Preparation method for corrosion-resistant and high-conduction-characteristic magnesium alloy

A magnesium alloy, high conductivity technology, applied in the direction of metal material coating process, etc., can solve the problems of large pollution of plating solution, unfavorable environmental protection, high cost, etc., and achieve the effect of low cost, convenient waste liquid treatment and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

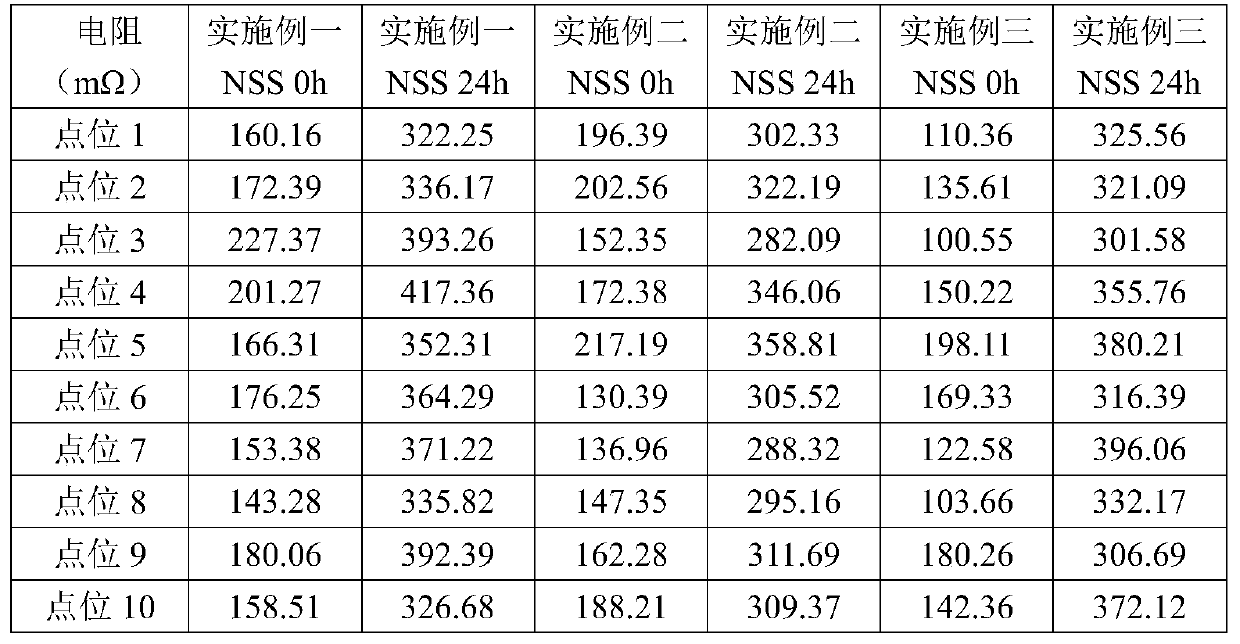

Embodiment 1

[0029] This embodiment discloses a method for preparing a magnesium alloy with corrosion resistance and high electrical conductivity. The method is mainly to perform conductive protection treatment and corrosion resistance treatment on magnesium alloy workpieces, while eliminating ESD and EMI hazards, reducing and prolonging the magnesium alloy. Long service life and enhance the safety of use, broaden the scope of application of magnesium alloys.

[0030] The preparation method includes the following steps S1-S5, wherein the magnesium alloy workpiece is AZ91D model, the size is 60mm×20mm×0.5mm, specifically:

[0031] S1. Pretreatment of the surface of the magnesium alloy workpiece, including sequential grinding, ultrasonic cleaning, and degreasing and degreasing treatment, so that the surface of the magnesium alloy workpiece is bright and clean without oil stains and stains;

[0032] S2. Pickling the magnesium alloy workpiece after step S1, and then washing with water;

[003...

Embodiment 2

[0046]This embodiment discloses a method for preparing a magnesium alloy with corrosion resistance and high electrical conductivity. The method is mainly to perform conductive protection treatment and corrosion resistance treatment on magnesium alloy workpieces, while eliminating ESD and EMI hazards, reducing and prolonging the magnesium alloy. Long service life and enhance the safety of use, broaden the scope of application of magnesium alloys.

[0047] The preparation method includes the following steps S1-S5, wherein the magnesium alloy workpiece is AZ91D model, the size is 60mm×20mm×0.5mm, specifically:

[0048] S1. Pretreatment of the surface of the magnesium alloy workpiece, including sequential grinding, ultrasonic cleaning, and degreasing and degreasing treatment, so that the surface of the magnesium alloy workpiece is bright and clean without oil stains and stains;

[0049] S2. Pickling the magnesium alloy workpiece after step S1, and then washing with water;

[0050...

Embodiment 3

[0063] This embodiment discloses a method for preparing a magnesium alloy with corrosion resistance and high electrical conductivity. The method is mainly to perform conductive protection treatment and corrosion resistance treatment on magnesium alloy workpieces, while eliminating ESD and EMI hazards, reducing and prolonging the magnesium alloy. Long service life and enhance the safety of use, broaden the scope of application of magnesium alloys.

[0064] The preparation method includes the following steps S1-S5, wherein the magnesium alloy workpiece is AZ91D model, the size is 60mm×20mm×0.5mm, specifically:

[0065] S1. Pretreatment of the surface of the magnesium alloy workpiece, including sequential grinding, ultrasonic cleaning, and degreasing and degreasing treatment, so that the surface of the magnesium alloy workpiece is bright and clean without oil stains and stains;

[0066] S2. Pickling the magnesium alloy workpiece after step S1, and then washing with water;

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com