Air control delay device for fire extinguishing control system

A technology of a control system and a delay device, applied in fire rescue and other directions, can solve the problems of inappropriate restoration of the original state, disorder of the delay control program, affecting the delay action, etc., so as to reduce the impact of manufacturing, installation and operation accuracy, Reduce casualties and property losses, and achieve the effect of time delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

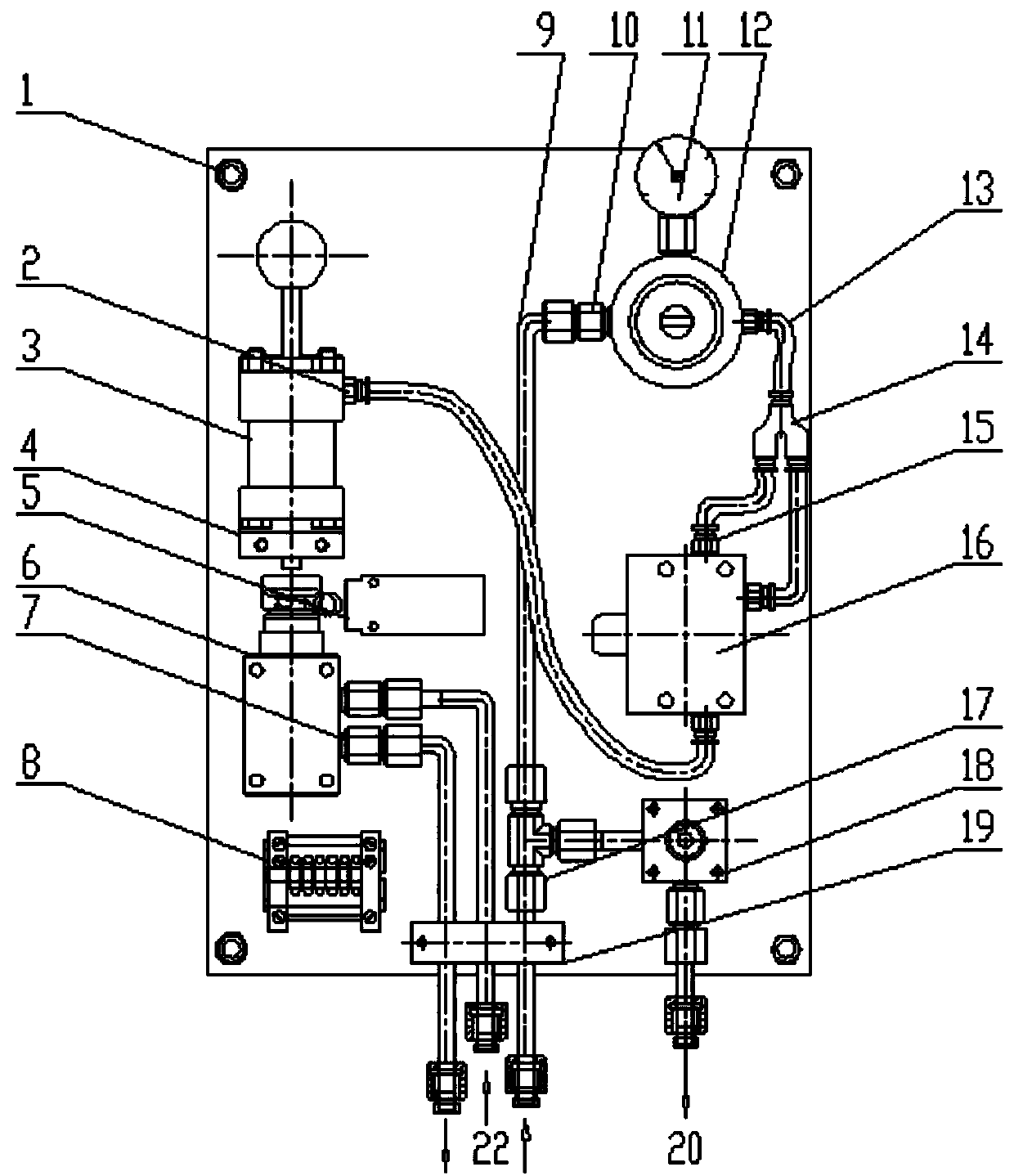

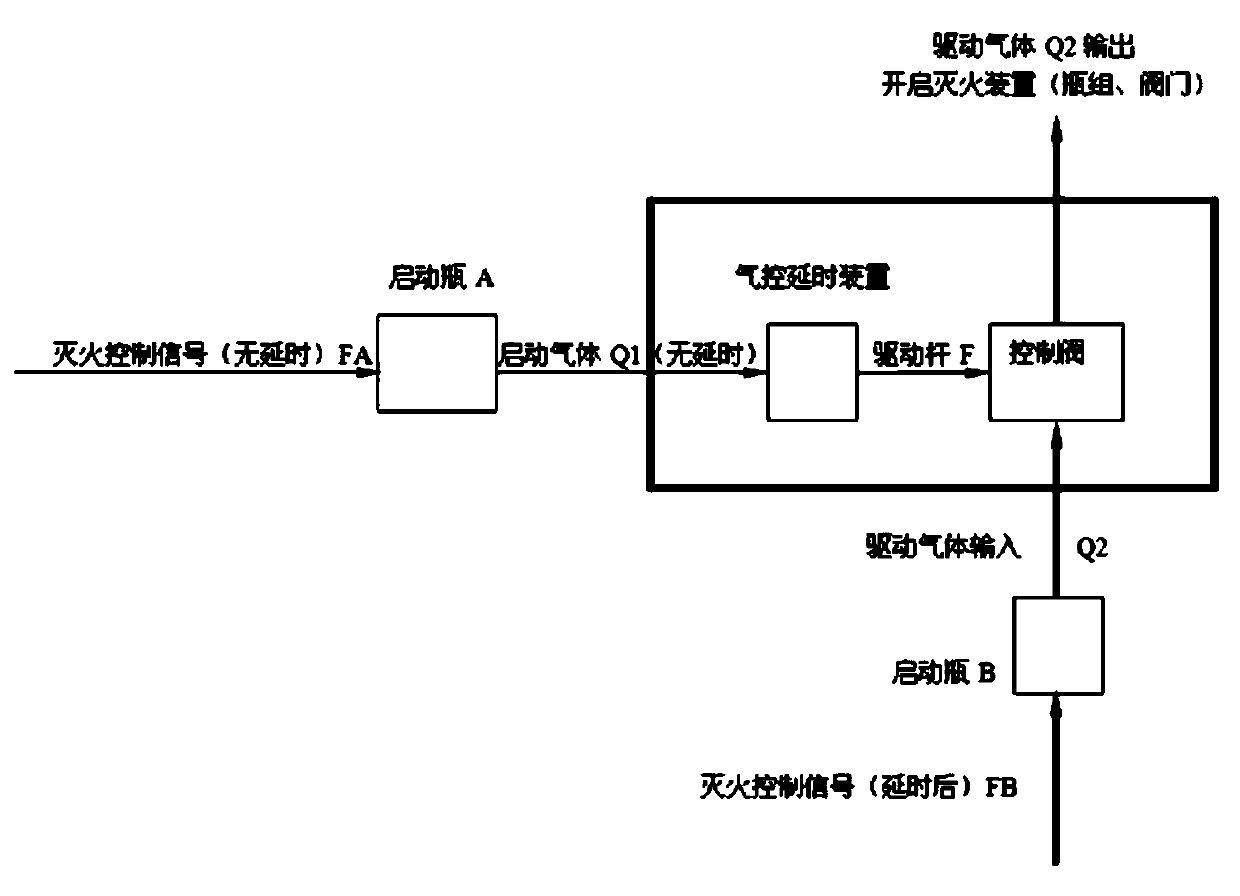

[0021] combined with Figure 1-2 The air-controlled delay device for the fire extinguishing control system includes an installation base plate 1, an action cylinder 3 fixed on one side of the installation base plate 1, and a two-position two-way straight-through valve 6, which are fixed on the other side of the installation base plate 1 Pressure reducing valve 12, air-controlled timer 16, two-position two-way manual reversing valve 18, two-position two-way straight-through valve 6 is arranged directly above the action cylinder 3, and the piston rod of the action cylinder 3 is directly connected to the two-position two-way The axis of the valve 6 coincides, and there is a distance gap between the action end of the two-position two-way straight-through valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com