Flexible pressure sensor based on hollow sphere structure, and preparation method thereof

A pressure sensor and hollow ball technology, applied in the sensor field, can solve the problems of small pressure sensor range, slow response time, low sensitivity, etc., and achieve the effects of fast response time, low cost and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

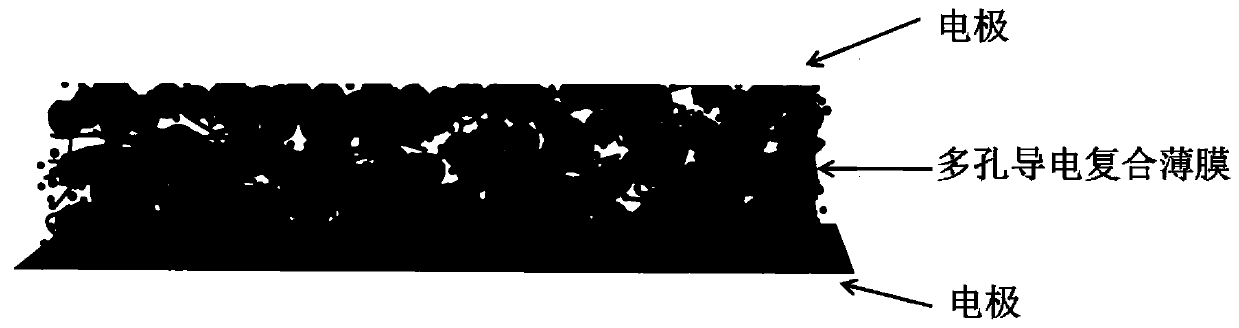

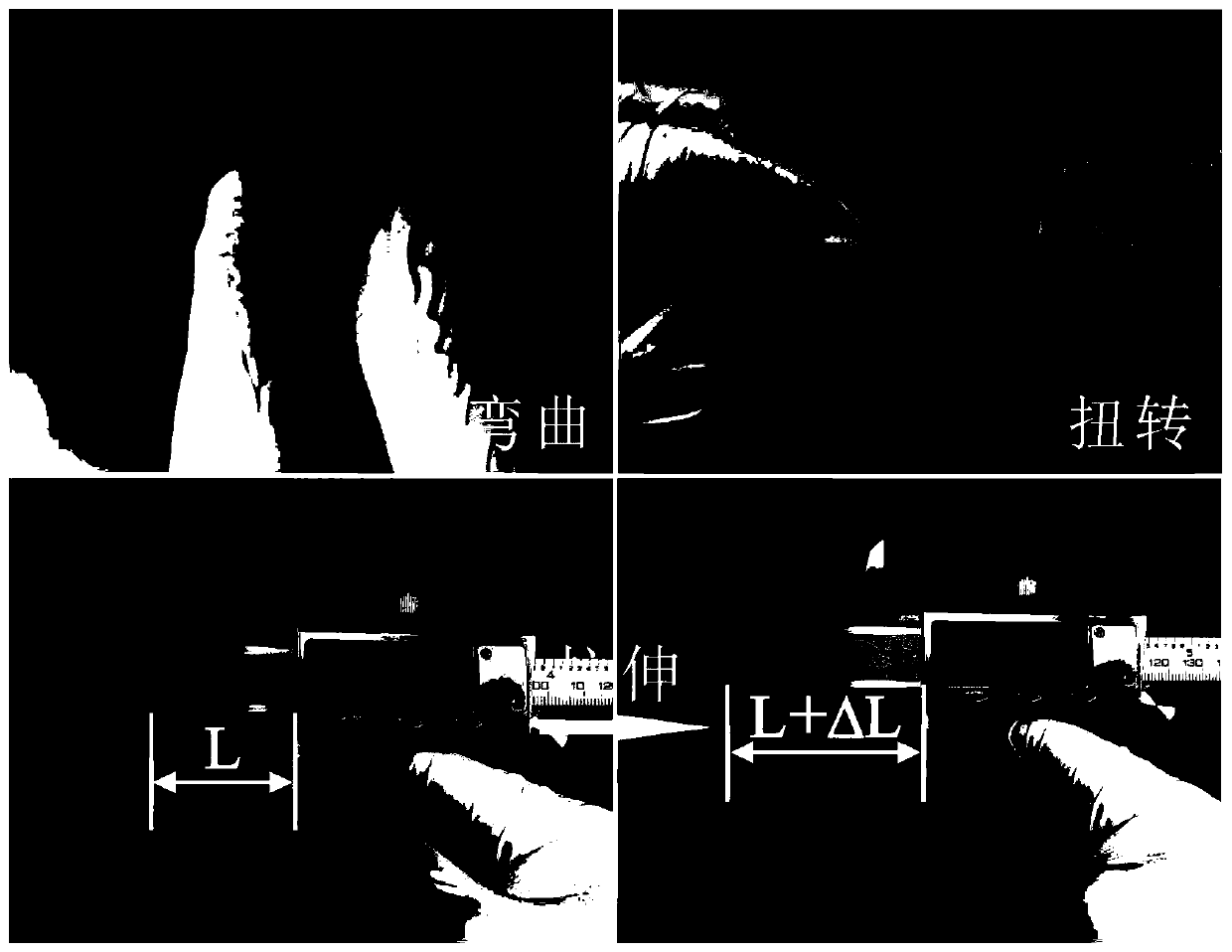

[0035] Such as figure 1 As shown, the flexible pressure sensor based on the hollow sphere structure of the present invention is a sandwich structure, with the conductive fabric as the upper and lower electrodes, and a porous conductive composite film as a pressure sensitive unit is arranged between the two electrodes;

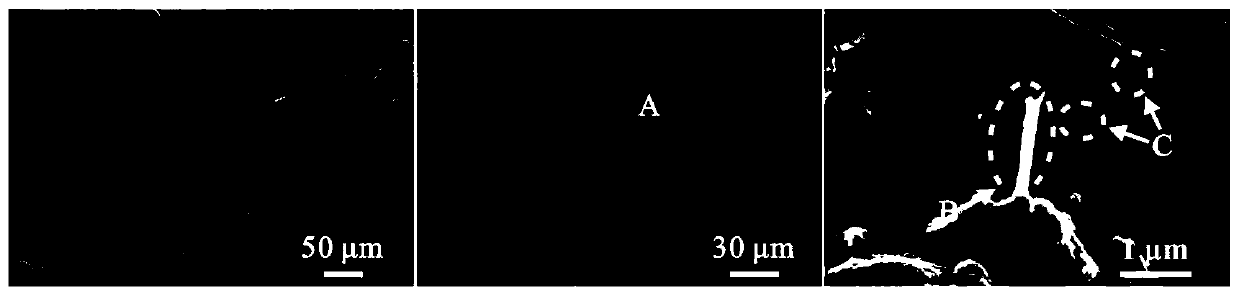

[0036] Among them, the porous conductive composite film is based on silicon rubber, heat-expandable microspheres are used as elastic elements, and carbon black and multi-walled carbon nanotubes are used as conductive materials. The mass ratio of heat-expandable microspheres, silicone rubber, multi-walled carbon nanotubes, and carbon black is 1:8:0.4:0.6, which is the optimal proportion determined through experiments: when the mass fraction of heat-expandable microspheres is 10%, , the cell density of the composite material after foaming is the best, and there are too many thermal expansion microspheres, which is not conducive to the solidification and molding o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com