Self-cleaning flexible composite structure writing carrier

A composite structure and self-cleaning technology, applied in the field of materials, can solve the problems of easy damage, large volume, hard to wipe the surface optical effect of whiteboard writing, etc., and achieve the effect of good hydrophilicity and strong scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

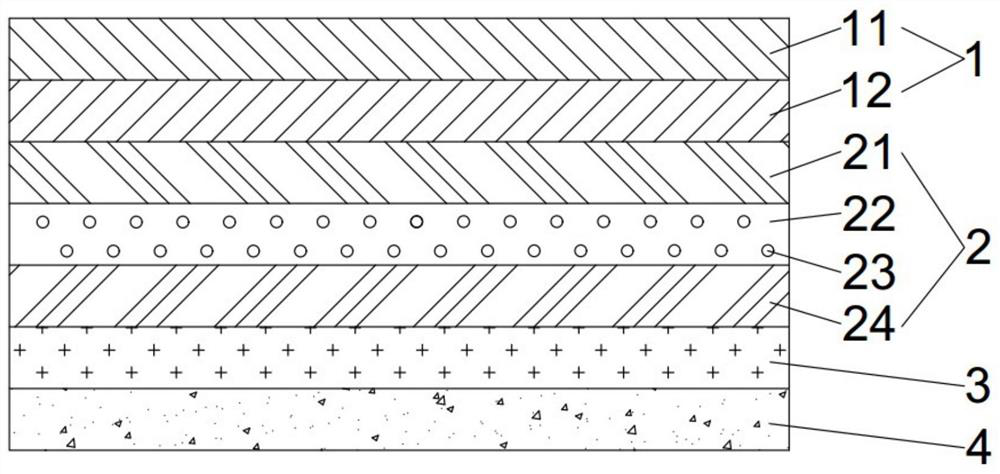

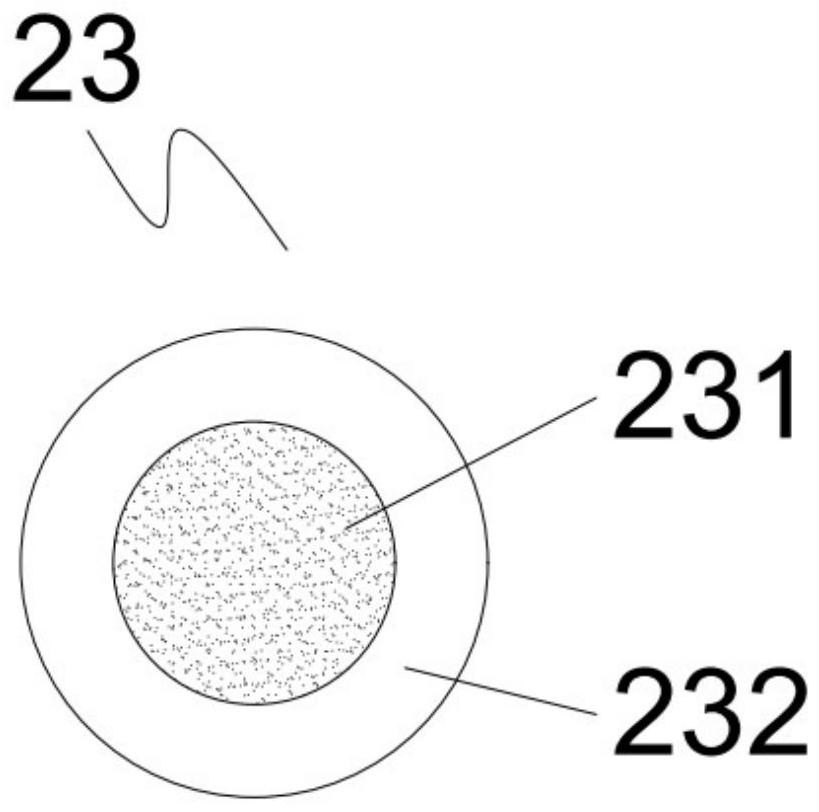

[0055] This embodiment provides a self-cleaning flexible composite structure writing carrier, such as figure 1 As shown, the self-cleaning layer 1 , the optical composite layer 2 , the adsorption layer 3 and the whiteboard 4 are sequentially stacked.

[0056] Such as figure 1 As shown, the self-cleaning layer 1 includes a top coat 11 and an undercoat 12 , and the undercoat 12 is disposed on the surface of the top coat 11 facing the optical composite layer 2 .

