Processing method and device for anti-hypoxic fungus substitutional tea

A processing method and a technology of a processing device, which are applied in the field of processing methods and devices for anti-anoxic fungus substitute tea, can solve problems such as unattractive taste and smell, increase added value, protect dry ingredients, and save manufacturing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

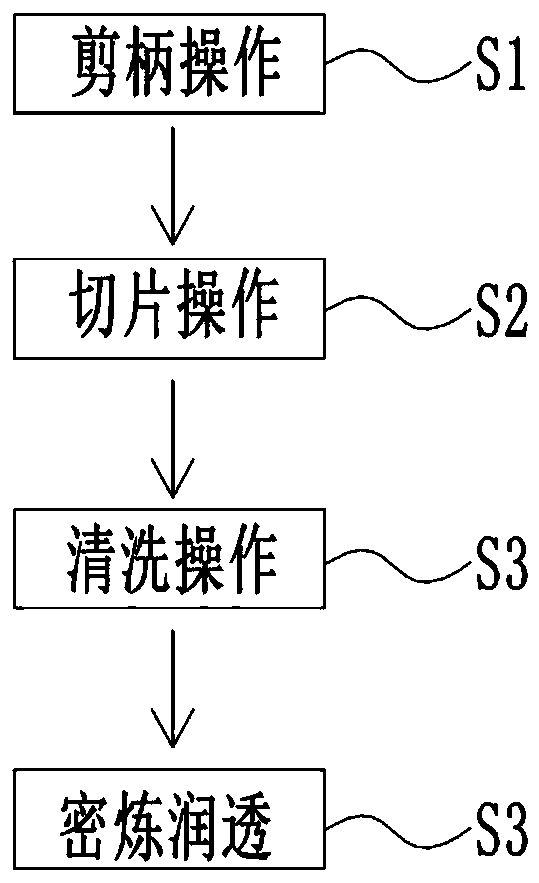

Method used

Image

Examples

Embodiment 2

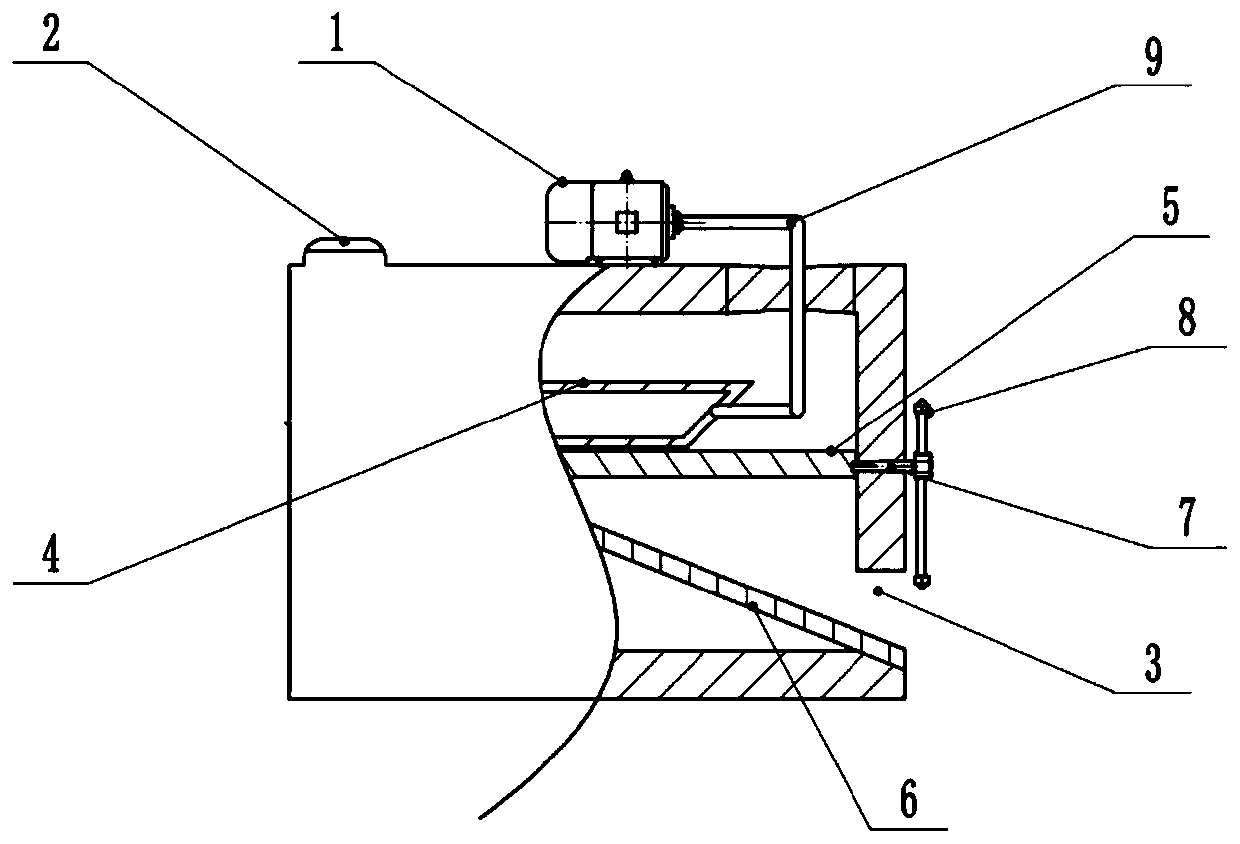

[0043] The difference between this embodiment and Embodiment 1 is that a processing device for an anoxic fungi substitute tea is added, please refer to figure 2 , this device includes a banburying run-through device and a stepper motor 1 with a model number of YS-6334-1400. The banbury run-through device includes a box body with a material inlet 2 and a material outlet 3, and the material supply along the inside of the box Direction is provided with frying plate 4, material receiving plate 5 and discharge chute 6 successively, the cross section of discharge chute 6 is a right triangle, the hypotenuse of discharge chute 6 faces material receiving plate 5, and the discharge chute 6 The channel 6 is located directly below the material receiving plate 5 , and the lowest gravitational potential energy of the discharge chute 6 is connected to the discharge port 3 .

[0044]The material receiving plate 5 is a rectangular frame with an opening. The material receiving plate 5 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com