Highly durable environment-friendly granite sink and preparation method thereof

A granite and environmentally friendly technology, applied in the field of building decoration materials, can solve the problems of single color, environmental and labor injury, high energy consumption of stainless steel sinks, and achieve the effect of improving impact resistance, high strength and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

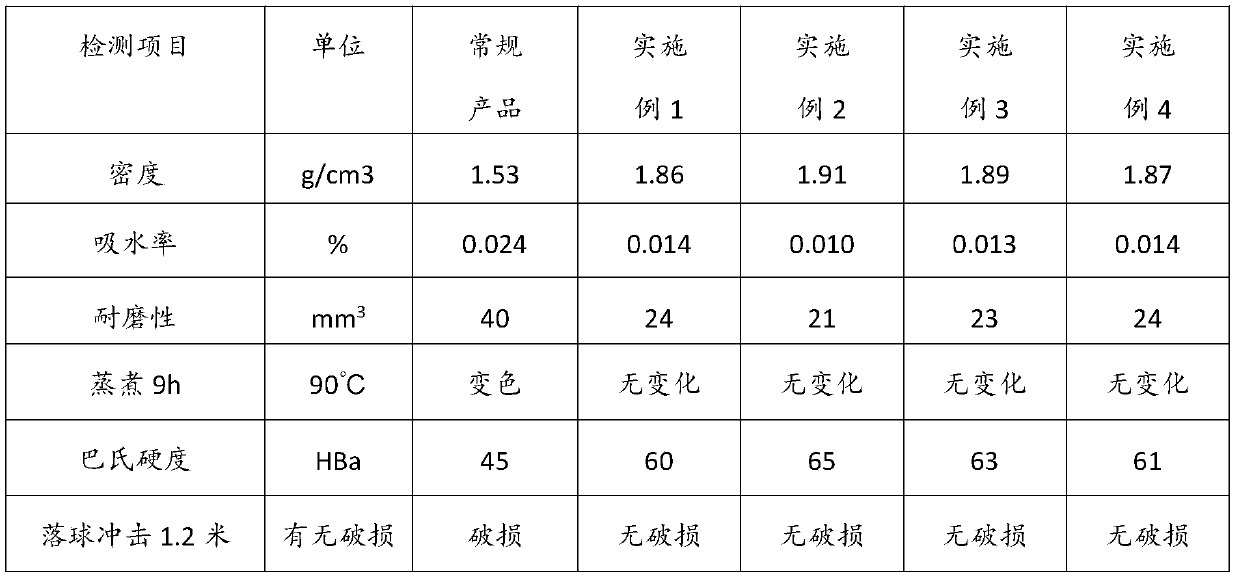

Examples

Embodiment 1

[0023] This embodiment provides a highly durable and environmentally friendly granite water tank. The raw materials in the plate and their weight percentages are: 35% of gelling material, 2.5% of curing agent, 0.3% of accelerator, 1.5% of reinforcing agent, and 4% of waterproofing agent , 5% anti-aging agent, 1.5% toughening agent, 2.4% heat stabilizer, 47.8% filler, 0% toner.

[0024] Wherein, the gel material is composed of the following components by weight percentage: methacrylic acid type vinyl resin 40%, xylene type unsaturated polyester resin 40%, bisphenol A type epoxy acrylic resin 20%; curing agent consists of the following weight The composition of percentage: methyl ethyl ketone peroxide 30%, methyl isobutyl ketone peroxide 35%, acetyl acetone peroxide 15%, cumene hydroperoxide 20%; Accelerator is made up of the following composition of weight percentage: Hexanoic acid 35% cobalt, 25% diethylaniline, 24% dimethyl-p-toluidine, 16% ethoxy-p-toluidine; the reinforcing...

Embodiment 2

[0029] This embodiment provides a highly durable and environmentally friendly granite water tank. The raw materials in the plate and their weight percentages are: 41% gelling material, 1.3% curing agent, 0.1% accelerator, 1% reinforcing agent, and 2% waterproofing agent , 4% anti-aging agent, 1.8% toughening agent, 1.5% heat stabilizer, 46.8% filler, 0.5% toner.

[0030] Wherein, the gel material is composed of the following components by weight percentage: methacrylic acid vinyl resin 35%, xylene type unsaturated polyester resin 37%, bisphenol A type epoxy acrylic resin 27%; curing agent consists of the following weight The composition of percentage: methyl ethyl ketone peroxide 50%, methyl isobutyl ketone peroxide 11%, acetylacetone peroxide 15%, cumene hydroperoxide 24%; Accelerator is made up of the following composition of weight percentage: Hexanoic acid Cobalt 56%, diethylaniline 21%, dimethyl-p-toluidine 13%, ethoxy-p-toluidine 10%; the reinforcing agent is composed of...

Embodiment 3

[0035] This embodiment provides a highly durable and environmentally friendly granite water tank. The raw materials in the plate and their weight percentages are: 31% gelling material, 1.3% curing agent, 0.2% accelerator, 1.7% reinforcing agent, 3.5% waterproofing agent, anti-aging 4.8% agent, 1.8% toughening agent, 2.8% heat stabilizer, 52.2% filler, 0.7% toner.

[0036]Wherein, the gel material is composed of the following components by weight percentage: methacrylic acid vinyl resin 60%, xylene type unsaturated polyester resin 27%, bisphenol A type epoxy acrylic resin 13%; curing agent consists of the following weight: The composition of percentage: methyl ethyl ketone peroxide 31%, methyl isobutyl ketone peroxide 40%, acetylacetone peroxide 12%, cumene hydroperoxide 17%; Accelerator is made up of the following composition of weight percentage: Hexanoic acid 13% cobalt, 34% diethylaniline, 11% dimethyl-p-toluidine, 42% ethoxy-p-toluidine; the reinforcing agent is composed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com