Dry food for dogs and preparation process of dry food for dogs

A dog food, dry type technology, applied in the field of dry dog food and its preparation, can solve the problems of high production cost, poor palatability, poor flavor and the like, and achieve the effects of improving profit, good flavor and improving health status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

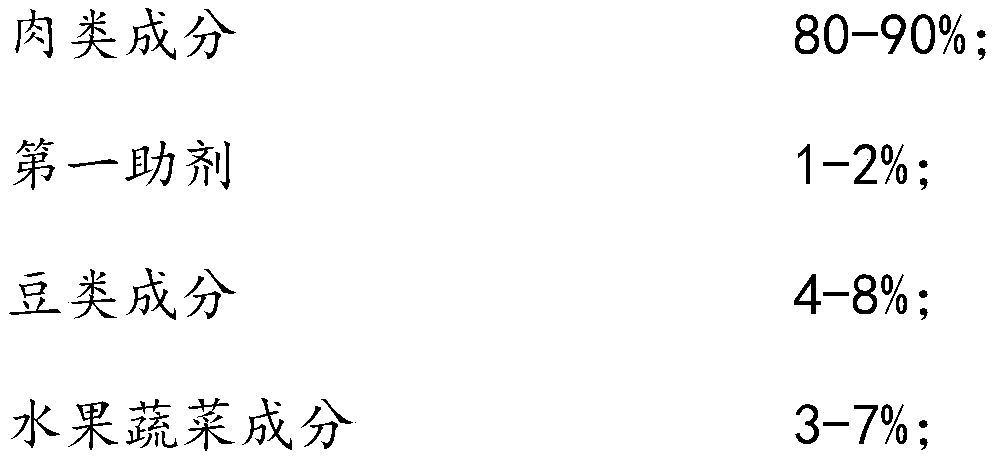

Method used

Image

Examples

Embodiment 1

[0078] A preparation process for dry dog food, comprising the following preparation processes:

[0079] S1: Preparation of the first auxiliary agent:

[0080] 1) Grind 12% freeze-dried beef liver and 18% freeze-dried chicken into powder, add 37.9% pure water, mix well, heat the mixture to 50°C; then add 0.4% sodium dihydrogen phosphate , after stirring evenly, then add 0.5% papain, after mixing evenly, keep warm for 4 hours to prepare A mixed solution;

[0081] 2) After raising the temperature of the prepared mixed solution A to 115°C, add 0.5% citric acid, stir evenly, and keep warm for 50 minutes to prepare the mixed solution B;

[0082] 3) Add 0.7% disodium hydrogen phosphate to the B mixed solution, and stir evenly to prepare the C mixed solution;

[0083] 4) The mixture C was centrifuged for 25 minutes at a speed of 5000r / min. After filtering, 12% of cold-pressed canola oil and 18% of deep-sea fish oil were added to the obtained filtrate. After stirring evenly, the f...

