Working device for cutting dried tomatoes into pieces and laying pieces

An operating device and technology of dried tomatoes, which are applied in the directions of loading/unloading, transportation and packaging, metal processing, etc., can solve the problems of affecting the quality of dried tomatoes, high cost, and laboriousness, and achieve low impact on quality, improve efficiency, and reduce The effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

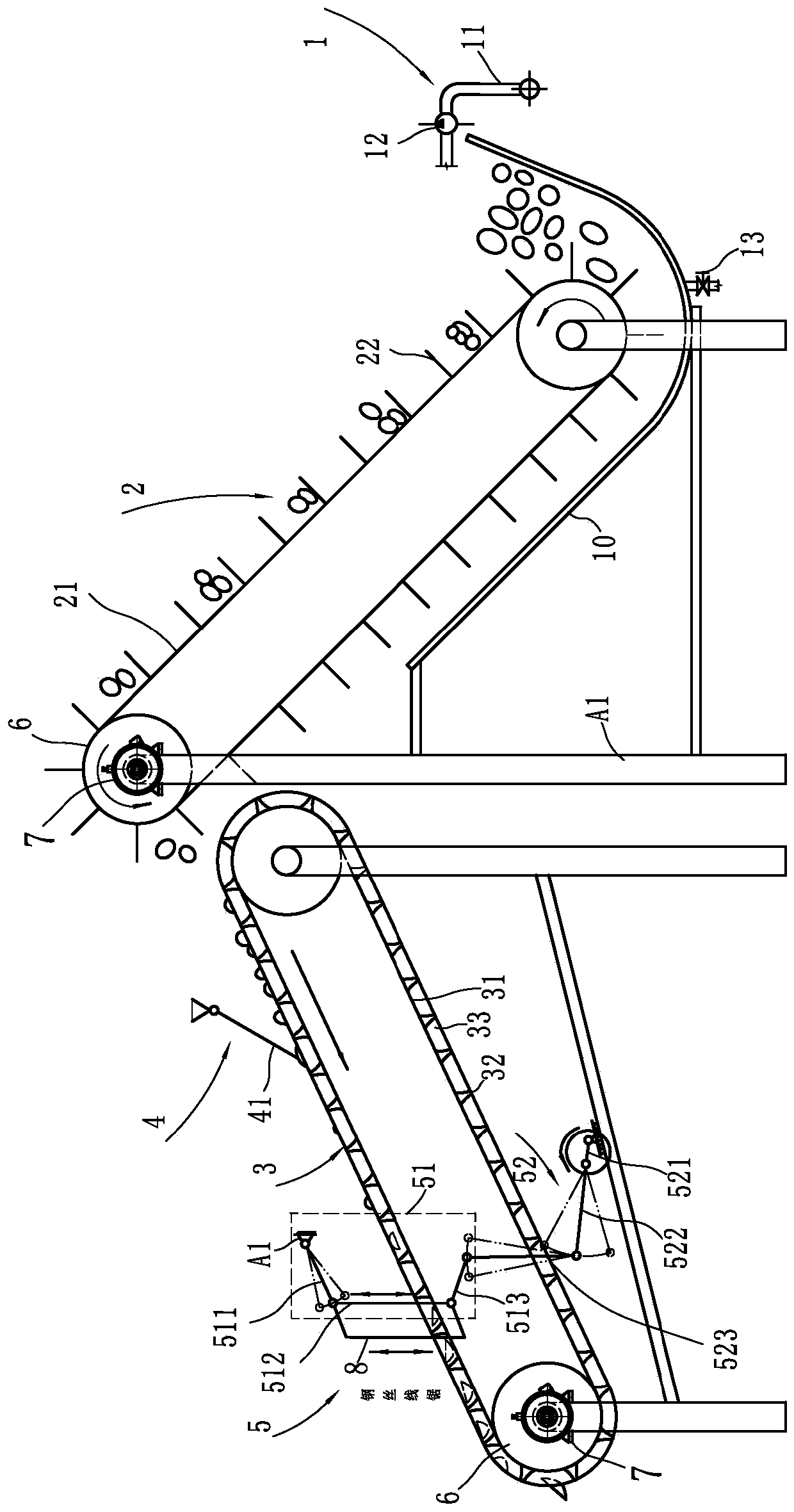

[0035] Embodiment 1: refer to Figure 1 to Figure 4

[0036] This solution provides a device for laying dried tomato slices, which is mainly composed of a frame A1, a transfer mechanism 2, a conveying mechanism 3, a paving mechanism 4 and a cutting mechanism 5;

[0037] The transfer mechanism 2 is arranged obliquely and partially submerged in the material tank 10 to form a cleaning mechanism 1. The transfer mechanism 2 is mainly composed of a power unit 7, at least two rollers 6, a conveyor chain 21 and a scraper 22. The conveyor chain 21 is arranged on at least two The conveyor body including the feeding end and the discharging end is formed on the drum 6, and the scraper 22 is a plate or row-like body standing on the conveyor chain 21 and forms a material bucket with the conveyor chain 21;

[0038] The cleaning mechanism 1 is fixedly connected with the frame A1. The cleaning mechanism 1 includes a water supply pipe 11 and a water pump 12. The water pump 12 and the water sou...

