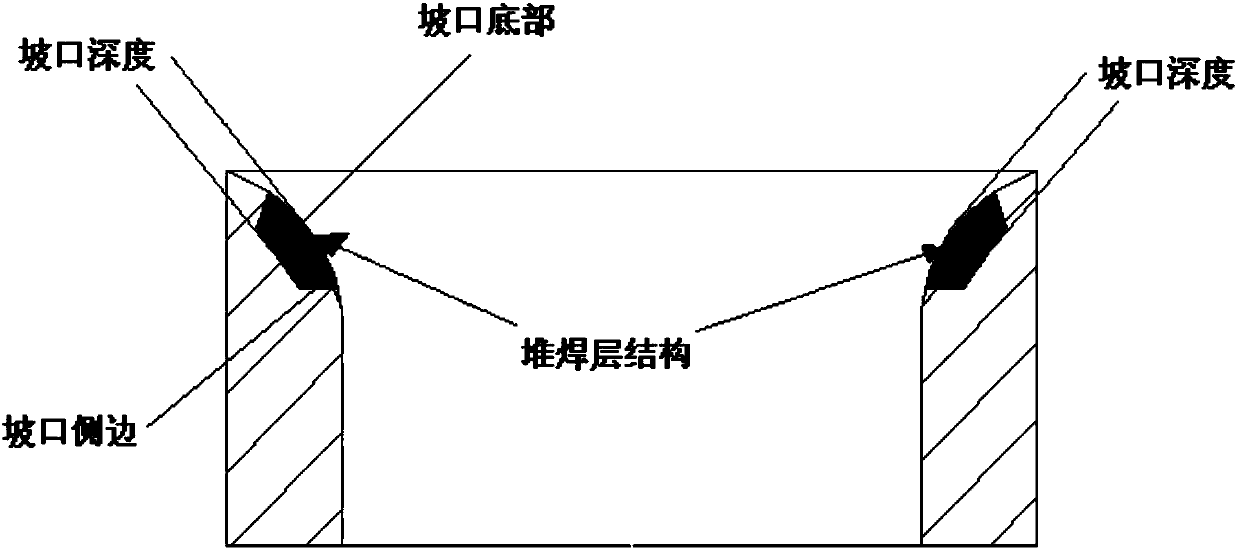

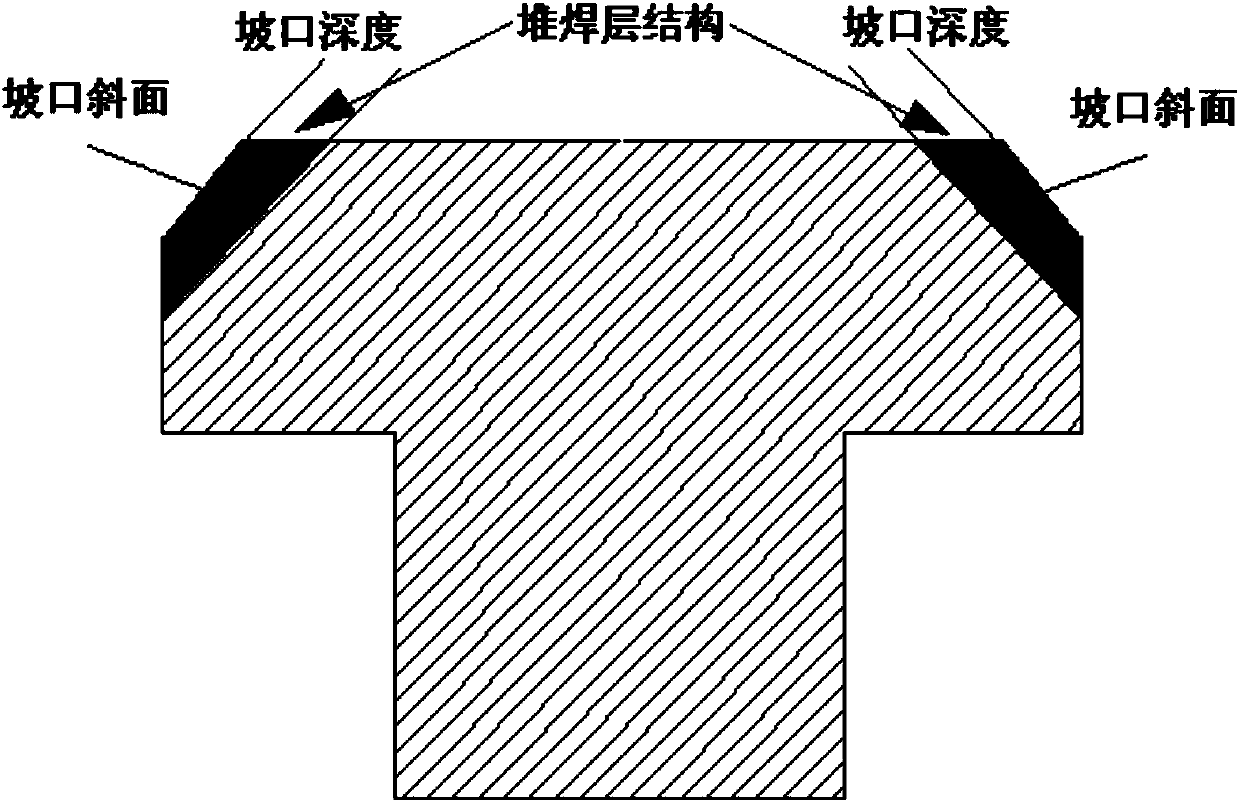

Sealing surfacing layer in steam turbine valve and structure thereof

A technology of steam turbine and surfacing layer, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve problems such as cracking, and achieve the effects of strong field operability, convenient workshop production, and good weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The surfacing materials provided in the present invention are selected, and the corresponding contents of each element component in the surfacing materials are shown in Table 1. The selected surfacing material was surfacing on the 9-12% CrMoV steel base metal to form the surfacing layer sample 1# to test its manufacturability and weldability. The anti-wear, anti-corrosion, and oxidation performance tests were carried out on the surfacing layer sample 1#, and the corresponding index data were obtained. Comparing the performance index data of the surfacing layer sample 1# with the existing Stellite No. 21 material surfacing welding to form the performance index data of the surfacing layer sample 1*, it can be seen that the surfacing material in the present invention can effectively replace the existing surfacing material. The specific performance index data are shown in Table 2.

[0043] Table 1

[0044] element name Chemical Composition (Wt%) C ≤0.10 ...

Embodiment 2

[0049] According to the product requirements, the welding process evaluation of the surfacing layer material prepared in the present invention is carried out according to the ASMEⅨ standard. According to the standard requirements, the test plate is first welded, the welding material is the surfacing layer sample 1# in Example 1, and the base material is 9-12% CrMoV steel. Preheat to 150-250°C before welding, and perform post-weld heat treatment at 650-700°C after welding. Appearance and penetration non-destructive inspections were carried out on the test panels, and the inspection results were qualified. The destructive inspection of the test plate includes macroscopic inspection, hardness inspection and chemical composition inspection. No defects such as lack of fusion and pores were found in the macroscopic inspection, and the fusion with the base metal was good. The hardness and chemical composition were tested at the thickness of the surfacing layer, that is, 3-10mm. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com