Storage battery internal resistance measuring circuit and measuring method

A technology for measuring circuits and batteries, applied in the direction of measuring electrical variables, measuring electricity, measuring resistance/reactance/impedance, etc., can solve problems such as poor repeatability, interference of relay protection equipment, and difficulty, and improve measurement resolution and accuracy. degree, the hardware circuit structure is simple, and the AC discharge current is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

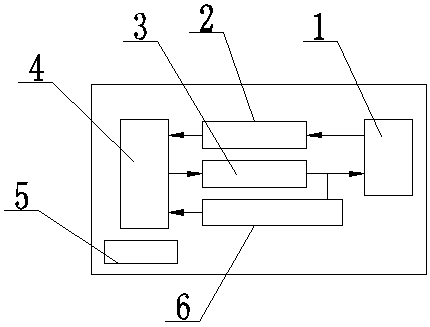

[0072] A storage battery internal resistance measurement circuit, which consists of: an MCU circuit 4 and a battery under test 1, and a voltage acquisition circuit 2, a current acquisition circuit 6 and an intelligent load circuit are connected between the MCU circuit and the battery under test 3. The smart load circuit is electrically connected to the current acquisition circuit;

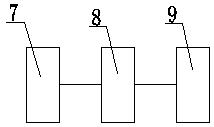

[0073] Described voltage acquisition circuit comprises digital / analog converter 7, instrumentation amplifier 8 and bandpass filter 9, and described digital / analog converter is electrically connected with described instrumentation amplifier, and described instrumentation amplifier is connected with described instrumentation amplifier The bandpass filter is electrically connected;

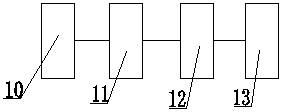

[0074] Described intelligent load circuit comprises serial interface 10, analog / digital converter 11, output converter 12 and sampling resistor 13, described serial interface, described analog / digital converter, described...

Embodiment 2

[0080] According to the storage battery internal resistance measurement circuit described in Embodiment 1, the MCU circuit adopts STM32F303CBT6 as the main control chip.

Embodiment 3

[0082] According to the battery internal resistance measuring circuit described in embodiment 1 or 2, the battery to be tested is a 2V or 12V battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com