Method for preparing novel aqueous fluorescence polyurethane

A polyurethane, water-based technology, applied in the field of preparation of new water-based fluorescent polyurethane, can solve the problems of polymer fluorescence properties not being systematically researched, fluorescence properties neglected, etc., and achieve the effects of high stability, low cost and reasonable preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

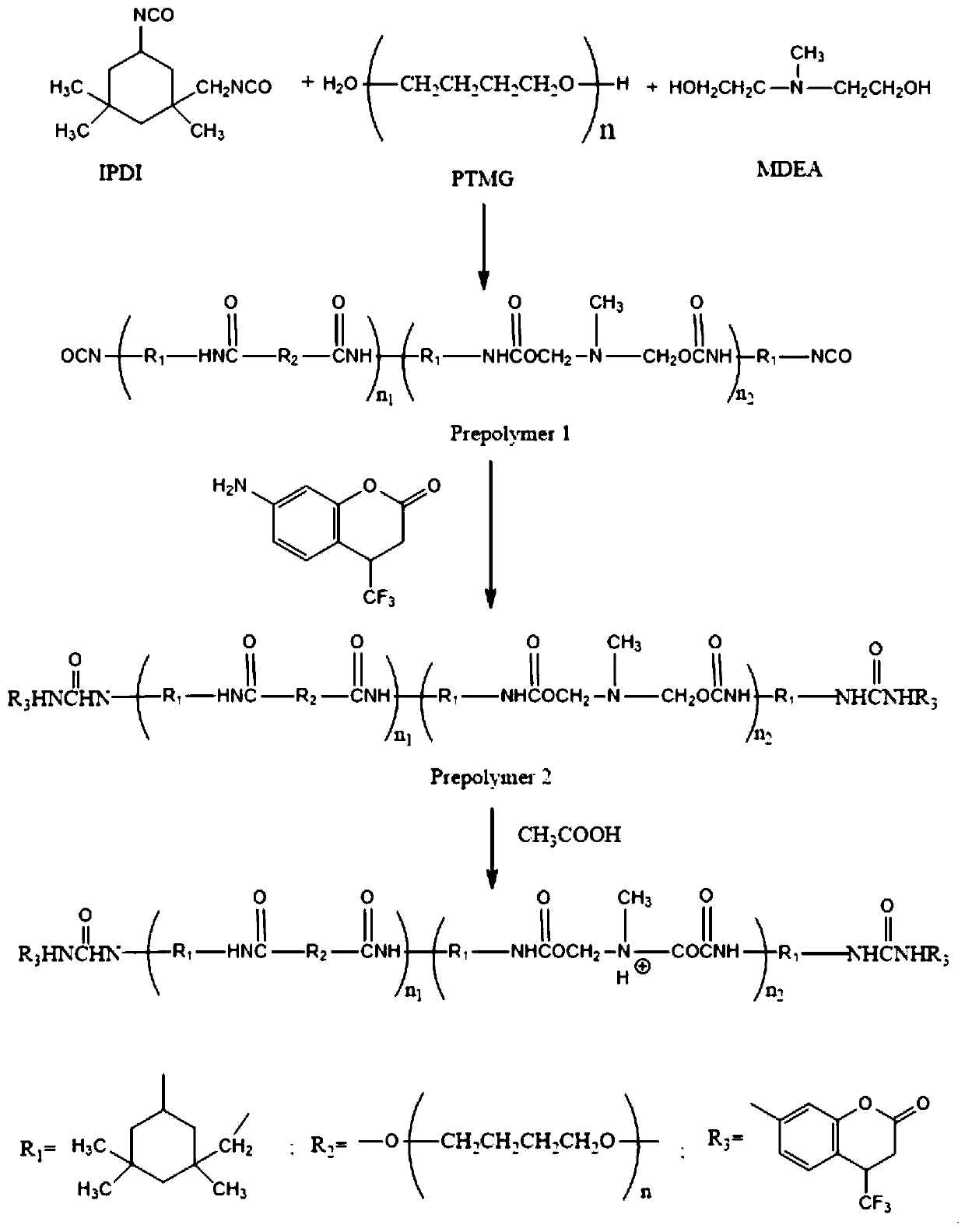

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a novel water-based fluorescent polyurethane. Before the preparation, the isophorone diisocyanate is vacuum-dried at 60° C. for 12 hours before use. The acetic acid was dried in 4 Å molecular sieves for 24 h before use.

[0030] When preparing, take a 250 mL flask equipped with a reflux condenser, a mechanical stirring rod, a thermometer and a nitrogen inlet, and prepare according to the following steps:

[0031] (1) Inflate nitrogen, add metered isophorone diisocyanate, polytetramethylene ether glycol and methyldiethanolamine under the protection of nitrogen, heat the mixture to 70°C, add stannous octoate dropwise as a catalyst, Stir until the NCO content in the system reaches the theoretical value (determined by di-n-butylamine titration); the molar mass ratio of isophorone diisocyanate, polytetramethylene ether glycol and methyldiethanolamine is 1:0.3 : 0.15; organotin catalysts account for 0.01% of the total weight by weight;

[0032] (2) Co...

Embodiment 2

[0038] A method for preparing a novel water-based fluorescent polyurethane. Before the preparation, the isophorone diisocyanate is vacuum-dried at 60° C. for 24 hours before use. The acetic acid was dried in 4 Å molecular sieves for 48 h before use.

[0039] When preparing, take a 250 mL flask equipped with a reflux condenser, a mechanical stirring rod, a thermometer and a nitrogen inlet, and prepare according to the following steps:

[0040] (1) Inflate nitrogen, add metered isophorone diisocyanate, polytetramethylene ether glycol and methyldiethanolamine under the protection of nitrogen, heat the mixture to 100°C, add di(dodecyl Sulfur) dibutyltin as a catalyst, stirring until the NCO content in the system reaches the theoretical value (measured by di-n-butylamine titration); wherein the isophorone diisocyanate, polytetramethylene ether glycol and methyldiethanolamine The molar mass ratio is 1:0.5:0.45; the organotin catalyst accounts for 0.05% of the total weight by weight...

Embodiment 3

[0047] A method for preparing a novel water-based fluorescent polyurethane. Before the preparation, the isophorone diisocyanate is vacuum-dried at 60° C. for 18 hours before use. The acetic acid was dried in 4 Å molecular sieves for 36 h before use.

[0048] When preparing, take a 250 mL flask equipped with a reflux condenser, a mechanical stirring rod, a thermometer and a nitrogen inlet, and prepare according to the following steps:

[0049] (1) Fill with nitrogen, add metered isophorone diisocyanate, polytetramethylene ether glycol and methyldiethanolamine under the protection of nitrogen, heat the mixture to 90 ° C, drop dibutyltin diacetate as a catalyst , stirring until the NCO content in the system reaches the theoretical value (determined by di-n-butylamine titration); wherein the molar mass ratio of isophorone diisocyanate, polytetramethylene ether glycol and methyldiethanolamine is 1: 0.4:0.2; organotin catalyst by weight, accounting for 0.04% of the total weight;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com