Prepreg vacuum hot-pressing tapping temperature control system

A technology of furnace temperature and prepreg, applied in the direction of furnace control device, furnace, lamination, etc., can solve the problems of delamination or insufficient bonding force at the junction of soft and hard, and achieve the effect of stabilizing the change value of expansion and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

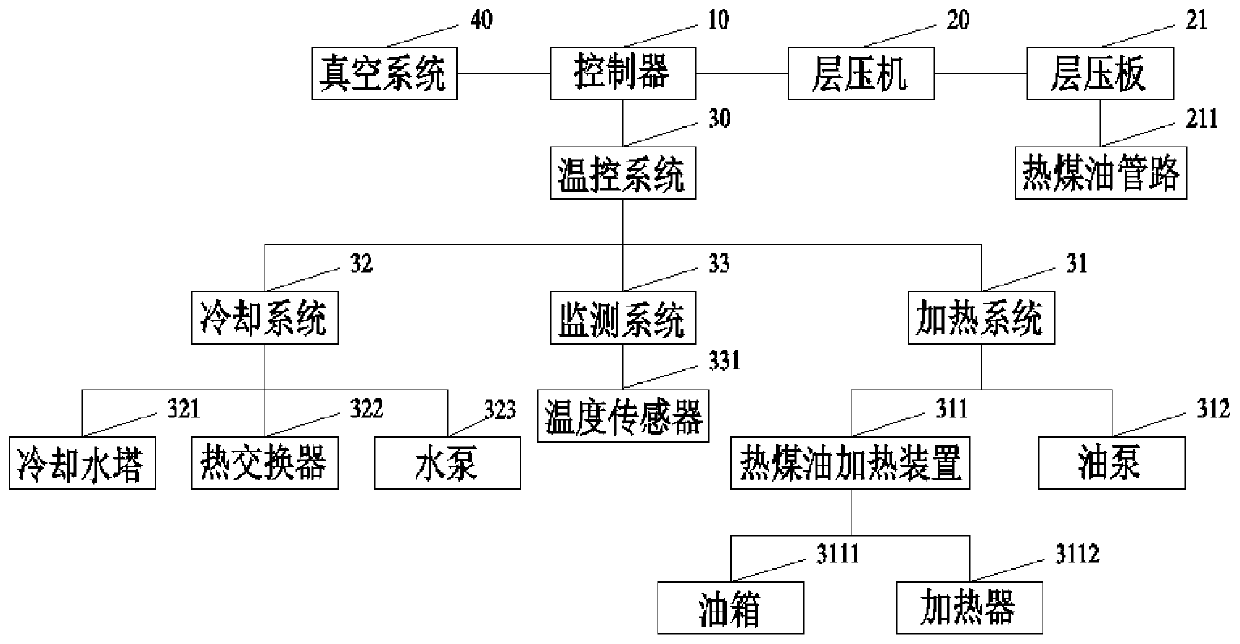

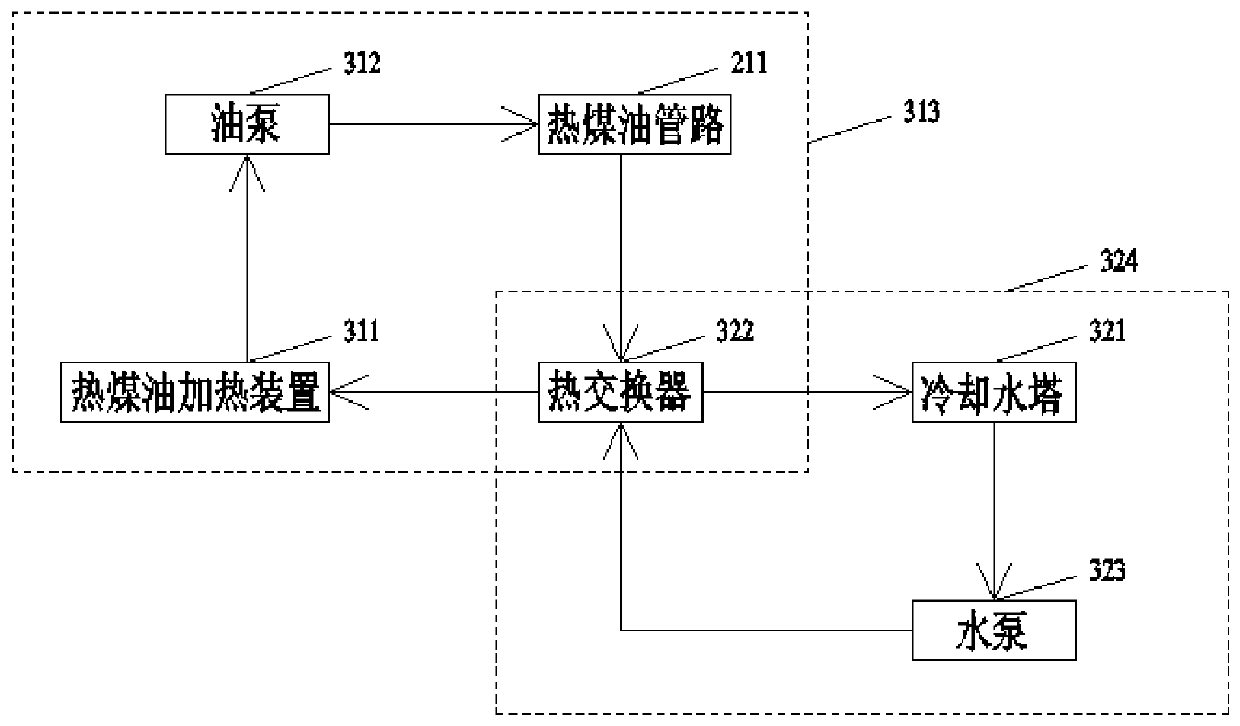

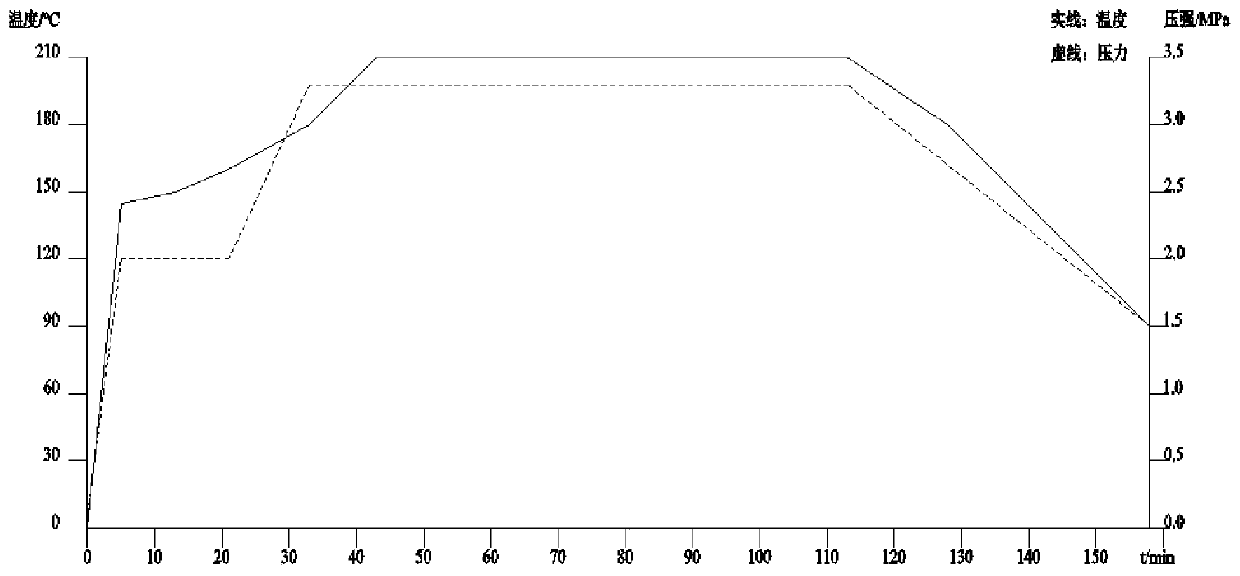

[0018] Please refer to Figure 1~3 As shown, the present invention provides a temperature control system for vacuum hot pressing of prepregs, including a controller 10, a laminator 20, a temperature control system 30 and a vacuum system 40, and a laminate 21 is arranged in the laminator 20, and the laminate 21 is provided with thermal kerosene pipeline 211; temperature control system 30 includes heating system 31, cooling system 32 and monitoring system 33; heating system 31 includes thermal kerosene heating device 311 and oil pump 312, thermal kerosene heating device 311 includes oil tank 3111 and built The heater 3112 in the fuel tank 3111; the cooling system 32 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com