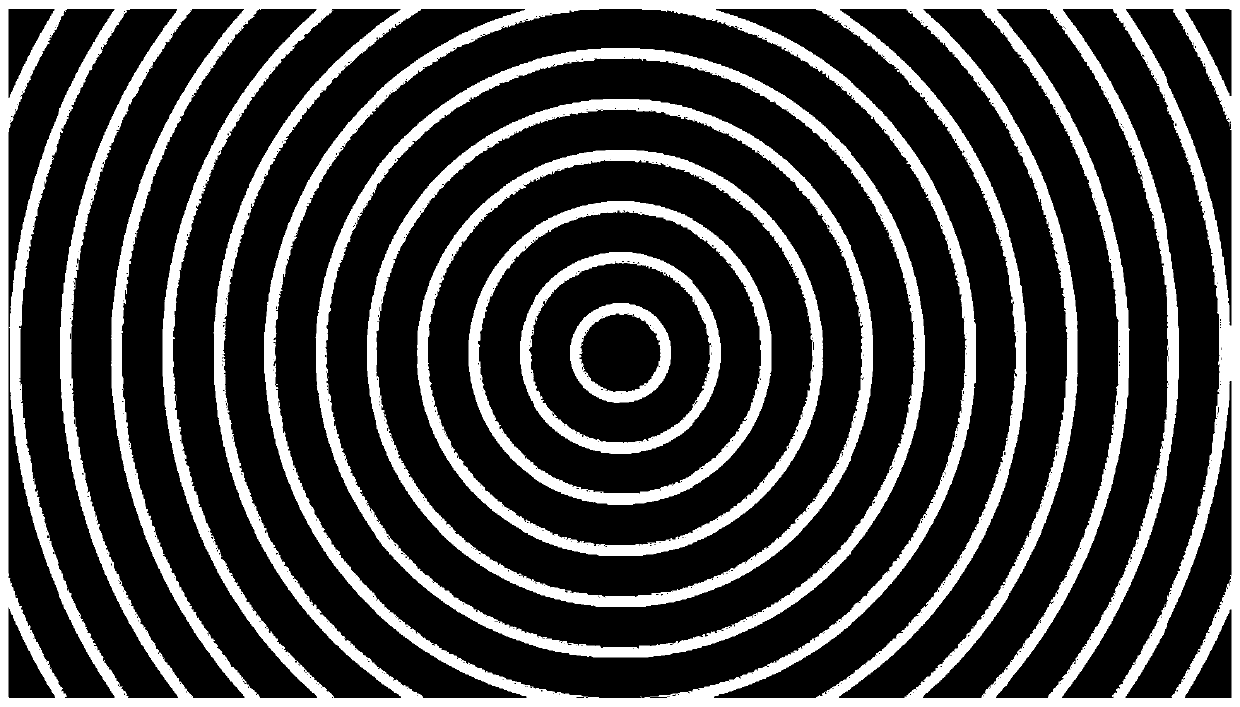

[0025] To process the annular pattern on the surface of GO 11, it is necessary to load an axicon-type phase map on the SLM 6, the phase map is as follows figure 2 shown. Turn on the femtosecond laser 1 to generate femtosecond laser, adjust the spot diameter to 8mm through the diaphragm 2, and adjust the laser power to 2mW through the attenuation sheet 3. Using the control software on the computer 15, the phase map described above is loaded onto the SLM 6. The femtosecond laser reflected from the SLM6 propagates to the focusing objective lens 10 through the optical 4f system composed of the first convex lens 7 and the second convex lens 8, and is focused by the focusing objective lens 10, and the translation stage 12 is controlled to move up and down so that the focus is aligned on the surface of the GO 11 . Use the computer 15 to set the opening time of the electronically controlled shutter 4 to 10ms, open the shutter to process a circular pattern on the surface of the GO 1...

Embodiment 2

[0028] A pattern array in the shape of the letter "T" is processed on the surface of GO 11. First, the iterative Fourier transform method is used to calculate the phase diagram corresponding to the light field of this shape. The calculated phase diagram is as follows: Figure 4 shown. Adjust the laser power to 1.5mW, use calculation 15 to load the calculated phase map onto the SLM 6, focus in the same way as in Example 1, and set the opening time of the electronically controlled shutter 4 to 20ms. By controlling the movement of the translation stage 12 at an interval of 40um and opening the shutter once at each position, the movement of the translation stage enables the laser to process a 6x4 letter "T" pattern array on the surface of the GO 11 .

[0029] It can be seen from Example 2 that the phase map is calculated by using the iterative Fourier transform algorithm and loaded onto the surface of the SLM, which can realize fast and repetitive processing of patterns of arbitra...

Embodiment 3

[0031] Process the pattern in the shape of the letter "THU" on the surface of GO 11. The pattern can be divided into three parts "T", "H" and "U". For each part, the iterative Fourier transform method is used to calculate the corresponding phase map , the calculated phase diagram is as Figure 6 shown. Adjust the laser power to 1.5mW, firstly load the phase map corresponding to the letter "T" pattern onto the SLM6, and the focusing method is the same as that in Embodiment 1. Set the opening time of the electronically controlled shutter 4 to 20ms, open the shutter for processing, and obtain a pattern in the shape of the letter "T", then control the translation stage 12 to translate 50um, and then load the phase map corresponding to the pattern of the letter "H" to the SLM 6 Open the shutter for processing, and finally control the translation stage 12 to continue to translate for 50um, load the phase map corresponding to the letter "U" pattern to the SLM 6, open the shutter for p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com