Method for predicting tension-compression fatigue hysteresis loop of metal matrix composite material

A technology of titanium-based composite materials and composite materials, which is applied in the field of prediction of tension-compression fatigue hysteresis loops of metal-based composite materials, and can solve problems such as time-consuming, high cost, and labor consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

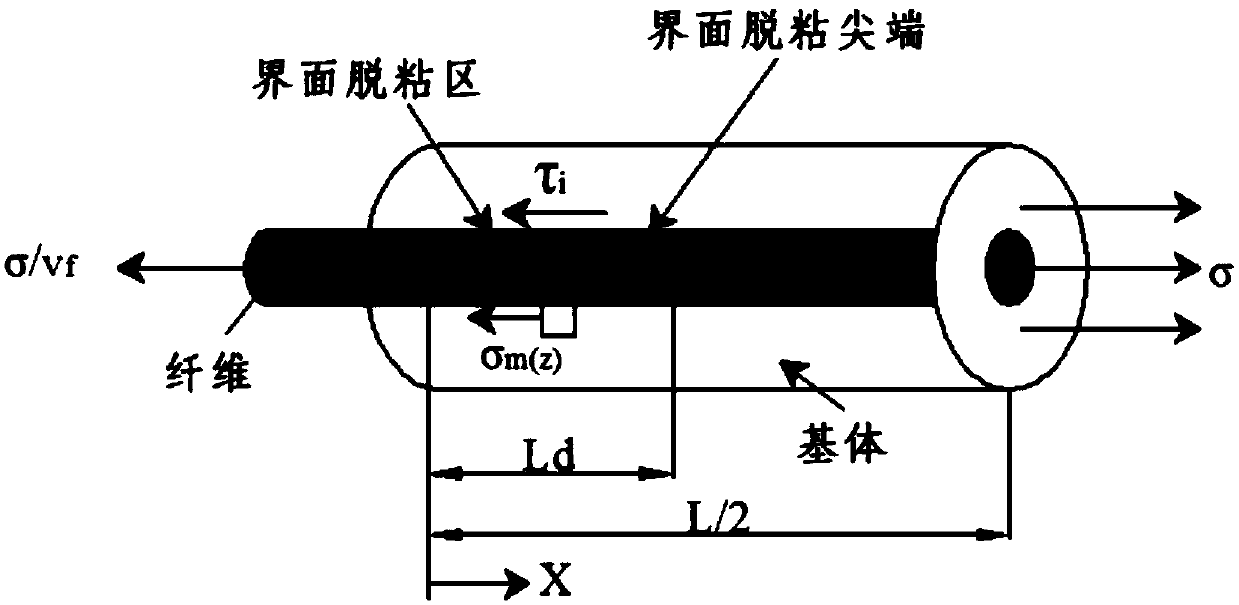

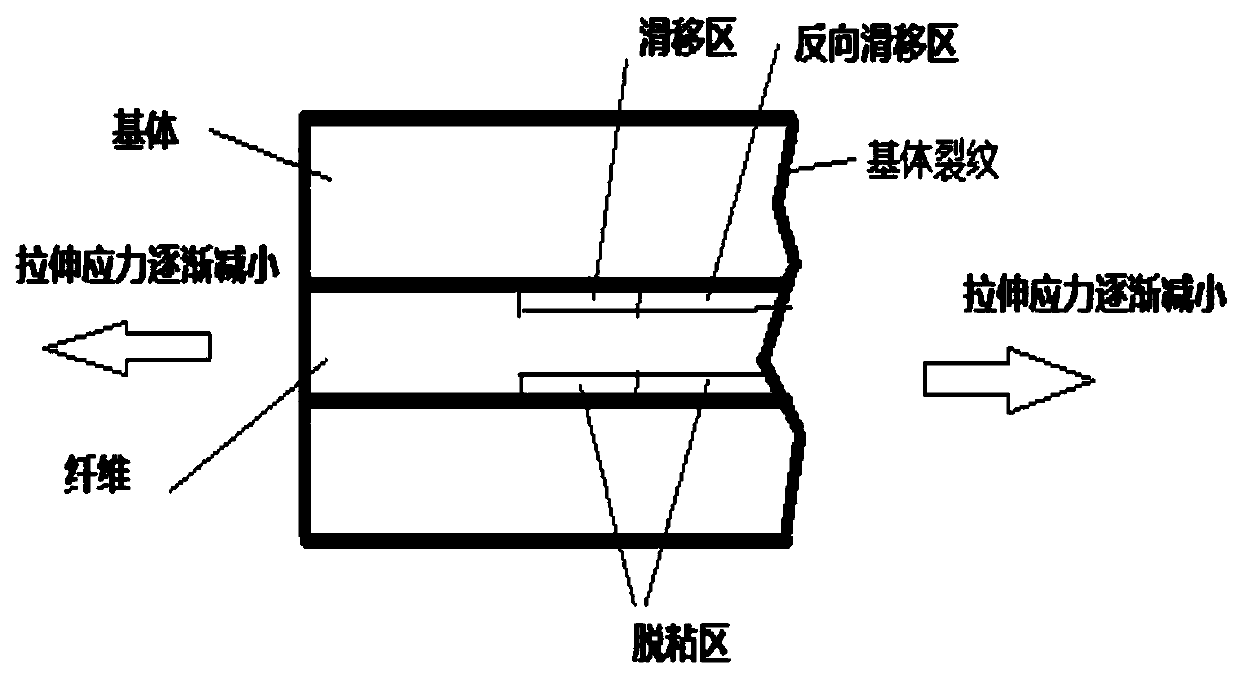

Method used

Image

Examples

Embodiment

[0196] Table 2 Composite material parameters

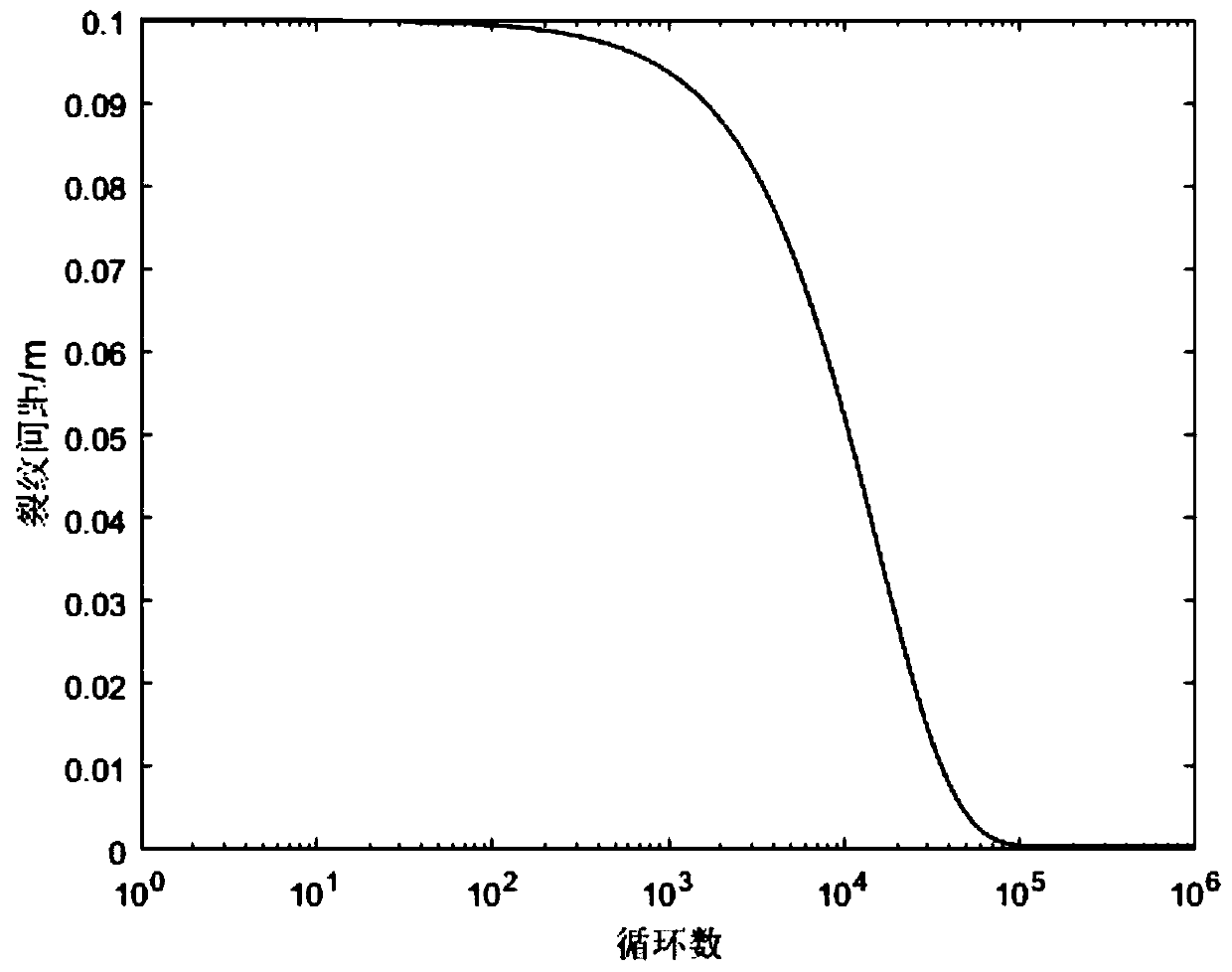

[0197]

[0198] Given the number of cycles N = 1, 88500, 98500, and the temperature difference ΔT = -279, the matrix crack spacing at this time can be obtained by formula (34), and the current cycle number can be obtained by formula (35). The shear stress of the sliding interface, the reference strength of the fiber under the number of cycles at this time can be obtained by formula (42). According to formula (41), the fiber failure probability under the number of cycles at this time can be obtained by using the loop iteration method. At this point, the following material parameters can be obtained:

[0199] Effective fiber volume fraction:

[0200] V f =V f0 (1-P(T)) (43)

[0201] Composite elastic modulus:

[0202] E. 1 =E m V m +E f V f (44)

[0203] Composite thermal expansion coefficient:

[0204]

[0205] Composite matrix shear modulus:

[0206]

[0207] According to formula (17) (18) (19) (21) (23), t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com