Embodiment 2

[0050] Embodiment 2: refer to Figure 1 to Figure 4

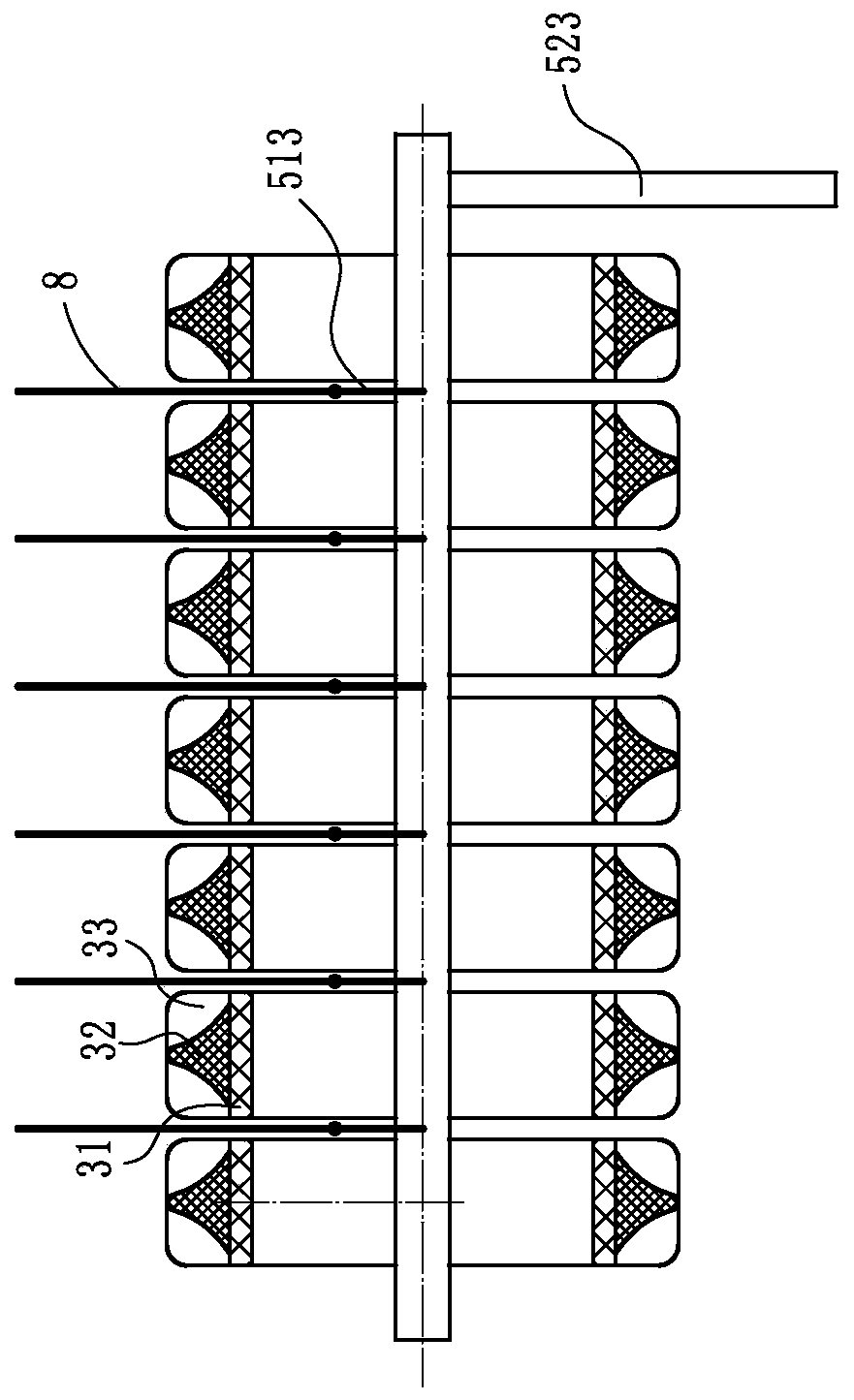

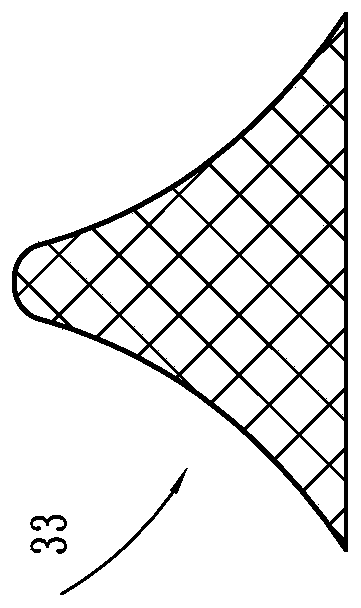

[0051] Compared with Embodiment 1, the difference is that the cutting mechanism 5 includes an eccentric wheel rocker mechanism 52, a four-bar mechanism 51 and a wire saw 8; the eccentric wheel rocker mechanism 52 includes a crank 521, a first connecting rod 522 and a second connecting rod Frame rod 511, wherein, the crank 521 and the second connecting rod 511 are hinged on the frame A1, and the two ends of the first connecting rod 522 are respectively hinged with the crank 521 and the other end of the second connecting rod 511; the four-bar mechanism 51 It includes a second connecting rod 511, a second connecting rod 512 and a third connecting rod 513, wherein the second connecting rod 511 and the third connecting rod 513 are hinged on the frame A1, and the two ends of the second connecting rod 512 They are hinged to the other ends of the second connecting rod 511 and the third connecting rod 513 respectively; the wire saw...

Embodiment 3

[0055] Embodiment 3: refer to Figure 6 and Figure 7

[0056] Compared with Embodiment 2, the difference is that the cutting mechanism 5 includes a first sprocket 5a and a second sprocket 5b, and the cutting knife is a cutting blade 5e; the first sprocket 5a is fixed on any roller shaft of the conveying mechanism 3, and the second The sprocket 5b is fixed on another roller shaft of the conveying mechanism 3 or the rotation of any position of the conveying mechanism 3 is fixed on the shaft of the frame A1, the first sprocket 5a and the second sprocket 5b are connected by a transmission belt or a transmission chain; 5e is coaxially fixed with the second sprocket 5b and placed in the gap of the conveyor belt 31.

[0057] This tomato slicer works as follows:

[0058] The power device 7 of the conveying mechanism 3 drives all the roller shafts to rotate, and the first sprocket 5a is fixed on any roller shaft of the conveying mechanism 3 so as to follow the rotation of the rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com