Facing layer firmly combined and integrated modular exterior wall board and manufacturing method thereof

A firmly combined and modular technology, applied in building structures, building components, buildings, etc., can solve the problems of weak bonding, low dimensional accuracy, easy to fall off, etc., to achieve convenient high-precision molding, simple molding process, and guaranteed size The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

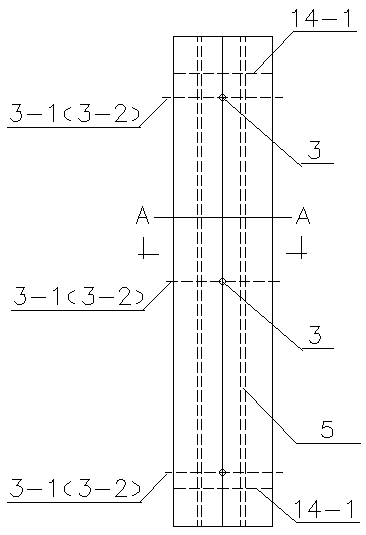

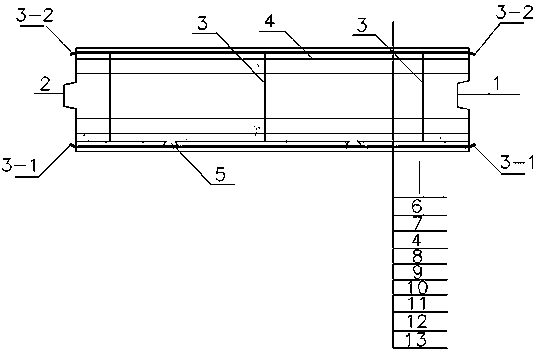

[0038] Embodiment 1: An integrated modular exterior wall panel with a firm combination of facing layers, which consists of a cement mortar layer 6, a fine stone concrete layer 7, a steel wire mesh 4, and a fine stone concrete layer 2 8 from the inside to the outside. , thermal insulation layer 9, fine stone concrete layer three 10, steel wire mesh two 11, fine stone concrete layer four 12, and marble veneer layer 13.

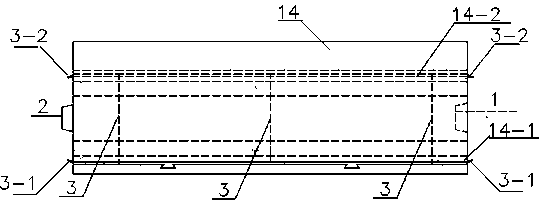

[0039] Reinforcing rib 1 3-1 runs through the fine stone concrete layer 4 along the horizontal direction of the plate, and reinforcing rib 2 3-2 runs horizontally along the plate in the fine stone concrete layer 1, and the two ends of reinforcing rib 1 and reinforcing rib 2 Both of them are bent to the same side of the main body of the reinforcing rib at a certain angle with the main body of the reinforcing rib, and respectively protrude a certain length from the left and right ends of the main body of the plate, and the two ends of the same reinforcing rib are i...

Embodiment 2

[0047] Embodiment 2: An integrated modular exterior wall panel with a firm combination of facing layers, which consists of a cement mortar layer 6, a fine stone concrete layer 7, a steel wire mesh 4, and a fine stone concrete layer 2 8 from the inside to the outside. , thermal insulation layer 9, fine stone concrete layer three 10, steel wire mesh two 11, fine stone concrete layer four 12, metal finish layer 13, and the left and right ends (horizontal direction) of the metal plate 13 are bent into " ", that is, the left and right ends are U-shaped, and the two ends are respectively inserted into the fine stone concrete.

[0048] Reinforcing rib 1 3-1 runs through the fine stone concrete layer 12 horizontally along the horizontal direction of the plate, and reinforcing rib 2 3-2 runs horizontally along the plate in the fine stone concrete layer 1 7, and reinforcing rib 1 and reinforcing rib 2 Both ends are bent to the same side of the main body of the reinforcing rib at a cert...

Embodiment 3

[0053] Embodiment 3: A manufacturing method of an integrated modular exterior wall panel with a firm combination of facing layers, which is completed in the factory. Before forming, the form of the connection interface at the left and right ends of the panel is determined, and the corresponding molding is determined according to the form of the connection interface. template.

[0054] The method includes: 1. Bonding the structural member 15 in the reinforcement groove inside the surface layer, so that the first side of the structural member fits the inner surface of the surface layer, the second side fits the side wall of the reinforcement groove, and the third side fits the reinforcement groove The bottom surface of the reinforcement groove, and the whole structure is arranged along the cross-section of the reinforcement groove.

[0055] 2. Fix the outer layer of the inner surface layer and the outer layer of the fixed structural parts of the inner surface reinforcement groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com