Self-adhesive polymer modified asphalt waterproof coiled material and preparation method and application thereof

A technology for modifying asphalt and waterproofing membranes, applied in chemical instruments and methods, building structures, building thermal insulation materials, etc. and other problems, to achieve the effect of improving acid and alkali resistance and bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

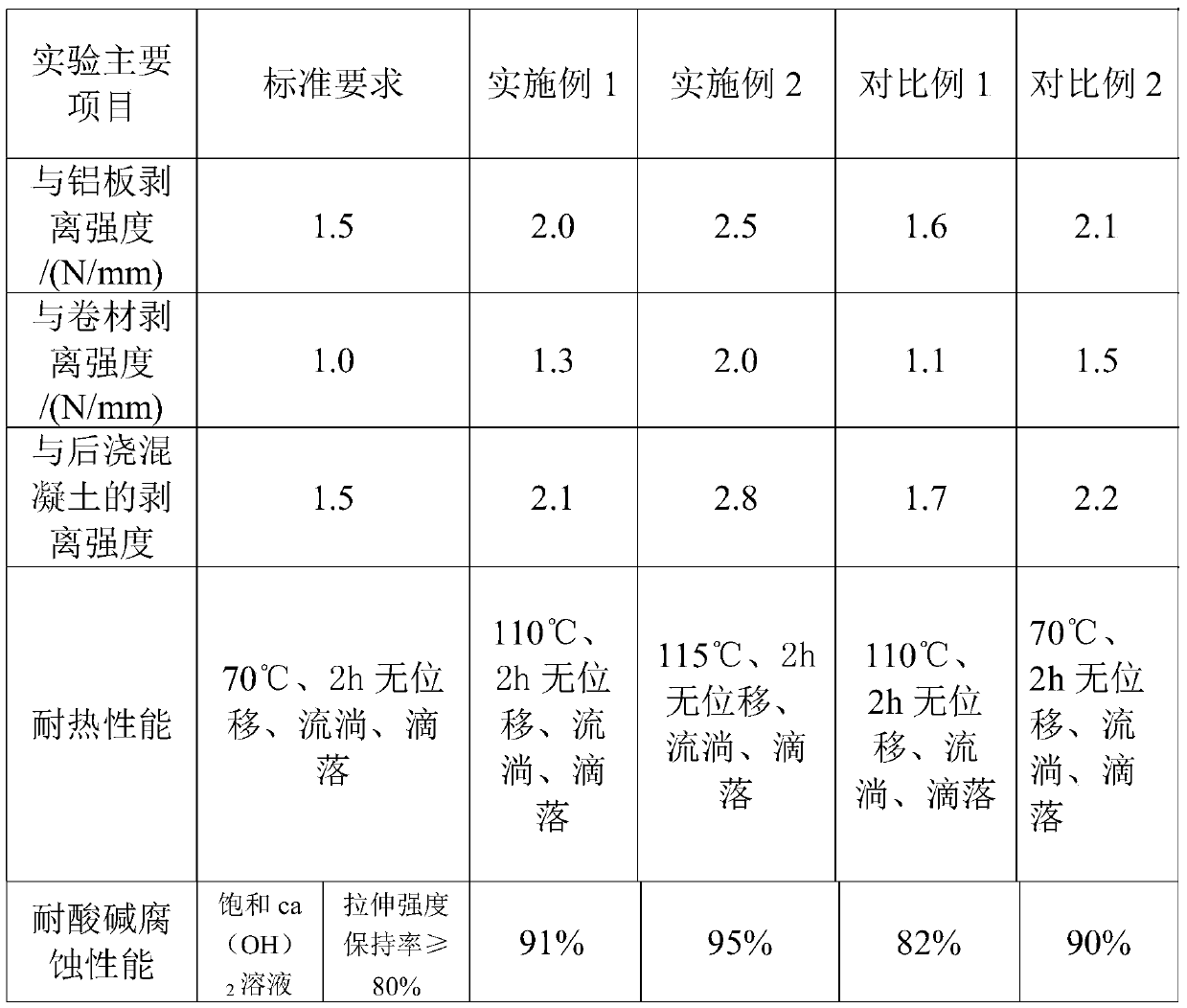

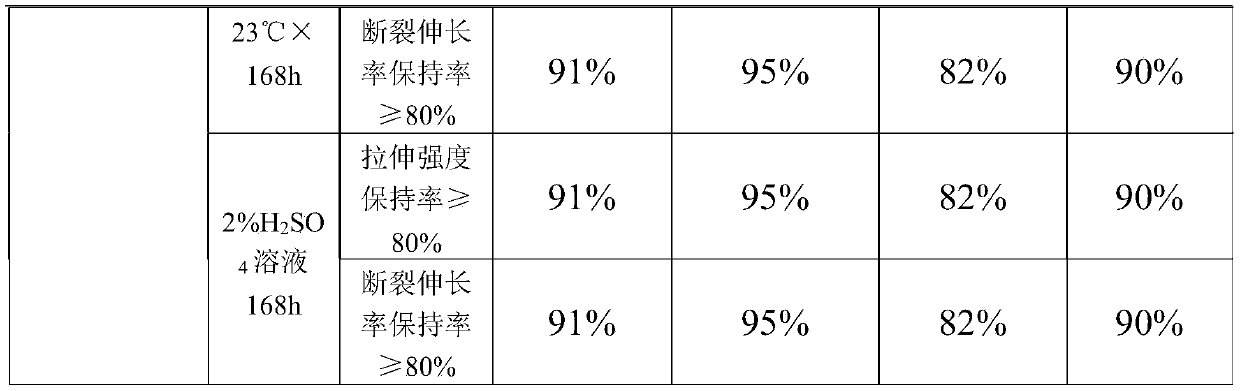

Examples

Embodiment 1

[0030] A corrosion-resistant high-viscosity self-adhesive polymer-modified bitumen waterproofing membrane, in parts by weight, is composed of the following raw materials: 35 parts of Road Oil No. 70 asphalt, 10 parts of aromatic oil, 2 parts of SBR modifier, and 5 parts of SBS parts, 8 parts of activated rubber powder, 2 parts of anti-corrosion tackifier, 10 parts of tackifier resin, 3 parts of TPV resin, and 15 parts of filler.

[0031] The tackifying resin is hydrogenated rosin resin, and the filler is 800-1200 mesh light calcium powder.

[0032] The anti-corrosion tackifier is a flexible vinyl resin;

[0033] The TPV resin is thermoplastic EPDM resin.

