Process for preparing slurry of novel core layer of coated duplex board with grey back

A preparation process and a grey-white-background technology, applied in papermaking, papermaking machines, wet end of paper machines, etc., can solve the problems of high cost of pulp used for the core layer, high production cost, and impact on development, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

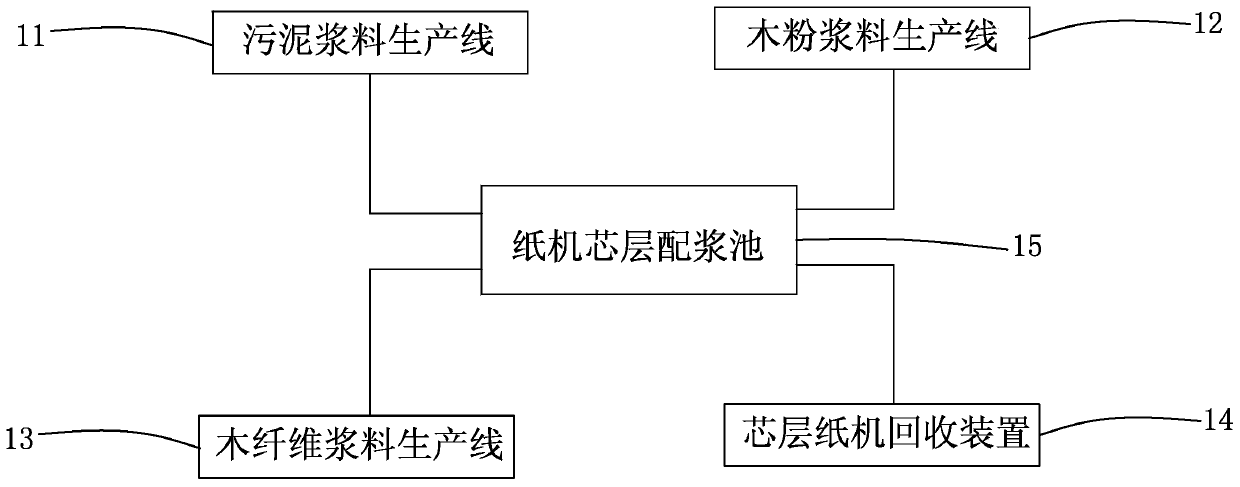

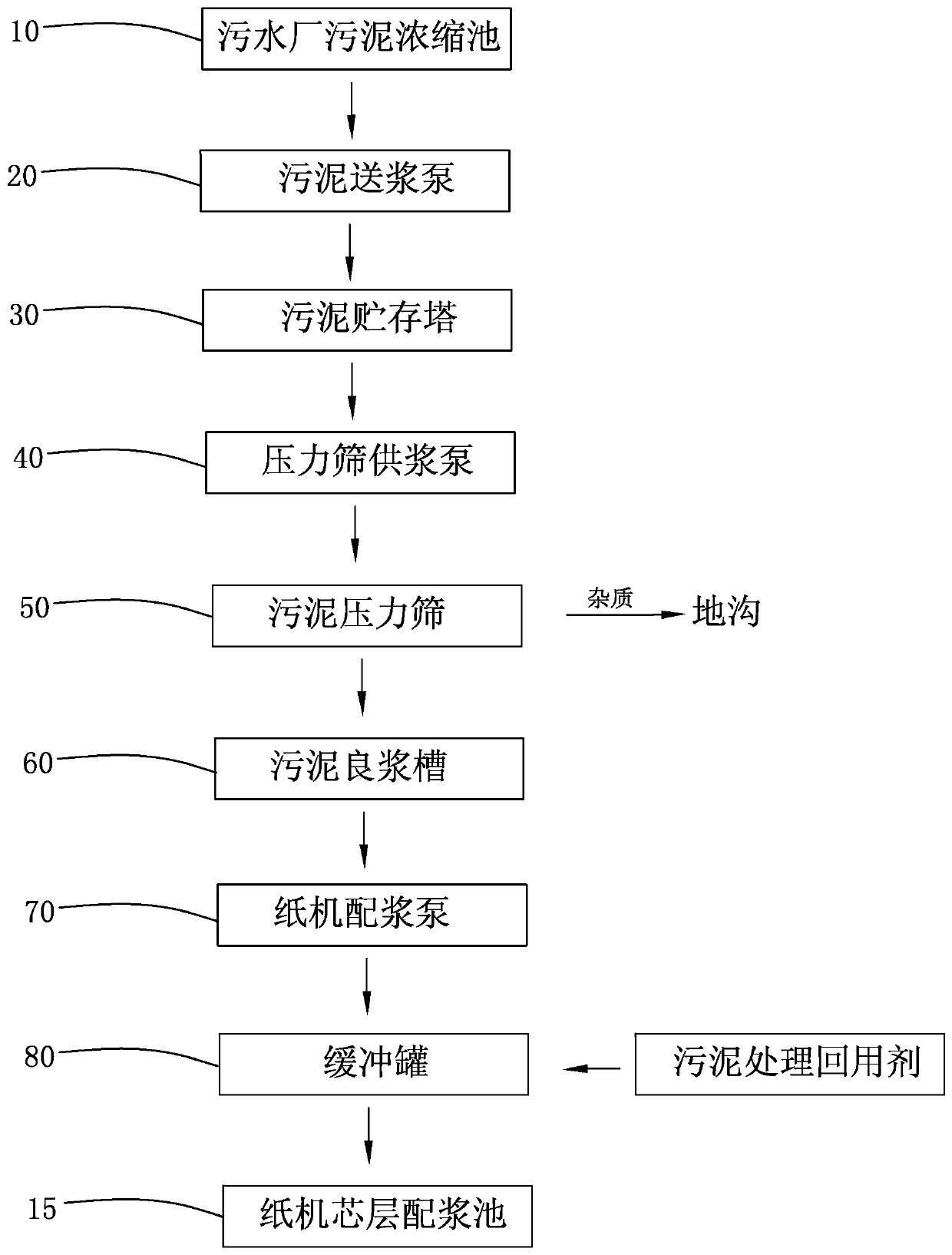

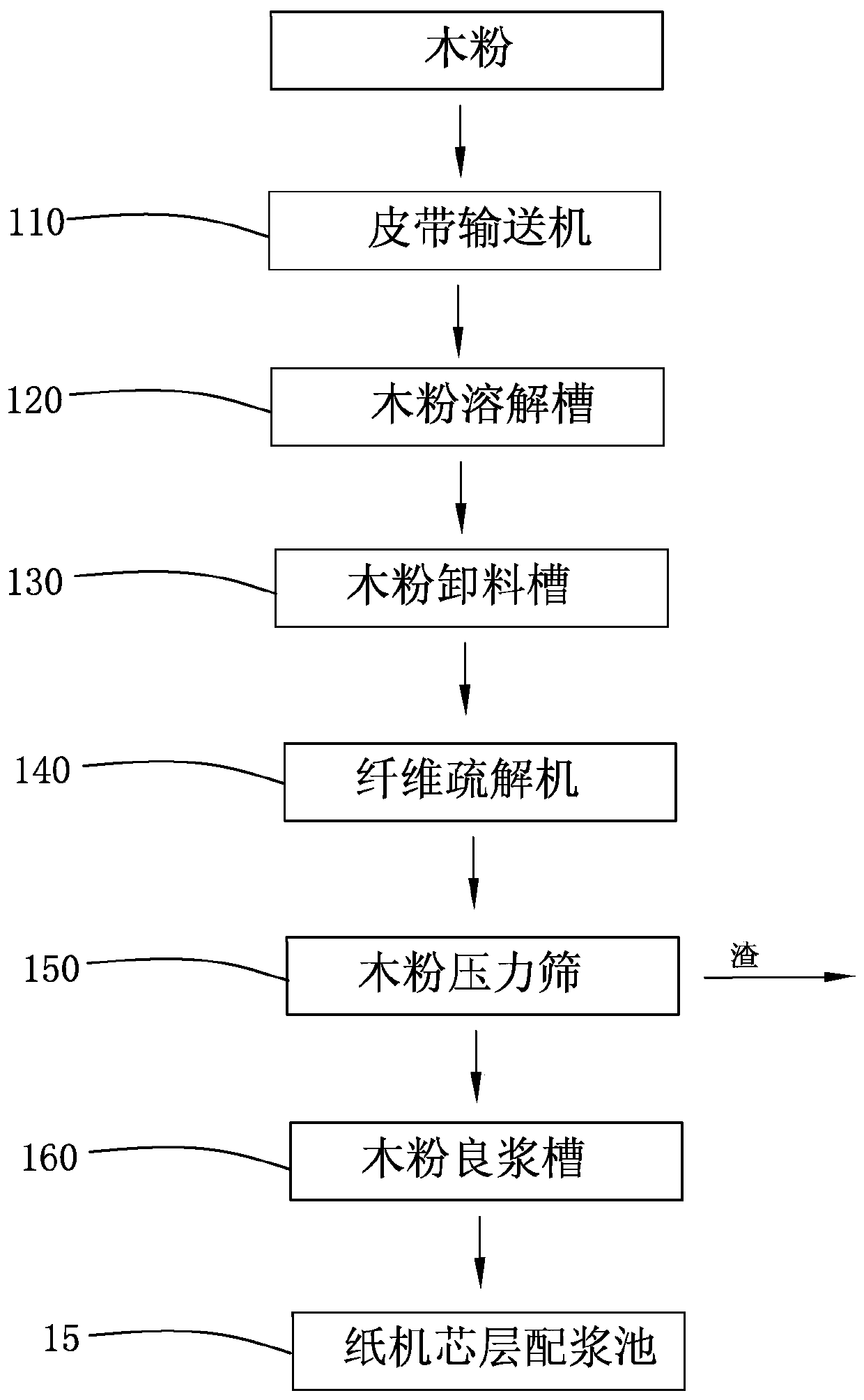

[0028] Such as Figure 1 to Figure 4 As shown, the present invention provides a novel coated gray bottom whiteboard paper core layer slurry preparation process, which is used to make coated gray bottom whiteboard paper core layer slurry, and the preparation of the novel coated gray bottom whiteboard paper core layer slurry The process includes the following steps:

[0029] A. Preparation of slurry

[0030] (1) prepare sludge slurry, provide a sludge slurry production line 11, described sludge slurry production line 11 comprises the sewage plant sludge thickening tank 10, sludge slurry delivery pump 20, sludge storage tower 30 connected successively , Pressure screen feed pump 40, sludge pressure screen 50, good sludge tank 60, paper machine pulp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com