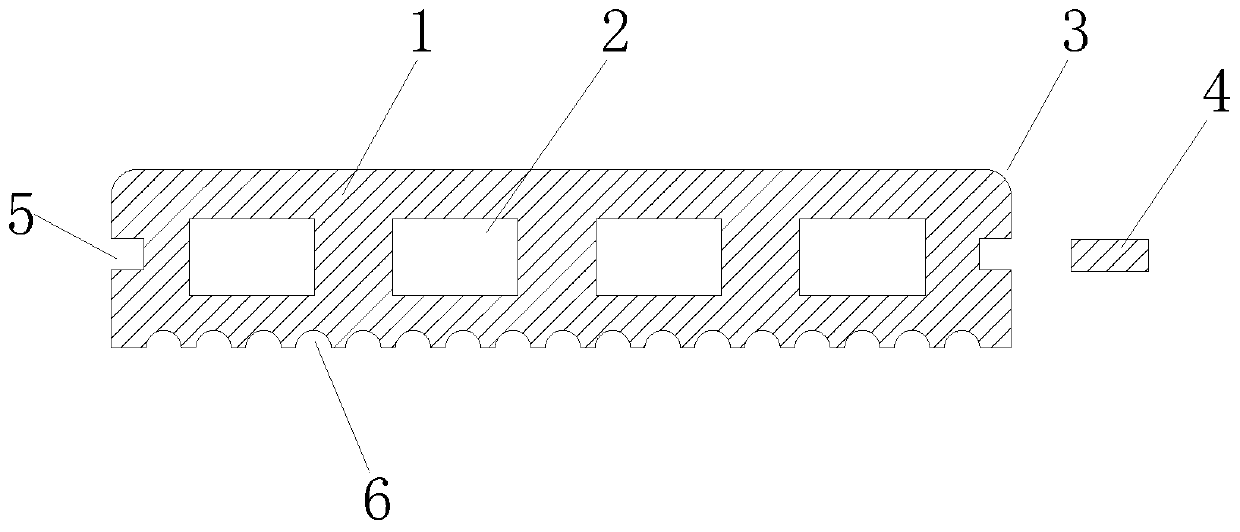

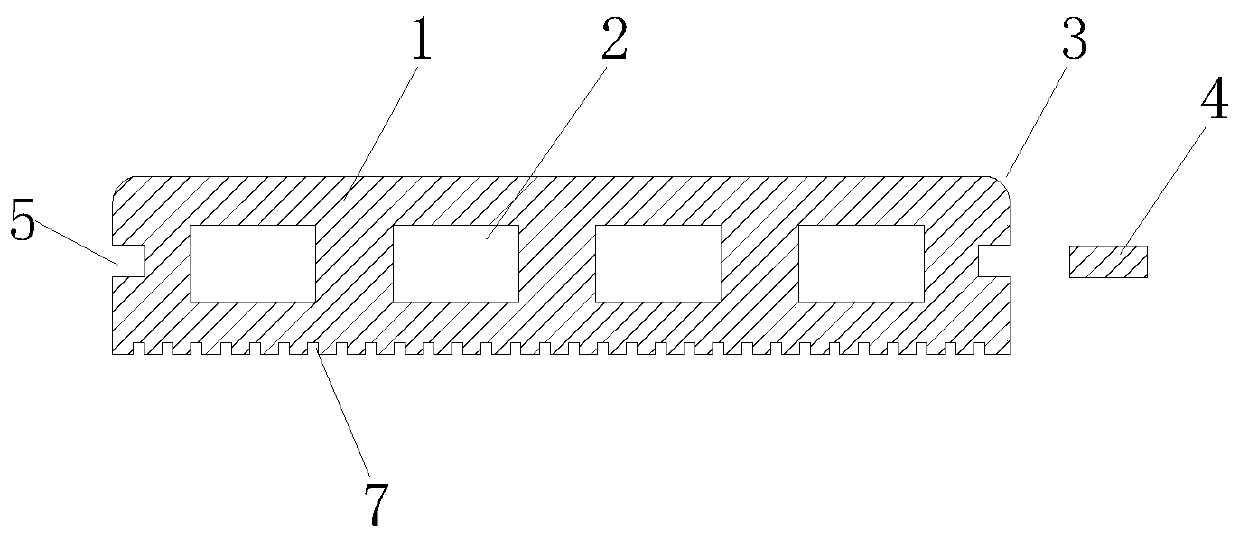

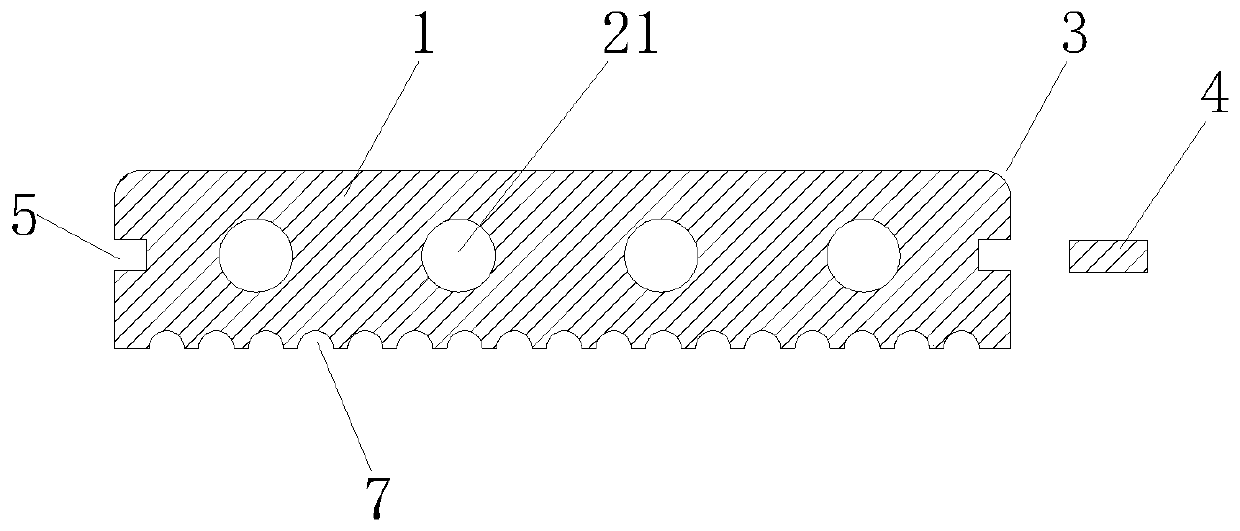

Outdoor insect preventing and aging resisting wood plastic floor and processing method

A technology of wood-plastic floor and processing method, which is applied in the direction of coating, construction, building structure, etc., can solve the problems of easy corrosion, easy moth, limited application scope, etc., and achieve the effect of high hardness and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0052] A method for processing an outdoor durable wood-plastic anti-corrosion floor, comprising the following steps:

[0053] (1) Making ingredients: The ingredients are wood-plastic additives, compatibilizers, antioxidants, talcum powder, light calcium carbonate, preservatives, ultraviolet absorbers and fuels mixed in proportion.

[0054] (2) Send the plastic particles of 25% (weight) of raw materials, the wood powder of 50% (weight) and the batching of 25% (weight) into a high-temperature mixer, and fully stir 10Min at a temperature of 106°C and a rotating speed of 460r / Min. A mixture is obtained.

[0055] (3) Form the mixed material into a new material, put it in the cooling machine, the cooling temperature is 40-45°C, the cooling time is 70Min, and the cooling is formed.

[0056] (3) Put the mixed and cooled materials into the threaded single-rod wood-plastic extruder and pass through different types of product molds to extrude and extrude shaped products.

[0057] (4) E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com