[0034] The aromatic hydrocarbon oil has an aromatic hydrocarbon content of ≥85%. The SBR modifier is thermoplastic styrene-butadiene rubber, and its ash content is less than or equal to 55%. The SBS is a styrene-butadiene-styrene block copolymer, the model is 4402; its melt index is 0.13-0.16 g / 10min. The activated rubbe...

Embodiment 2

[0046] A corrosion-resistant high-viscosity self-adhesive polymer-modified bitumen waterproofing membrane, in parts by weight, is composed of the following raw materials: 40 parts of No. 70 asphalt of road oil, 15 parts of aromatic oil, 5 parts of SBR modifier, and 8 parts of SBS parts, 10 parts of activated rubber powder, 5 parts of anti-corrosion tackifier, 15 parts of tackifying resin, 5 parts of TPV resin, and 20 parts of filler.

[0047] The tackifying resin is hydrogenated rosin resin, and the filler is 800-1200 mesh light calcium powder.

[0048] The anti-corrosion tackifier is a flexible vinyl resin;

[0049] The TPV resin is thermoplastic EPDM resin.

[0050] The aromatic hydrocarbon oil has an aromatic hydrocarbon content of ≥85%. The SBR modifier is thermoplastic styrene-butadiene rubber, and its ash content is less than or equal to 55%. The SBS is a styrene-butadiene-styrene block copolymer, its model is 4402, and its melt index is 0.13-0.16 g / 10min. The activa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com