Conjugated microporous polymer based on 1,3,5-tribenzaldehyde and preparation method of conjugated microporous polymer

A benzotrialdehyde and conjugated microporous technology, which is applied in the field of conjugated microporous polymers and their preparation, can solve the problems of high experimental cost and the like, and achieve the effects of good thermal stability performance, ultraviolet absorption performance and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention provides a method for preparing a conjugated microporous polymer described in the above scheme, comprising the following steps:

[0032] 2,4,6-trimethyl-1,3,5-triazine and 1,3,5-benzenetricarbaldehyde undergo condensation reaction under the action of base catalysis to obtain the conjugated microporous polymer.

[0033] In the present invention, the reaction formula of the condensation reaction is shown in formula II:

[0034]

[0035] In the present invention, the molar ratio of 2,4,6-trimethyl-1,3,5-triazine to 1,3,5-benzenetricarbaldehyde is 1:1. In the present invention, the base is preferably potassium hydroxide; the molar ratio of the base to 1,3,5-benzenetricarbaldehyde is preferably 3-4:0.8-1.2, more preferably 3.6:1. In the present invention, the solvent for the condensation reaction is preferably anhydrous methanol and / or absolute ethanol; the present invention has no special requirements on the amount of the solvent added, as long as ...

Embodiment 1

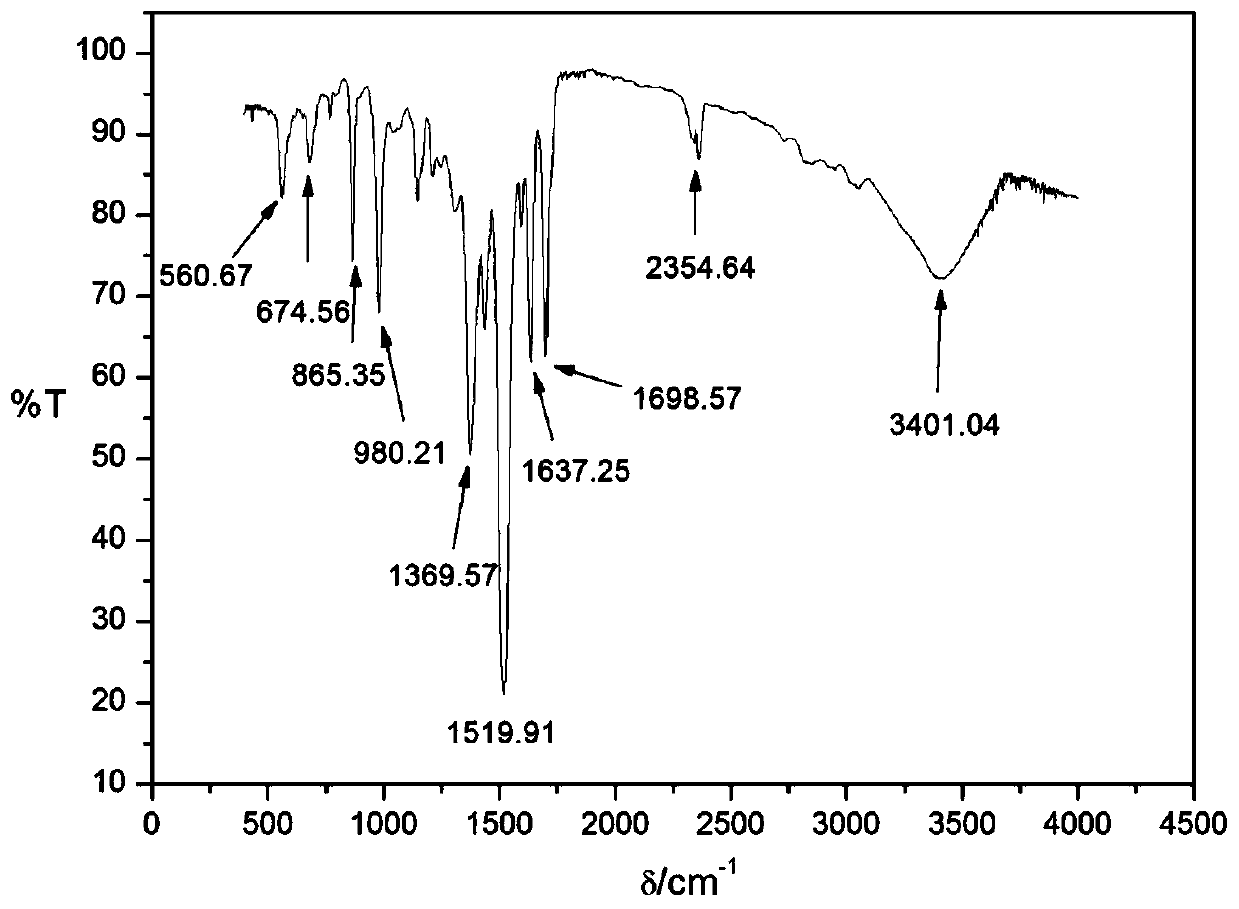

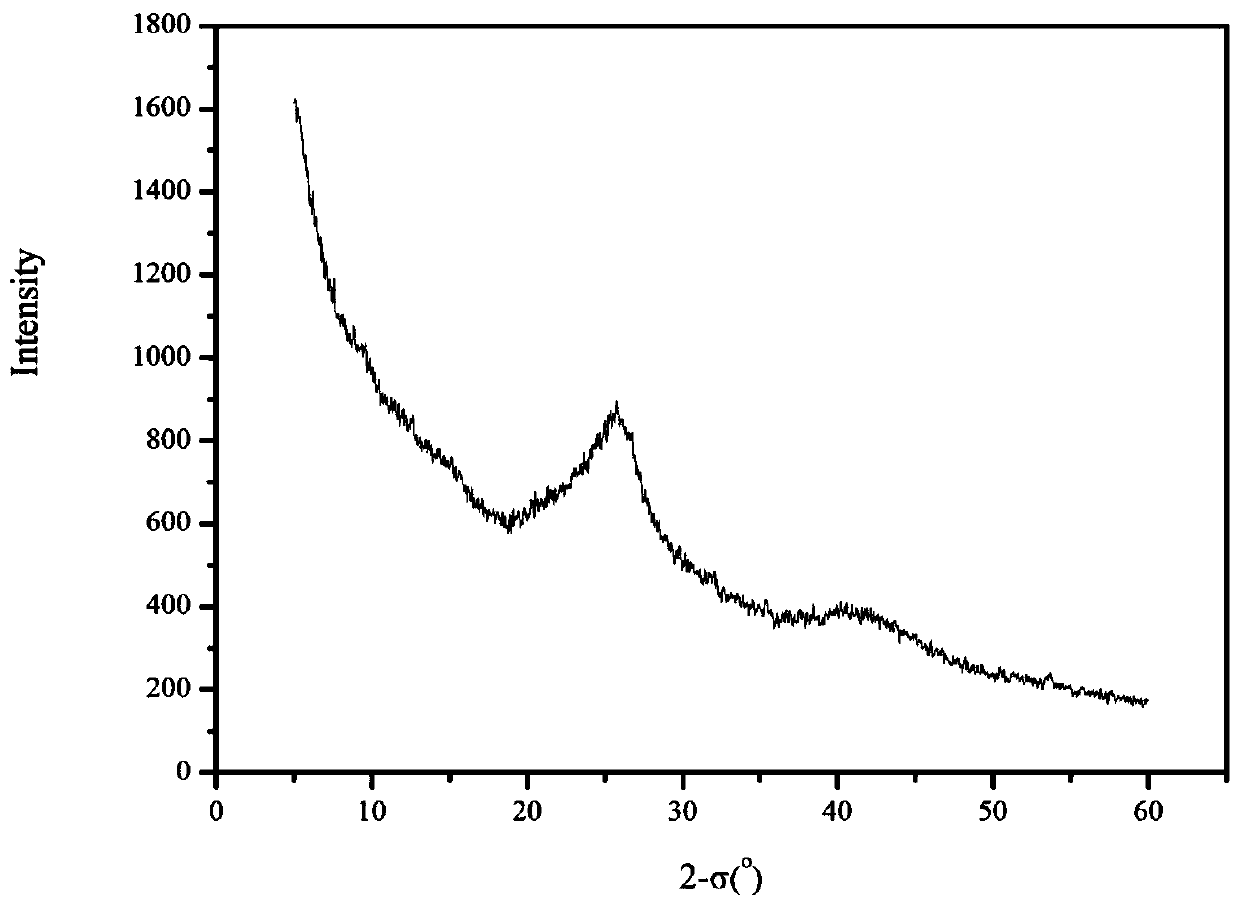

[0043] Use an electronic balance to accurately weigh 0.2065g 2,4,6-trimethyl-1,3,5-triazine, 0.2699g 1,3,5-benzenetricarbaldehyde and 0.3489g potassium hydroxide, and measure 60mL with a graduated cylinder Anhydrous methanol, put medicines and reagents into a clean and dry round-bottomed flask, put a magnet, put the flask into a constant temperature oil bath, set up an experimental device, and put a thermometer into the silicone oil. Turn on the power of the magnetic stirrer and the heating device, turn on the switch, and set the heating temperature to 70°C. After condensation and reflux, the reaction was carried out for 72 hours to obtain a light yellow liquid. Turn off the switch of the magnetic stirrer and the heating device, cool the product to room temperature and suction filter, wash with absolute ethanol 2 to 3 times, take a small amount in DMF (N,N-dimethylformamide) (if the solid is insoluble, then synthesize polymer), dried to obtain a white solid. Put the solid on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com