Method for constructing blade net nanostructure on surface of aluminum alloy

A technology of aluminum alloy surface and nanostructure, applied in metal material coating process, coating, etc., to achieve good biological safety and biocompatibility, good bactericidal performance, and simple and convenient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

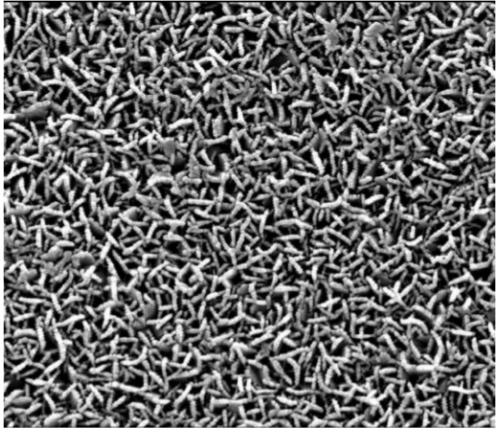

Embodiment 1

[0033] A method for constructing a blade net nanostructure on the surface of an aluminum alloy, taking the aluminum alloy 5A06 as an example, comprising the following steps:

[0034] Step 1: Cut the aluminum alloy plate into a size of 5cm×5cm, polish it with 1200-grit sandpaper, then immerse it in deionized water and acetone for 10 minutes for ultrasonic cleaning, and finally dry it at 50°C for 30 minutes;

[0035] Step 2: Add 50mL of HMTA aqueous solution (50mmol / L) to 50mL of zinc nitrate aqueous solution with a concentration of 50mmol / L, mix well and pour into the reaction kettle;

[0036] Step 3: Add Na in the mixed solution obtained in step 2 2 CO 3 and NH 3 Deionized aqueous solution, Na in the final solution 2 CO 3 and NH 3 The concentration is 0.5mmol·L -1 ;

[0037] Step 4: Preheat the reaction kettle in an oven at 50°C for 15 minutes, put the aluminum alloy plate prepared in step 1 in the reaction kettle, and conduct a hydrothermal reaction at 50°C for 4 hours...

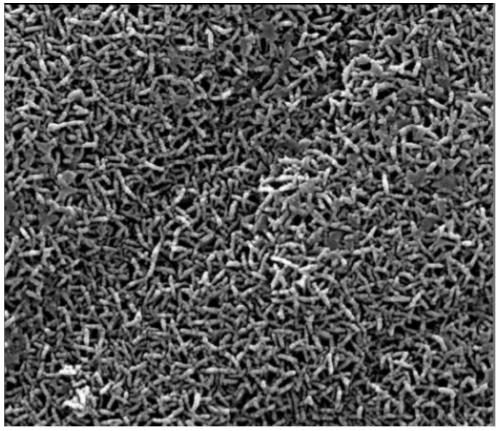

Embodiment 2

[0041] A method for constructing a blade net nanostructure on the surface of an aluminum alloy, taking the aluminum alloy 5A06 as an example, comprising the following steps:

[0042] Step 1: Cut the aluminum alloy plate into a size of 5cm×5cm, polish it with 1200-grit sandpaper, then immerse it in deionized water and acetone for 10 minutes for ultrasonic cleaning, and finally dry it at 50°C for 30 minutes;

[0043] Step 2: Add 100mL of HMTA aqueous solution (70mmol / L) to 100mL of zinc nitrate aqueous solution with a concentration of 70mmol / L, mix well and pour into the reaction kettle;

[0044] Step 3: Add Na in the mixed solution obtained in step 2 2 CO 3 and NH 3 Deionized aqueous solution, Na in the final solution 2 CO 3 and NH 3 The concentration is 1mmol·L -1 ;

[0045] Step 4: Preheat the reaction kettle in an oven at 70°C for 15 minutes, put the aluminum alloy plate prepared in step 1 in the reaction kettle, and conduct a hydrothermal reaction at 70°C for 4 hours; ...

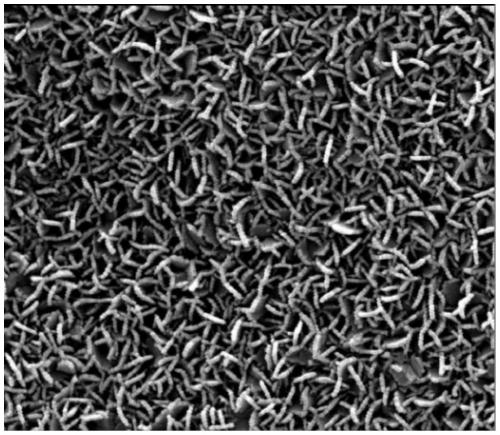

Embodiment 3

[0049] A method for constructing a blade net nanostructure on the surface of an aluminum alloy, taking the aluminum alloy 5A06 as an example, comprising the following steps:

[0050] Step 1: Cut the aluminum alloy plate into a size of 5cm×5cm, polish it with 1200-grit sandpaper, then immerse it in deionized water and acetone for 10 minutes for ultrasonic cleaning, and finally dry it at 50°C for 30 minutes;

[0051] Step 2: Add 100 mL of HMTA aqueous solution (200 mmol / L) to 100 mL of zinc nitrate aqueous solution with a concentration of 200 mmol / L, mix well and pour into the reaction kettle;

[0052] Step 3: Add Na in the mixed solution obtained in step 2 2 CO 3 and NH 3 Deionized aqueous solution, Na in the final solution 2 CO 3 and NH 3 The concentration is 2mmol·L -1 ;

[0053] Step 4: Preheat the reaction kettle in an oven at 80°C for 15 minutes, put the aluminum alloy plate prepared in step 1 in the reaction kettle, and conduct a hydrothermal reaction at 80°C for 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com