Automatic handler and method of measuring devices using the same

A technology for automatic manipulation and manipulation of devices, applied in automated testing systems, single semiconductor device testing, semiconductor/solid-state device testing/measurement, etc., can solve problems such as judgment errors, dissatisfaction, and unqualified items as qualified items, etc., to achieve Efficiency improvement, test cost reduction, productivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] As described above, although the present invention can be applied to an automatic manipulator for not only transporting and manipulating semiconductor devices but also all types of devices including filters, oscillators, etc., the present invention will be described here as a An embodiment of a robotic manipulator for an integrated circuit typical of a semiconductor device.

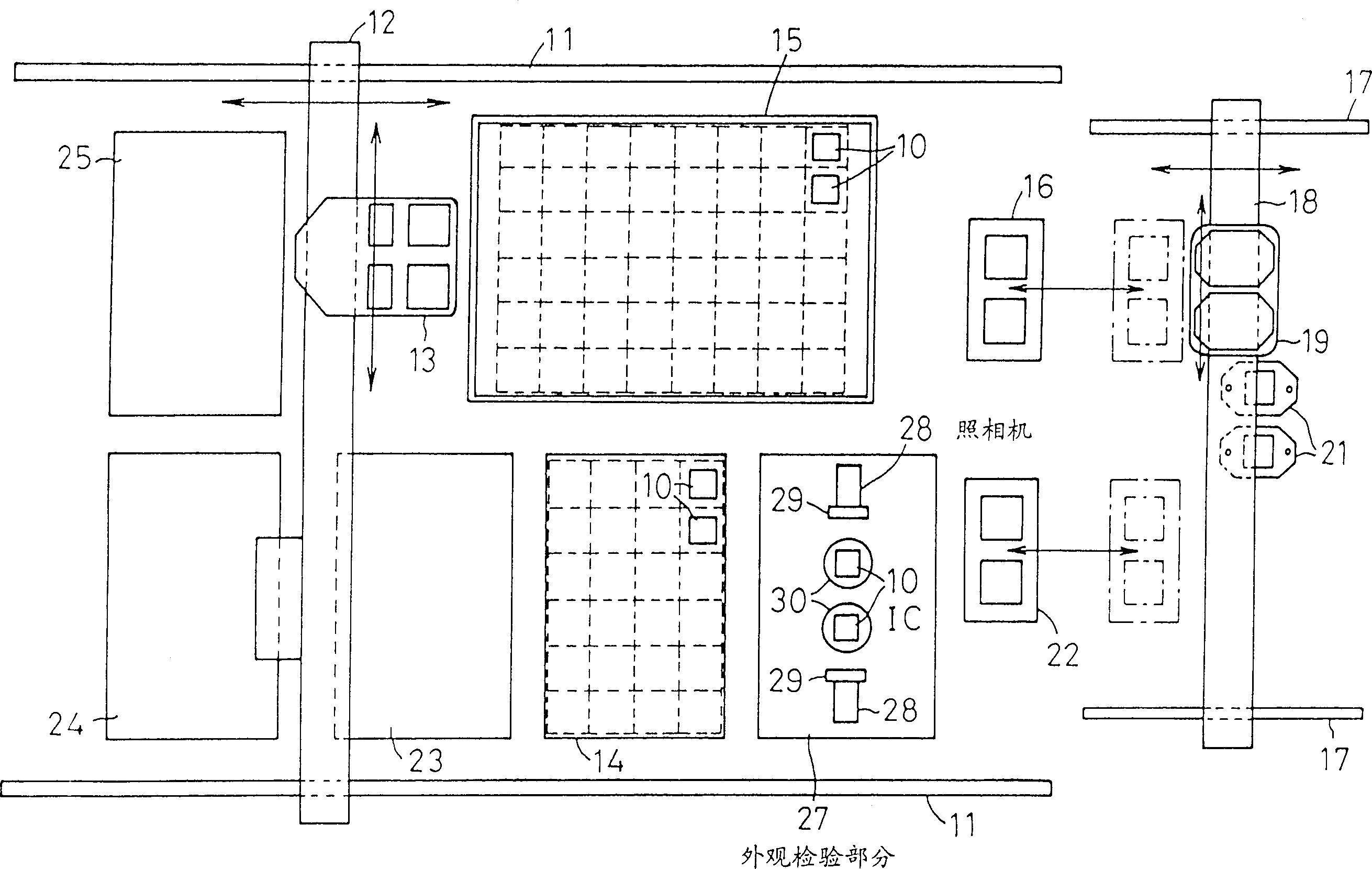

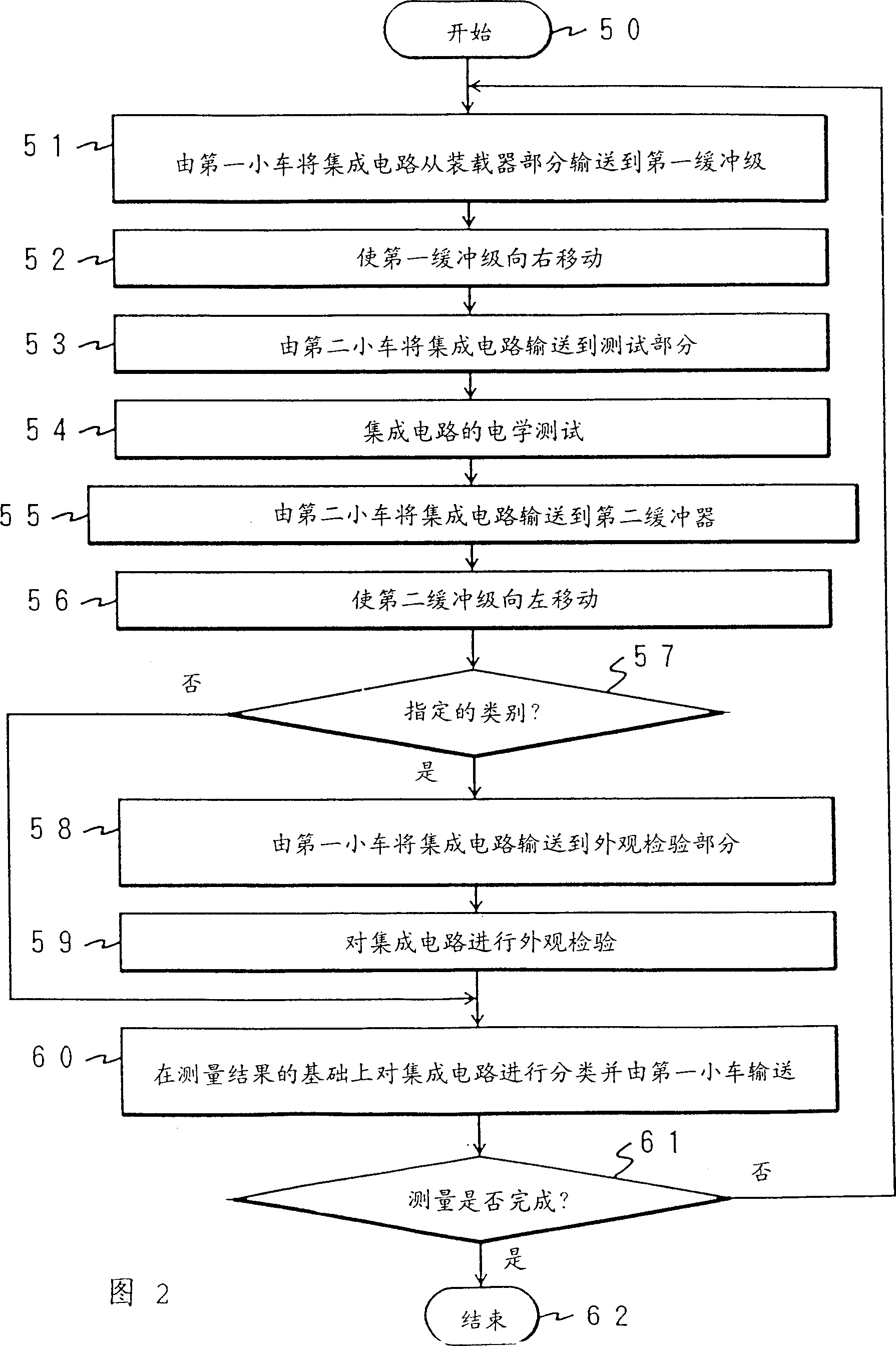

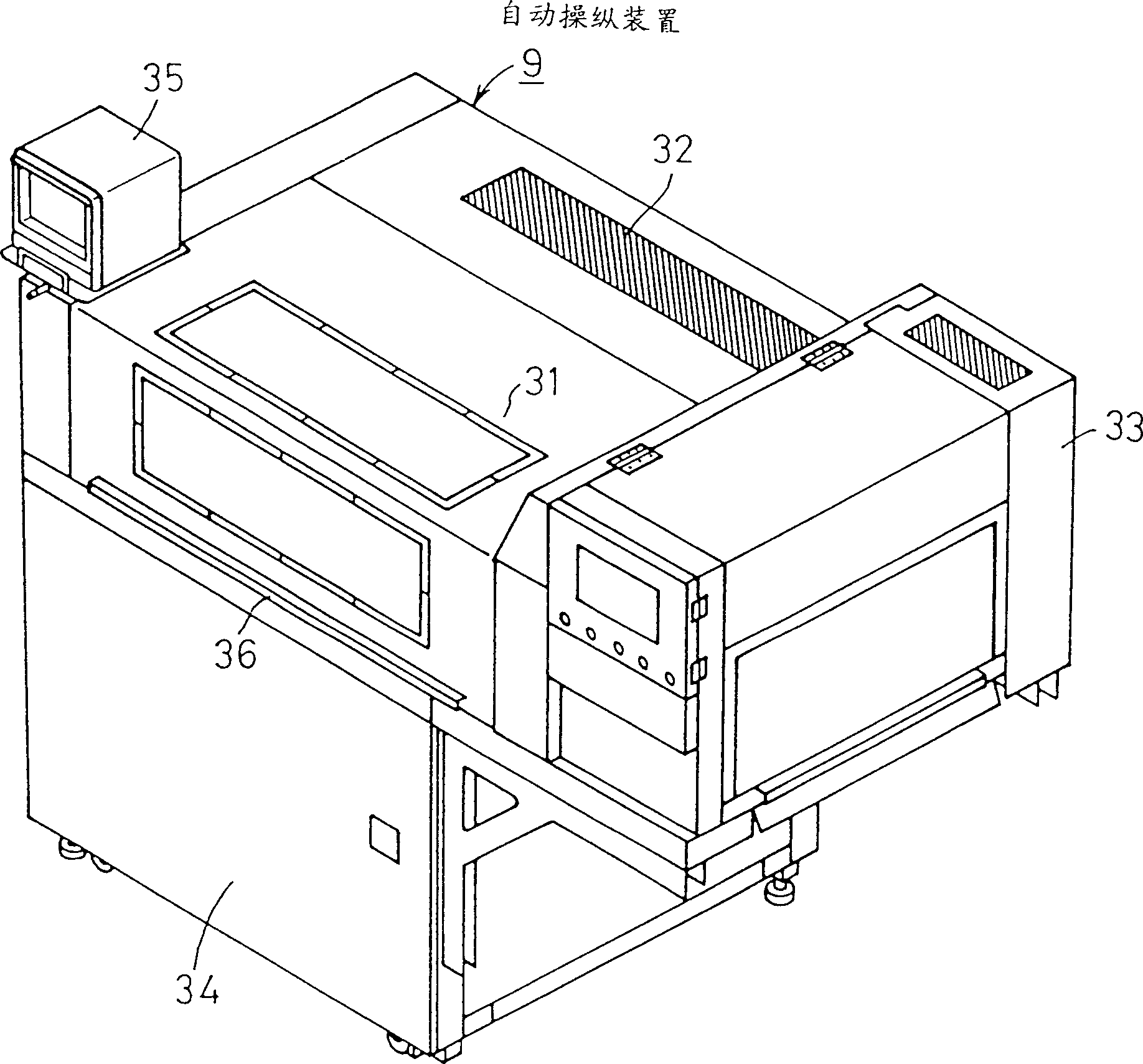

[0027] figure 1 is a schematic plan view of an embodiment of an automatic manipulator according to the present invention, and image 3 It is a schematic perspective view showing the appearance of the robot. as from figure 1 and 4 Clearly visible in the comparison between, the structure of the automatic manipulator 9 of this embodiment and Figure 4 The conventional automatic manipulator shown in is substantially the same, and the difference is that the appearance inspection part 27 is arranged at the position of the empty disc part 26 in the conventional automatic manipulator, while the empty ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com