Shield mud cementing material and preparation method and application thereof

A cementitious material and mud technology, which is applied in the field of shield mud cementitious material and its preparation, can solve the problems of occupying land, transportation difficulties, and environmental pollution by waste shield mud, so as to save production costs, solve environmental pollution, and achieve important Environmental and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

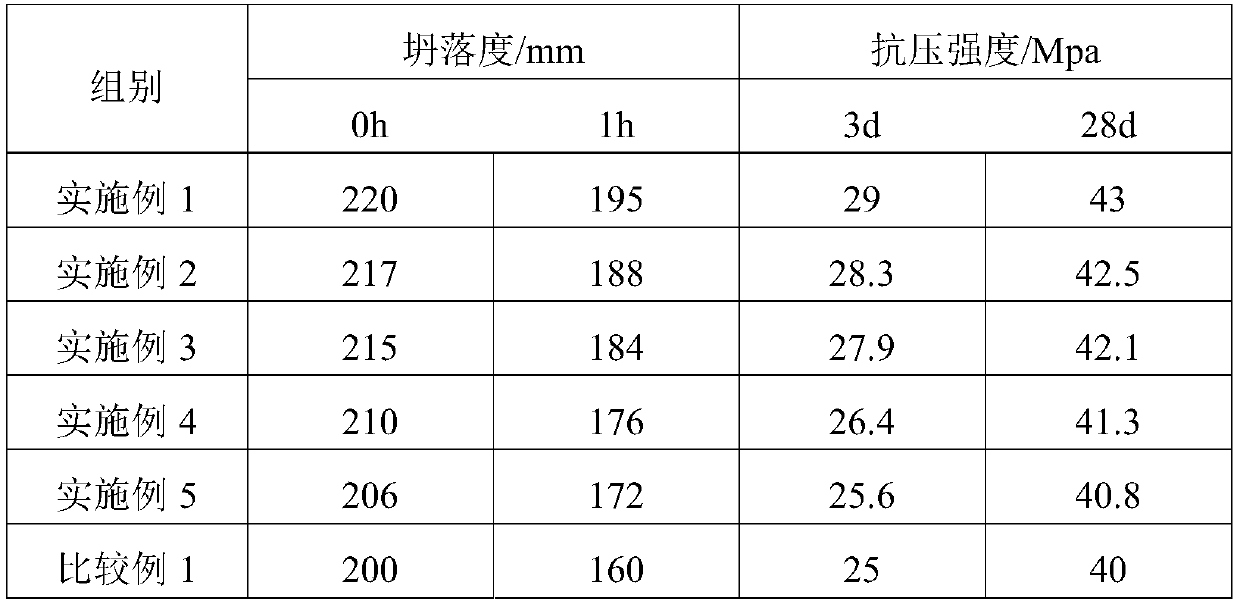

Examples

preparation example Construction

[0022] Embodiments of the present invention also provide a preparation method of shield mud cementitious material, comprising the steps of:

[0023] (1) Each raw material is prepared by weight;

[0024] (2) Mix the waste shield mud, quicklime and active powder uniformly to obtain a mixture A, react the mixture A to a water content ≤ 40%, then mix the mixture A and desulfurized gypsum uniformly to obtain a mixture B, and mix the mixture B at 600 React at ~700°C until the water content of the product is ≤1% to obtain the finished product.

[0025] In the present invention, since the reaction of quicklime, active powder and water and acid substances in the shield mud will release heat, the mixture A is reacted at normal temperature until the water content is ≤40%.

[0026] In some preferred implementations of the present invention, the mixture A is reacted to a water content of 15-35% to ensure that the mixture A and desulfurized gypsum can fully react, reduce energy consumption...

Embodiment 1

[0034] Embodiment 1 of the present invention provides a kind of shield mud cementitious material, and it comprises the component of following parts by weight: waste shield mud (water content 80%) 7 parts, quicklime 2 parts, construction waste micropowder 1 part and 0.5 parts of desulfurized gypsum.

[0035] The shield mud is prepared by the following method:

[0036] (1) Quicklime, construction waste micropowder and desulfurized gypsum are respectively ground and sieved with a 200-mesh sieve until the remaining 8.2% of quicklime 200-mesh sieve, 14.8% of construction waste micropowder 200-mesh sieve, desulfurized gypsum 200 The remaining 9.1% was sieved by the mesh sieve, and the sieved quicklime, construction waste micropowder and waste shield mud were stirred and mixed evenly to obtain mixture A;

[0037] (2) After the mixture A was reacted at normal temperature for 20 minutes, the water content of the mixture A was reduced to 30%, and then the mixture A was stirred and mixe...

Embodiment 2

[0039] Embodiment 2 of the present invention provides a kind of shield mud cementitious material, and it comprises the component of following parts by weight: waste shield mud (water content 85%) 6 parts, quicklime 1.5 parts, construction waste micropowder 0.8 part and 0.35 parts of desulfurized gypsum.

[0040] The shield mud is prepared by the following method:

[0041] (1) Grinding quicklime, construction waste micropowder and desulfurized gypsum respectively and sieving with a 200-mesh sieve until the remaining 10% of quicklime 200 mesh sieve, 15% of construction waste micropowder 200 mesh sieve, and 200 mesh desulfurization gypsum The remaining 10% was sieved through the mesh sieve, and the sieved quicklime, construction waste micropowder and waste shield mud were stirred and mixed evenly to obtain mixture A;

[0042] (2) After the mixture A was reacted at normal temperature for 25 minutes, the water content of the mixture A was reduced to 35%, and then the mixture A was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com