Device and method for cooling and dust removal of exhaust gas from marine diesel engine

A marine diesel engine and dedusting device technology, applied in the direction of separation methods, combined devices, chemical instruments and methods, etc., can solve the problems of high smoke and dust content, complex equipment, high cost, etc., and achieve small waste and solid discharge, strong scouring and self-cleaning Action, efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

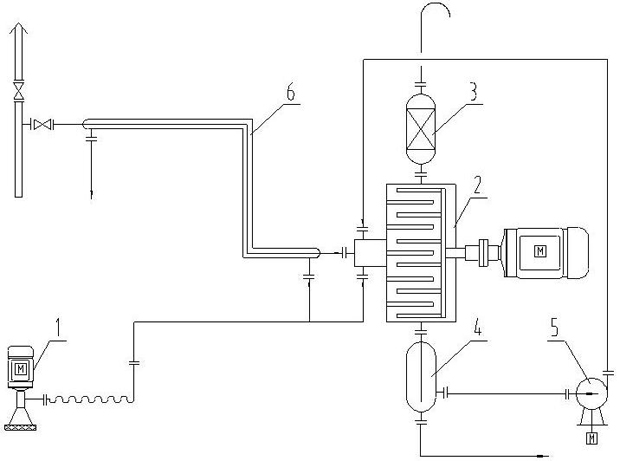

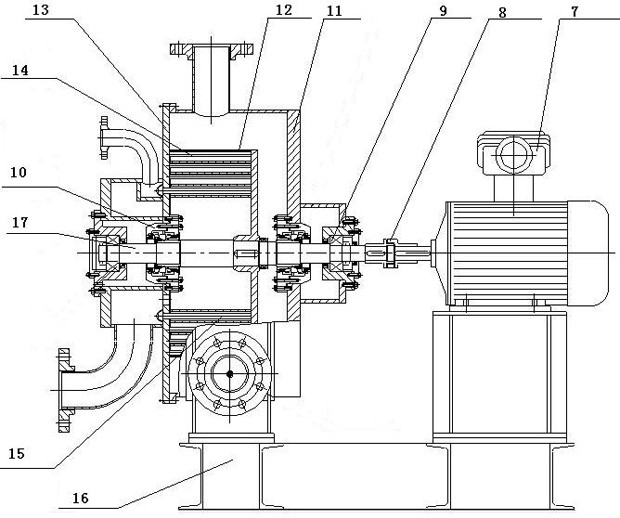

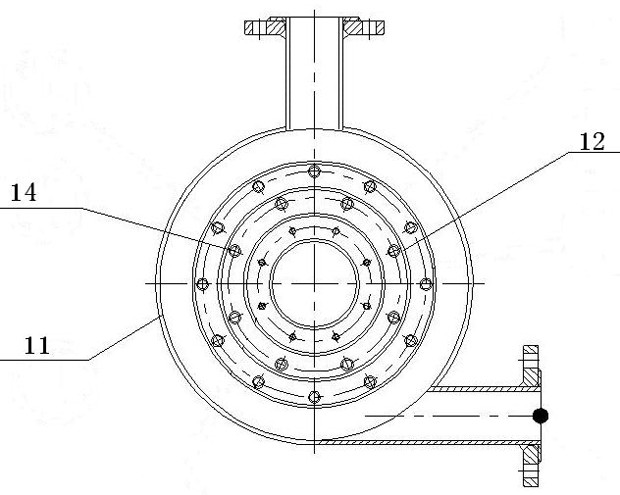

[0033] as attached figure 1 As shown, a marine diesel engine exhaust cooling and dedusting device, the marine diesel exhaust cooling and dedusting device is composed of a submersible pump 1, a rotating bed dust collector 2, an adsorption tank 3, an oil-water separation tank 4, a circulating water pump 5 and a cooling jacket 6, The submersible pump 1 is installed on one side of the hull, the suction port of the submersible pump 1 is provided with a filter, and the submersible pump 1 is connected with the rotating bed dust collector 2 and the cooling jacket 6 by a telescopic hose and a fixed flange; The rotating bed dust collector 2 is installed on the side of the chimney of the oil production machine, such as figure 2 , 3As shown, the rotating bed dust collector 2 consists of a motor 7, a coupling 8, a bearing 9, a mechanical seal ring 10, a casing 11, a rotor 12, an end cover 13, a static ring 14, a feeding nozzle 15, a frame 16. The rotating shaft 17 is composed, the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com