A skeleton structure for the induction coil of the embedded molten steel level sensor

A technology of liquid level sensor and induction coil, which is applied in the direction of transformer/inductor coil/winding/connection, liquid level indicator, transformer/inductor cooling, etc. Unsatisfactory heat dissipation effect and other problems, to achieve the effect of strong maintenance convenience, favorable heat export, and reduced installation and replacement costs and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

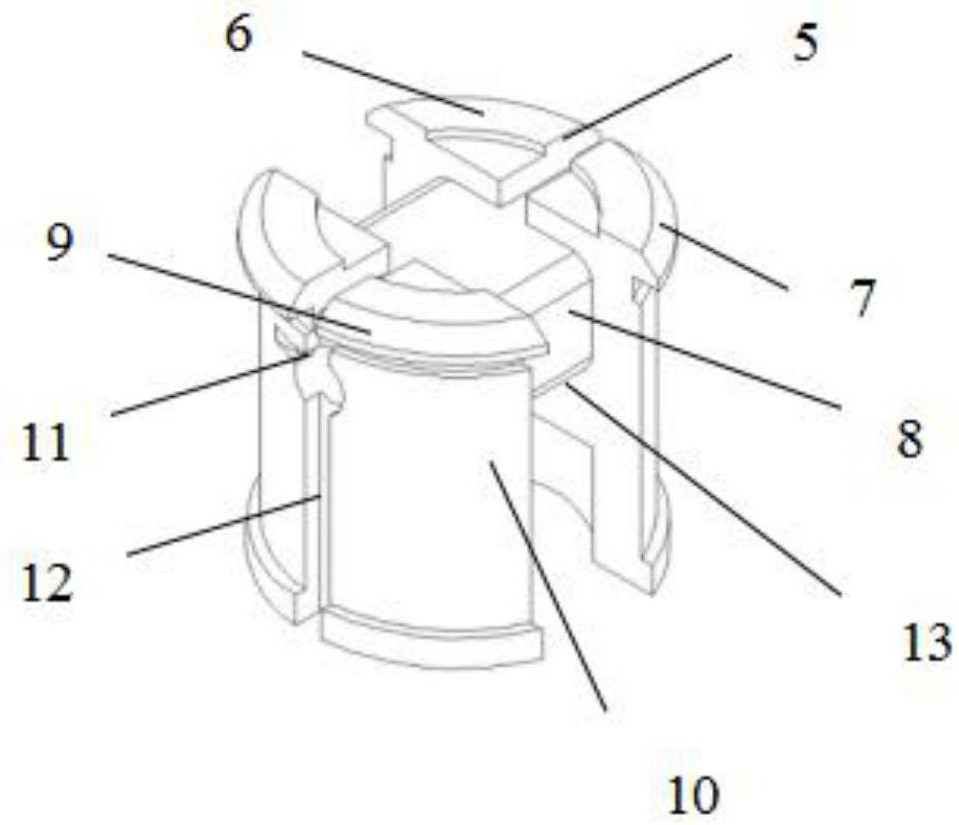

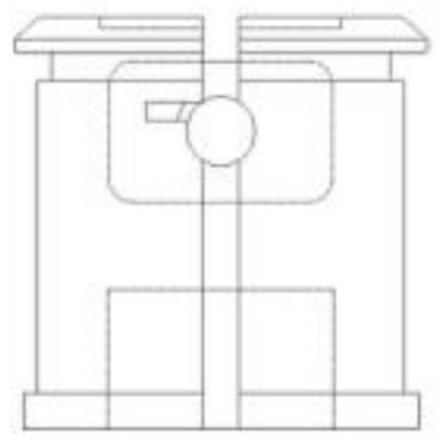

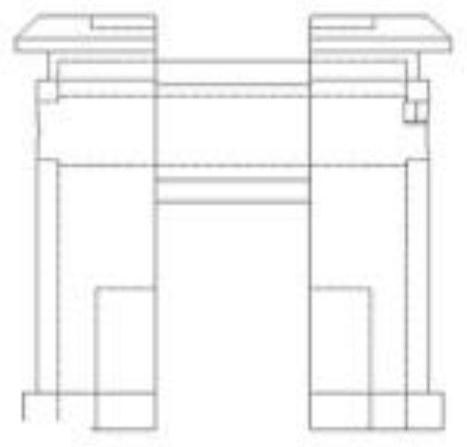

[0027] A skeleton structure for the induction coil of an embedded molten steel level sensor, comprising a cylinder surrounding wire carrier and a convex fastening plug 19 installed at one end of the cylinder surrounding wire carrier, the cylinder surrounding wire carrier and the convex fastening plug 19 The solid plug 19 is all located in the outer protective body 2 of the sensor; as Figure 1~4 As shown, the drum winding wire carrier includes a core center column 8 for winding a primary coil 16 subject to eddy current return (that is, a receiving coil), and a secondary coil 17 for winding judgment and deviation compensation capabilities The first tile-shaped body 9 of (compensation coil), and the second tile-shaped body 10 for winding the ultimate coil 18 (transmitting coil) of the electroma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com