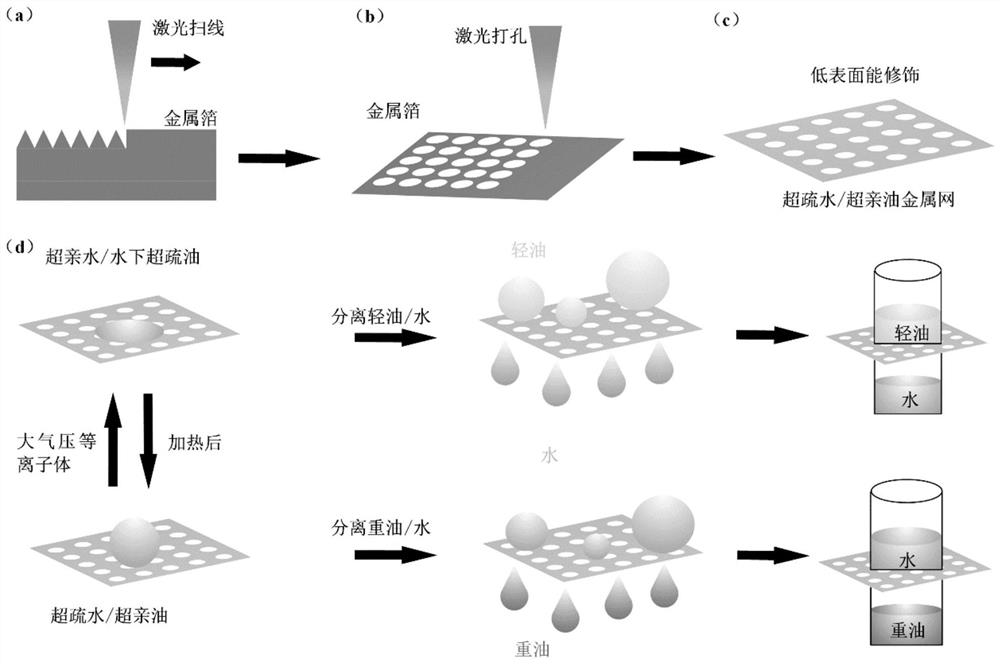

A preparation method of oil-water separation metal mesh with controllable wettability

A technology of oil-water separation and metal mesh, which is applied in separation methods, filtration separation, liquid separation, etc., can solve the problems of cumbersome separation process, impact on human body, and limitation of separation solution, and achieve efficient and convenient process with simple and easy steps , the effect of efficient cycle separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0040] Taking an aluminum foil with a thickness of 110 μm as an example, hexadecane and methylene chloride are used as light oil and heavy oil to be separated, respectively.

[0041] Fix the 3.5×3.5cm aluminum foil on the workbench, the power of the fiber pulse laser is 18W, and the pulse frequency is 20kH Z , the moving speed of the light spot is 200mm / s, the spacing of laser scanning lines is 50 microns, the width of scanning lines is 10 microns, and the number of scanning lines is 1 time. The outer surface of the aluminum foil needs to be processed with the same sweeping parameters.

[0042] The aluminum foil after the line-sweeping treatment is drilled with a laser array, the power of the fiber pulse laser is 24W, and the pulse frequency is 20kH Z , the moving speed of the light spot is 200mm / s, the aperture of the laser drilling is 50 microns, the hole spacing is 100 microns, and the number of laser drilling processing is 1 time, and the aluminum mesh with a microhole ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com