A bucket wheel stacker and reclaimer

A bucket-wheel stacker-reclaimer and bucket-wheel technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve problems such as difficult vision, poor heavy-duty effect of the baffle plate, and impact on excavation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

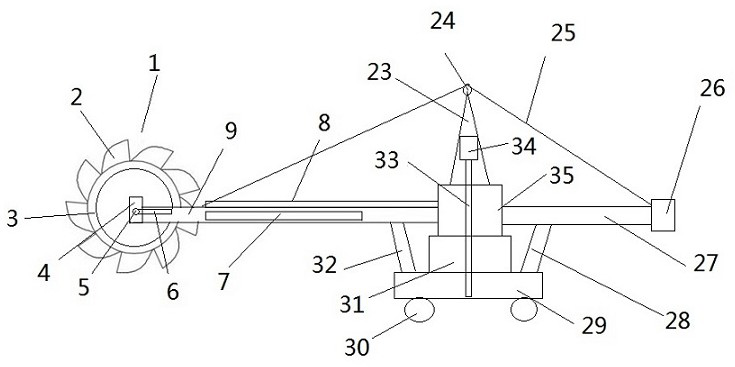

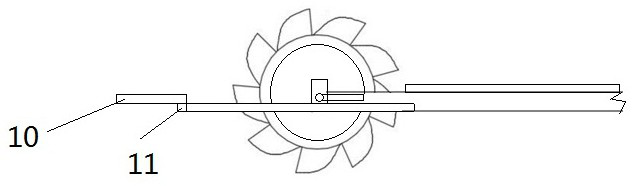

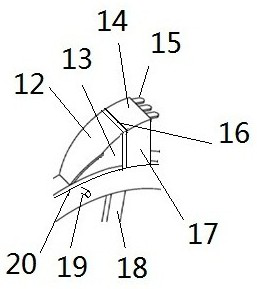

[0043] As shown in the figure: a bucket wheel stacker and reclaimer, including gantry frame, pulley, wire rope, counterweight, counterweight arm, counterweight driving cylinder, base, casters, round seat, pitching mechanism, ladder, cockpit, slewing Mechanism, bucket wheel, motor frame, slider, chute, retractable leveling rod, conveyor belt, bracket, leveling plate, leveling motor; wherein the bucket wheel includes wheel bucket, wheel bucket frame, spokes, turning handle, turning ring The wheel bucket includes a large wheel bucket, a small wheel bucket, gear teeth, and a tie; the tie includes a main body layer and a sealing layer; a round seat is set on the base, a turning mechanism is set on the round seat, and a gantry frame is set on the turning mechanism , the cockpit is set on the side of the gantry, and the bucket wheel stacker and reclaimer is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com