Polyamide composition which is dyed in black, production and use thereof

A polyamide composition, the technology of the composition, applied in the direction of complex metal compounds, organic dyes, azo dyes, etc. of azo dyes, can solve the details, health hazards, black is not provided with surface quality and flow properties of composite materials particularly strong issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0158] The preparation of the polyamide molding compositions is effected by methods known per se. This involves mixing the components in proper weight ratios. The components are preferably mixed at elevated temperature by combining, mixing, kneading, extrusion or rolling. The mixing temperature is preferably from 220°C to 340°C, especially from 240 to 320°C, especially from 250 to 300°C. Suitable methods are known to those skilled in the art.

[0159] moldings

[0160] Furthermore, the invention provides moldings produced using copolyamides and corresponding polyamide molding compositions according to the invention.

[0161] The black polyamides can be used to prepare moldings by any desired suitable processing method. Suitable processing methods are in particular injection moulding, extrusion, coextrusion, thermoforming and any other known plastic forming methods. These and other examples can be found in, for example, " von Kunststoffen” [Coloration of plastics], VDI-V...

Embodiment

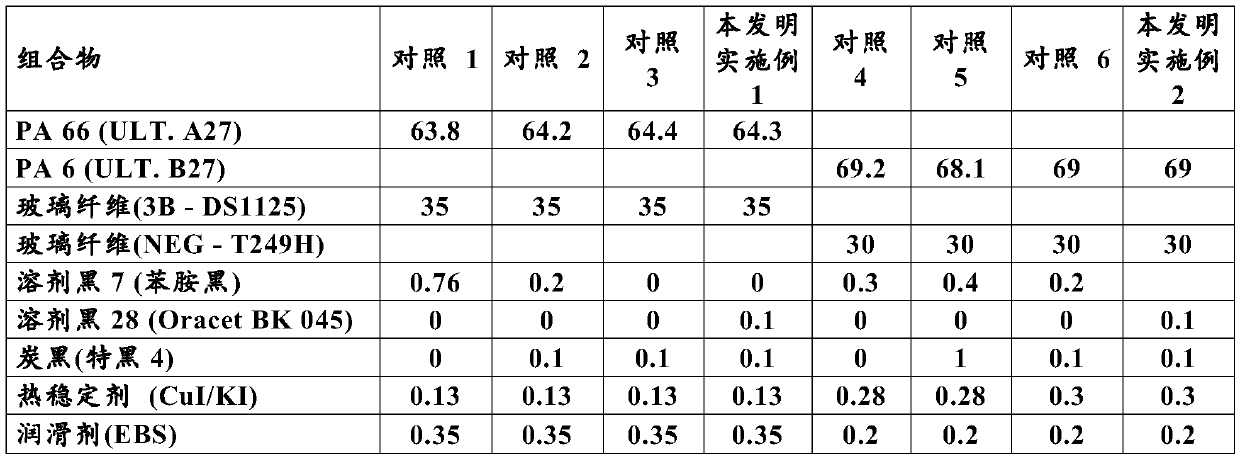

[0173] Use the following raw materials:

[0174] Nylon-6,6: A27, purchased from BASF SE, melting point: 264 ° C, viscosity value (0.5% in 96% H 2 SO 4 Medium): 150cm 3 / g

[0175] Nylon-6: B27, purchased from BASF SE, melting point: 222°C, viscosity value (0.5% in 96%H 2 SO 4 Medium): 150cm 3 / g

[0176] Glass fiber: 3B-DS1125, manufacturer: 3B-FIBREGLASS S.P.R.L., average diameter: 10.5μm, length: 4mm

[0177] Glass fiber: NEG-T249H, manufacturer: NIPPON ELECTRIC GLASS (MALAYSIA) SDN.BHD., average diameter: 10.5μm, length: 3mm

[0178] Aniline Black / Solvent Black 7: Manufacturer: COLLLOIDS LTD.