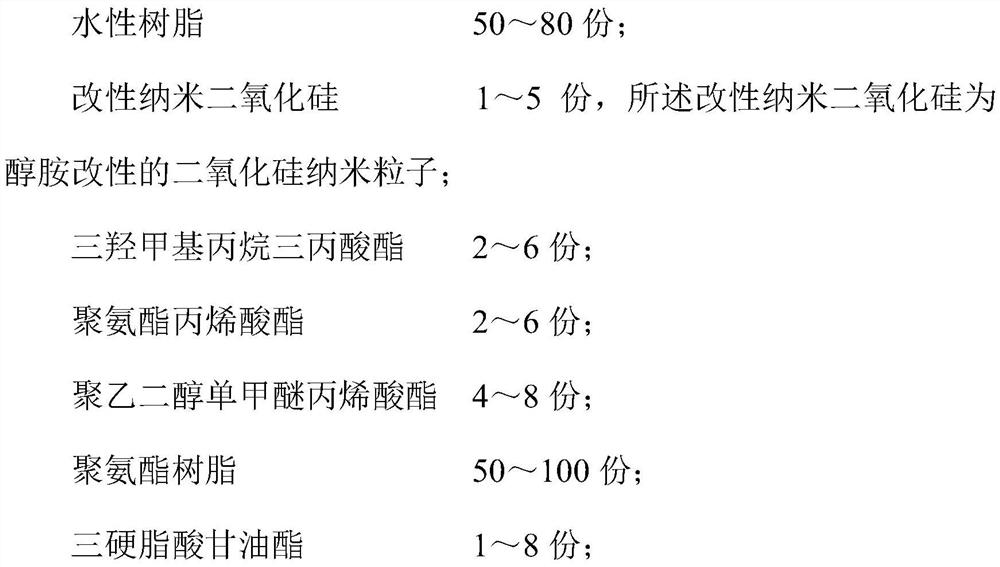

[0057] The top coat 11 includes the following raw materials in parts by weight: 65 parts of water-based resin, 3 parts of modified nano-silica, 4.5 parts of glyceryl tristearate, 5 parts of silane coupling agent, and 65 parts of water-based curing agent.

[0058] Wherein, the above-mentioned water-based resin is made of monomers of 2-hydroxyethyl methacrylate, hydroxypropyl acrylate, butyl acrylate, 4-hydroxybutyl acrylate and styrene in a molar ratio of 10:6:6:3: 15 copolymerized.

[0059] The above-mentioned modifi...

Embodiment 2

[0076] This embodiment provides a writing carrier with a self-cleaning flexible composite structure, which includes a self-cleaning layer 1 , an optical composite layer 2 , an adsorption layer 3 and a whiteboard 4 which are sequentially stacked.

[0077] The self-cleaning layer 1 includes a top coat 11 and an undercoat 12 , and the undercoat 12 is disposed on the surface of the top coat 11 facing the optical composite layer 2 .

[0078] The top coat 11 includes the following raw materials in parts by weight: 60 parts of water-based resin, 1 part of modified nano-silica, 1 part of glyceryl tristearate, 2 parts of silane coupling agent, and 50 parts of water-based curing agent.

[0079] Wherein, the above-mentioned water-based resin is made of monomers of 2-hydroxyethyl methacrylate, hydroxypropyl acrylate, butyl acrylate, 4-hydroxybutyl acrylate and styrene in a molar ratio of 8:4:2:1: 10 copolymerized.

[0080] The above-mentioned modified nano silicon dioxide is silicon diox...

Embodiment 3

[0097] This embodiment provides a writing carrier with a self-cleaning flexible composite structure, which includes a self-cleaning layer 1 , an optical composite layer 2 , an adsorption layer 3 and a whiteboard 4 which are sequentially stacked.

[0098] The self-cleaning layer 1 includes a top coat 11 and an undercoat 12 , and the undercoat 12 is disposed on the surface of the top coat 11 facing the optical composite layer 2 .

[0099] The top coat 11 includes the following raw materials in parts by weight: 80 parts of water-based resin, 5 parts of modified nano-silica, 8 parts of glyceryl tristearate, 8 parts of silane coupling agent, and 80 parts of water-based curing agent.

[0100] Wherein, the above-mentioned water-based resin is made of monomers of 2-hydroxyethyl methacrylate, hydroxypropyl acrylate, butyl acrylate, 4-hydroxybutyl acrylate and styrene in a molar ratio of 12:8:10:5: 20 copolymerization.

[0101] The above-mentioned modified nano silicon dioxide is silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com