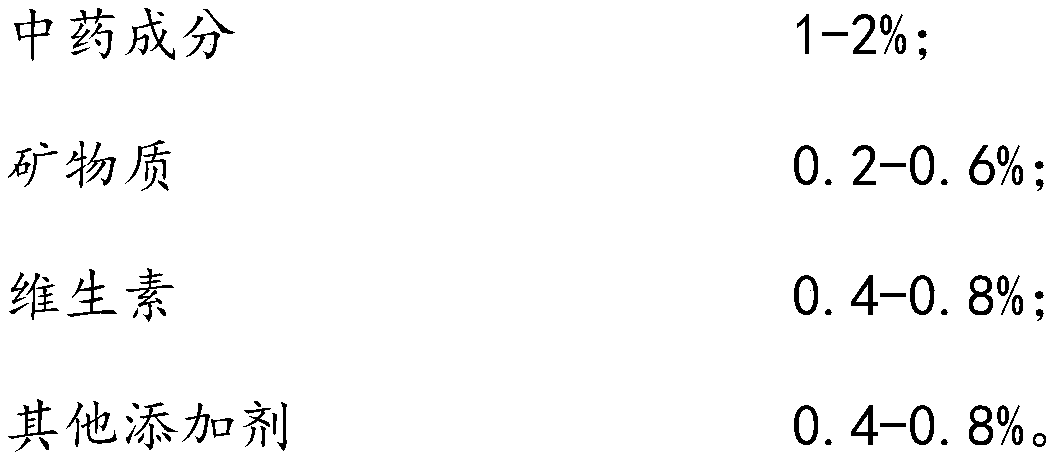

Embodiment 1

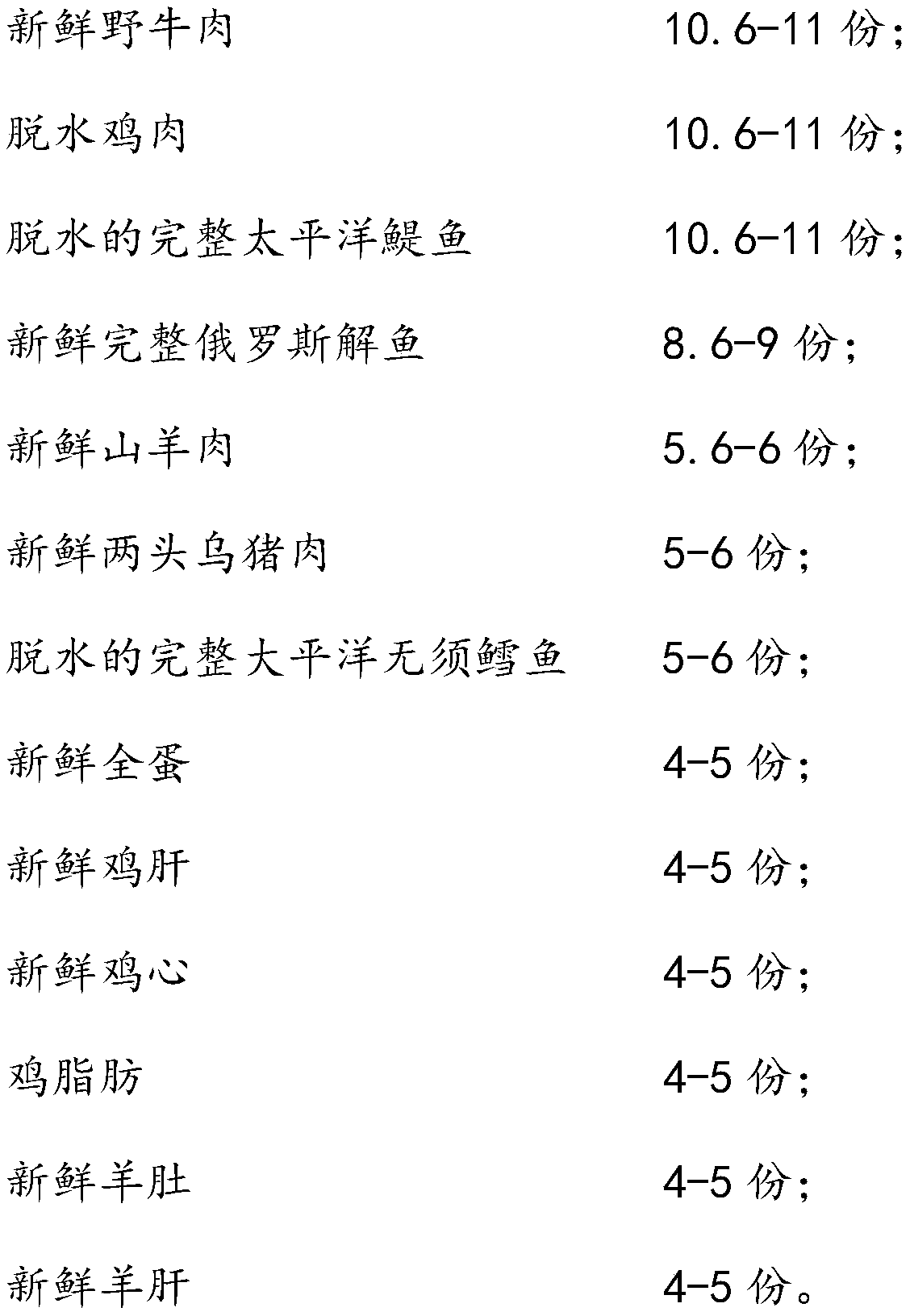

[0101] The difference between embodiments 10-13 and embodiment 1 is that the first auxiliary agent includes the following raw materials in weight percentage:

[0102]

[0103]

[0104] The difference between Examples 14-17 and Example 1 is that the bean ingredients include the following raw materials in parts by weight:

[0105]

[0106] The difference between Examples 18-21 and Example 1 is that the fruit and vegetable components include the following raw materials in parts by weight:

[0107]

[0108]

[0109] The difference between Examples 22-25 and Example 1 is that the Chinese medicine ingredients include the following components in weight percentage:

[0110]

[0111] The difference between Embodiment 26-29 and Embodiment 1 is that the mineral matter comprises the following raw materials in parts by weight:

[0112]

[0113] The difference between embodiments 30-33 and embodiment 1 is that the vitamins include the following raw materials in parts b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com