Thermal response core-shell structure fire extinguishing agent applicable to lithium ion battery and preparation method of thermal response core-shell structure fire extinguishing agent

A lithium-ion battery, core-shell structure technology, applied in fire prevention equipment, etc., can solve the problems of long response time, late intervention of fire extinguishing agent capsule core material, unadjustable melting temperature, etc., and achieve the effect of preventing thermal runaway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0020] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them. Example. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

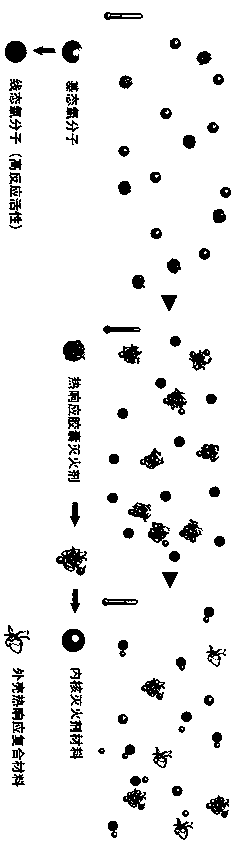

[0021] The invention discloses a heat-responsive core-shell structure fire extinguishing agent suitable for lithium-ion batteries, which includes a shell containing a heat-responsive polymer and an inner core containing a fire extinguishing agent or a flame retardant, and the inner core is wrapped by the shell and forms a Microcapsules, the outer shell of which has a state in which its confo...

Embodiment 1

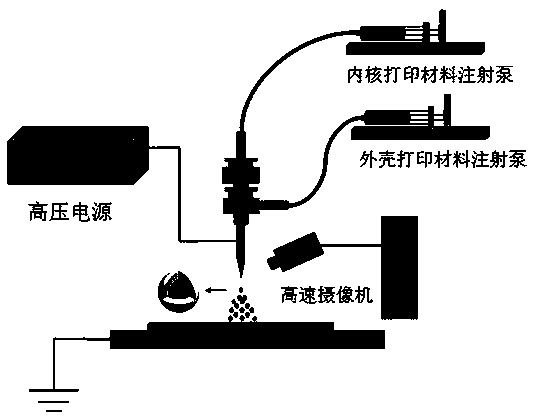

[0036] (1) Preparation of thermoresponsive shell printing solution

[0037]Thermally responsive housing materials include thermally responsive polymers, LCST-tuning polymers, conductive polymers, and organic solvents. In this embodiment, the thermoresponsive polymer is polyvinyl phosphonate diethyl (PDEVP); the LCST regulation polymer is polyvinyl dimethyl phosphate (PDMVP); the conductive polymer is PEDOT; the organic solvent is N, N -Dimethylformamide (DMF). According to the upper limit of the safe window temperature (100°C) of lithium-ion batteries, a thermoresponsive copolymer with an LCST of 100±5°C was prepared. The thermoresponsive copolymer P(DEVP-DPVP) was synthesized based on free radical polymerization with PDMVP and PDEVP at a mass ratio of 0.59:0.41. Mix the prepared copolymer, the conductive polymer PEDOT, and the organic solvent DMF according to a mass ratio of 5:1:8, and mix thoroughly and evenly to obtain the shell printing solution.

[0038] (2) Prepare fi...

Embodiment 2

[0043] (1) Preparation of thermoresponsive shell printing solution

[0044] Thermally responsive housing materials include thermally responsive polymers, LCST-tuning polymers, conductive polymers, and organic solvents. In this example, poly-n-butyl methacrylate (PnBMA) is used as the heat-responsive polymer; polyethylene oxide (plasma electrolytic oxidation, PEO) is used as the LCST regulating polymer; PEDOT is used as the conductive polymer; N, N- Dimethylformamide (DMF). According to the upper limit of the safe window temperature (100°C) of lithium-ion batteries, a thermoresponsive copolymer with an LCST of 100±5°C was prepared. The thermoresponsive copolymer PnBMA-PEO was synthesized based on free radical polymerization with PnBMA and PEO at a mass ratio of 0.9:0.1. Mix the prepared copolymer, the conductive polymer PEDOT, and the organic solvent DMF according to the mass ratio of 6:2:9, mix thoroughly and stir evenly, and the shell printing solution is obtained.

[0045...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com