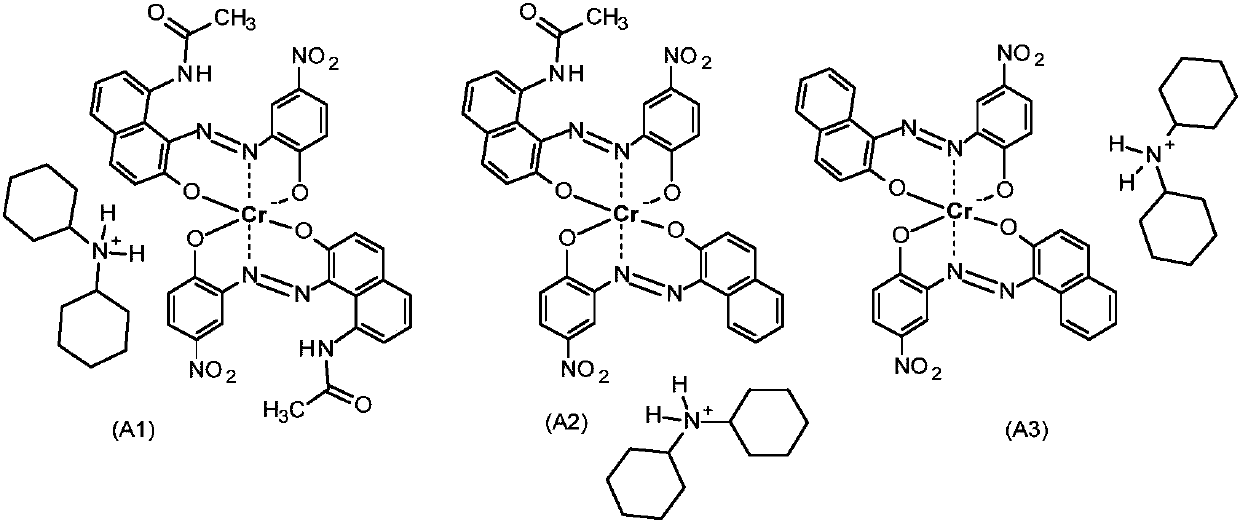

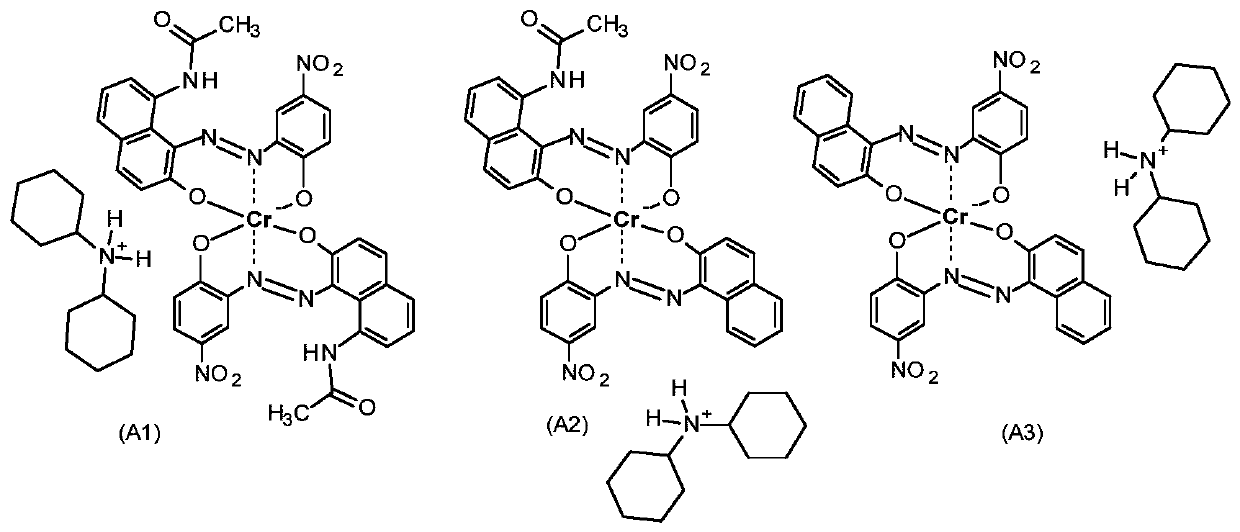

[0179] Solvent Black 28: Oracet BK 045, manufacturer: BASF SE

[0180] Carbon black (extra black 4): Manufacturer: Orion Engineered Carbons GmbH

[0181] Heat stabilizer: CuI / KI, molar ratio 1:4

[0182] Lubricant: EBS, manufacturer: Lonza Cologne GmbH

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com