Degradable magnesium alloy and preparation method thereof

A magnesium alloy and alloy liquid technology, applied in the field of degradable magnesium alloy and its preparation, can solve the problems of poor mechanical properties, hard and brittle, slow, etc., to reduce the chance of infection and inflammation, improve the symptoms of osteoporosis, and overcome emphysema Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

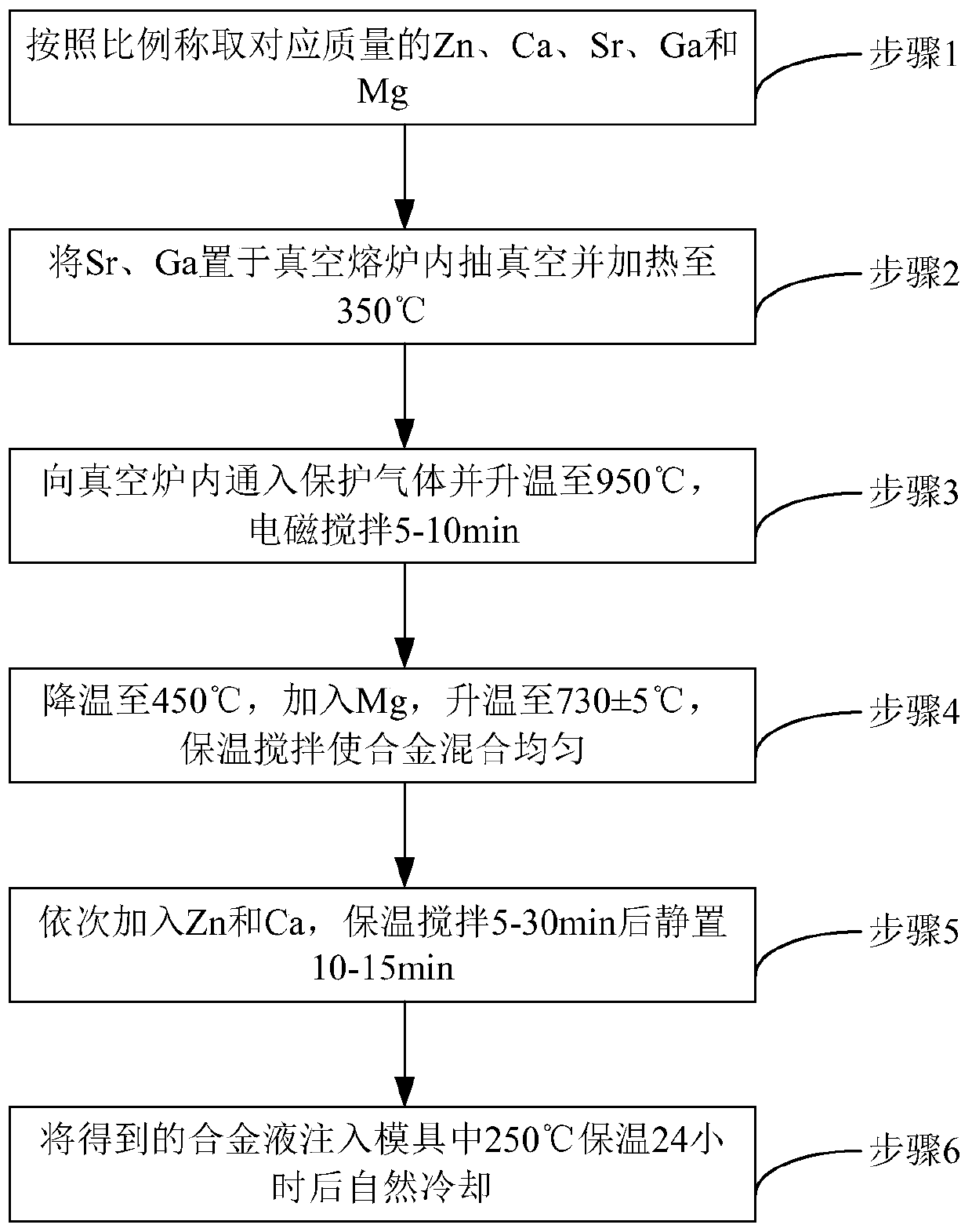

Method used

Image

Examples

Embodiment 1

[0026] What described in embodiment 1 of the present invention is a kind of degradable magnesium alloy, and this magnesium alloy comprises the component of following mass percentage:

[0027] Zn, 1-4%; Ca, 0.5-4%; Sr, 0.1-0.9%; Ga, 0.3-2%; the rest is Mg element and unavoidable impurities.

[0028] First, as a new type of orthopedic material, magnesium metal has a modulus and density closer to bone tissue, and its strength and plasticity are far superior to current bioceramics, calcium sulfate, plastics and other absorbable materials. Second, good biocompatibility: Magnesium is an essential element for normal life activities and metabolic processes of the human body. The total magnesium content of a normal adult body is about 25g, of which 60%-65% exists in bones and teeth, and 27% is distributed in in soft tissue. Magnesium affects a variety of biological functions of cells, such as affecting the transport of potassium ions and calcium ions, regulating signal transmission; p...

Embodiment 2

[0031]A degradable magnesium alloy, the only difference from Example 1 is that it includes the following components in mass percentage: Zn, 1-2%; Ca, 0.5-4%; Sr, 0.1-0.9%; Ga, 0.3-2% %; the rest is Mg element and unavoidable impurities.

Embodiment 3

[0033] A degradable magnesium alloy, the only difference from Example 1 is that it includes the following components in mass percentage: Zn, 2-3%; Ca, 0.5-4%; Sr, 0.1-0.9%; Ga, 0.3-2% %; the rest is Mg element and unavoidable impurities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com