Emulsified asphalt, emulsified asphalt mixture and cold-mixed and cold-laid wearing course prepared from the mixture

A technology of emulsified asphalt and wear layer, which is applied to building insulation materials, building components, buildings, etc., and can solve problems such as high driving noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides the preparation method of described emulsified asphalt, comprises the following steps:

[0033] S10, under the condition of 45° C. to 65° C., mix and stir the water, the organic amine emulsifier, and the organic polybasic acid in proportion to uniformly prepare soap liquid;

[0034] S20, pass the soap liquid prepared in step S10 and the heated asphalt through a colloid mill in proportion to prepare emulsified asphalt.

[0035] The organic amine emulsifier can be selected from one or more of fatty amines, fatty amine epoxides, fatty imidazolines, fatty quaternary ammonium salts and fatty piperazine emulsifiers, so The organic polybasic acid can be selected from one or more of oxalic acid, terephthalic acid, maleic acid, tartaric acid, citric acid and trimesitic acid.

[0036]In the step S10, the soap liquid is prepared under the temperature condition of 45°C-65°C. In one embodiment, the temperature in step S10 may preferably be 55°C-...

Embodiment 1

[0060] S00, heat 1,000 parts of heavy-duty No. 70 asphalt to 180°C-190°C, add 50 parts of SBS to the asphalt, grind the mixture through a colloid mill and keep the temperature of the mixture at 180°C-190°C for 4-5 hours, then After reducing the temperature to 170°C-180°C, add 1 part of sulfur and keep it warm for 1-2 hours to obtain modified asphalt;

[0061] S10, heat 600 parts of water to 55 ℃ ~ 65 ℃, add 50 parts of organic amine emulsifier (oil diamine ethoxylate, CAS number: 68442-23-9) and 50 parts of citric acid into the water and stir Uniform preparation of soap liquid;

[0062] S20, pump the soap solution prepared in step S10 and the modified asphalt prepared in step S00 into the colloid mill, adjust the parameters of the colloid mill, and prepare emulsified asphalt.

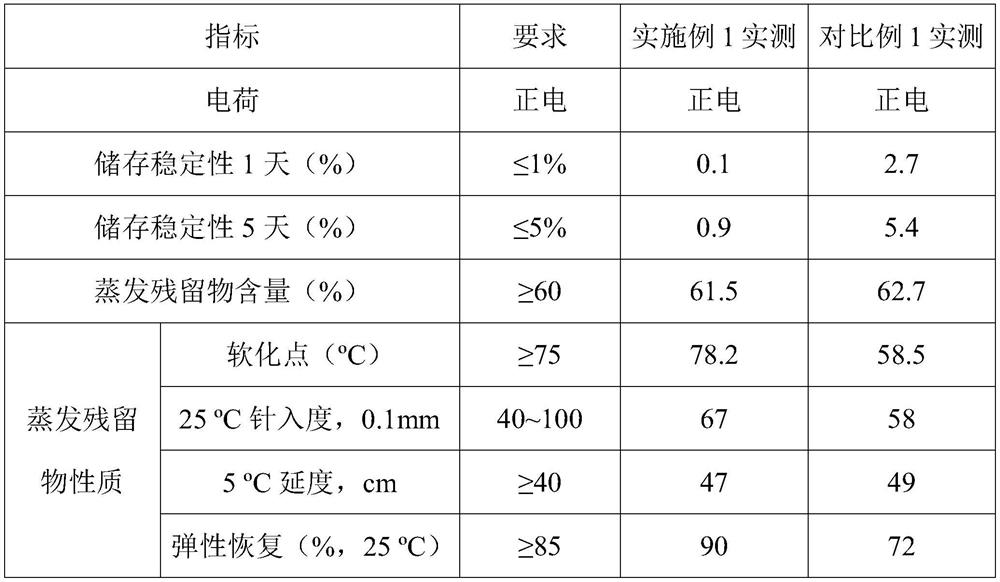

[0063] The above-mentioned prepared emulsified asphalt was tested for performance, and the various indicators of the asphalt emulsion were measured according to the national standard determination meth...

Embodiment 2

[0069] S10, heat 600 parts of water to 45-55 °C, add 50 parts of organic amine emulsifier (oil diamine ethoxylate, CAS number: 68442-23-9) and 75 parts of oxalic acid into the water and stir evenly, Then add 100 parts of styrene-butadiene emulsion, and further stir to complete the soap solution preparation;

[0070] S20, pump the soap liquid prepared in step S10 and 1000 parts of heavy Jiao No. 70 asphalt heated to 140° C. into the colloid mill, adjust the parameters of the colloid mill, and prepare emulsified asphalt.

[0071] Performance tests were carried out on the emulsified asphalt prepared above: the emulsified asphalt is cationic, the storage stability of 1 day and 5 days is 0.1% and 2.0% respectively, the evaporation residue content is 60.3%, and the mixing time with the aggregate is 150s. The initial setting time is 8 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com