Plastic mold steel plate and processing method thereof

A technology of plastic molds and processing methods, applied in metal material coating process, coating, melting spray plating and other directions, to achieve the effects of good wear resistance, high thermal conductivity and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

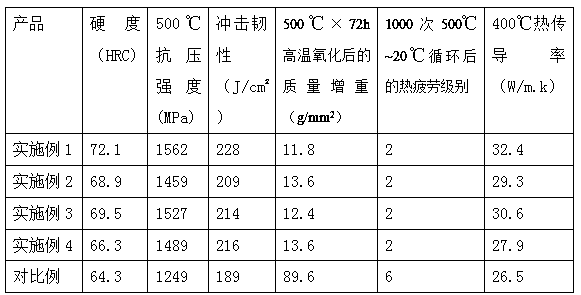

Examples

Embodiment 1

[0024] A plastic mold steel plate, the chemical composition of the mold steel plate is calculated by weight percentage: C: 0.42%; Si: 0.35%; Mn: 1.00%; Mo: 0.65%; Cr 0.42%; V: 0.65%; Bi 0.12 %; Co 0.20%; W 0.10%; Er: 0.23%; Y: 0.09%;

[0025] The processing method of described plastic mold steel plate, comprises the steps:

[0026] (1) Weigh the C, Si, Mn, Mo, Cr, V, Bi, Fe raw materials according to the above proportions, put them into the electric arc furnace for melting, after refining, pour the steel ingot under vacuum condition, and anneal the steel ingot at 830℃ after cooling. Stress treatment to obtain electrode blank;

[0027] (2) Place the electrode blank in electroslag remelting and place it in an electroslag remelting furnace under the protection of an inert gas for electroslag remelting treatment to obtain an electroslag ingot; then anneal the electroslag ingot at 830°C;

[0028] (3) Put the electroslag ingot into a high-frequency induction melting furnace, heat ...

Embodiment 2

[0032] A plastic mold steel plate, the chemical composition of the mold steel plate is calculated by weight percentage: C: 0.38%; Si: 0.46%; Mn: 1.18%; Mo: 0.58%; Cr 0.38%; V: 0.55%; Bi 0.08 %; Co 0.16%; W 0.12%; Er: 0.15%; Y: 0.13%;

[0033] The processing method of described plastic mold steel plate, comprises the steps:

[0034] (1) Weigh the C, Si, Mn, Mo, Cr, V, Bi, Fe raw materials according to the above proportions, put them into the electric arc furnace for melting, after refining, pour the steel ingot under vacuum condition, and anneal the steel ingot at 850°C after cooling. Stress treatment to obtain electrode blank;

[0035] (2) Place the electrode blank in electroslag remelting and place it in an electroslag remelting furnace under the protection of an inert gas for electroslag remelting treatment to obtain an electroslag ingot; then anneal the electroslag ingot at 850°C;

[0036] (3) Put the electroslag ingot into a high-frequency induction melting furnace, heat...

Embodiment 3

[0040] A plastic mold steel plate, the chemical composition of the mold steel plate is calculated by weight percentage: C: 0.45%; Si: 0.38%; Mn: 0.8%; Mo: 0.65%; Cr 0.42%; V: 0.65%; Bi 0.12%; Co 0.24%; W 0.08%; Er: 0.22%; Y: 0.08%;

[0041] The processing method of described plastic mold steel plate, comprises the steps:

[0042] (1) Weigh the C, Si, Mn, Mo, Cr, V, Bi, Fe raw materials according to the above proportions, put them into the electric arc furnace for melting, after refining, pour the steel ingot under vacuum condition, and anneal the steel ingot at 850°C after cooling. Stress treatment to obtain electrode blank;

[0043] (2) Place the electrode blank in electroslag remelting and place it in an electroslag remelting furnace under the protection of an inert gas for electroslag remelting treatment to obtain an electroslag ingot; then anneal the electroslag ingot at 850°C;

[0044] (3) Put the electroslag ingot into a high-frequency induction melting furnace, heat it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com