Test rack system for four-wheel-drive bridge assembly

A test bench and drive system technology, which is applied in vehicle testing, machine/structural component testing, measuring devices, etc., can solve the problem of free distribution of power between the front and rear axles of the four-wheel drive system, and the free distribution of power between the left and right wheels cannot be completed. It does not apply to problems such as four-wheel drive vehicle testing, so as to reduce the purchase cost and save the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

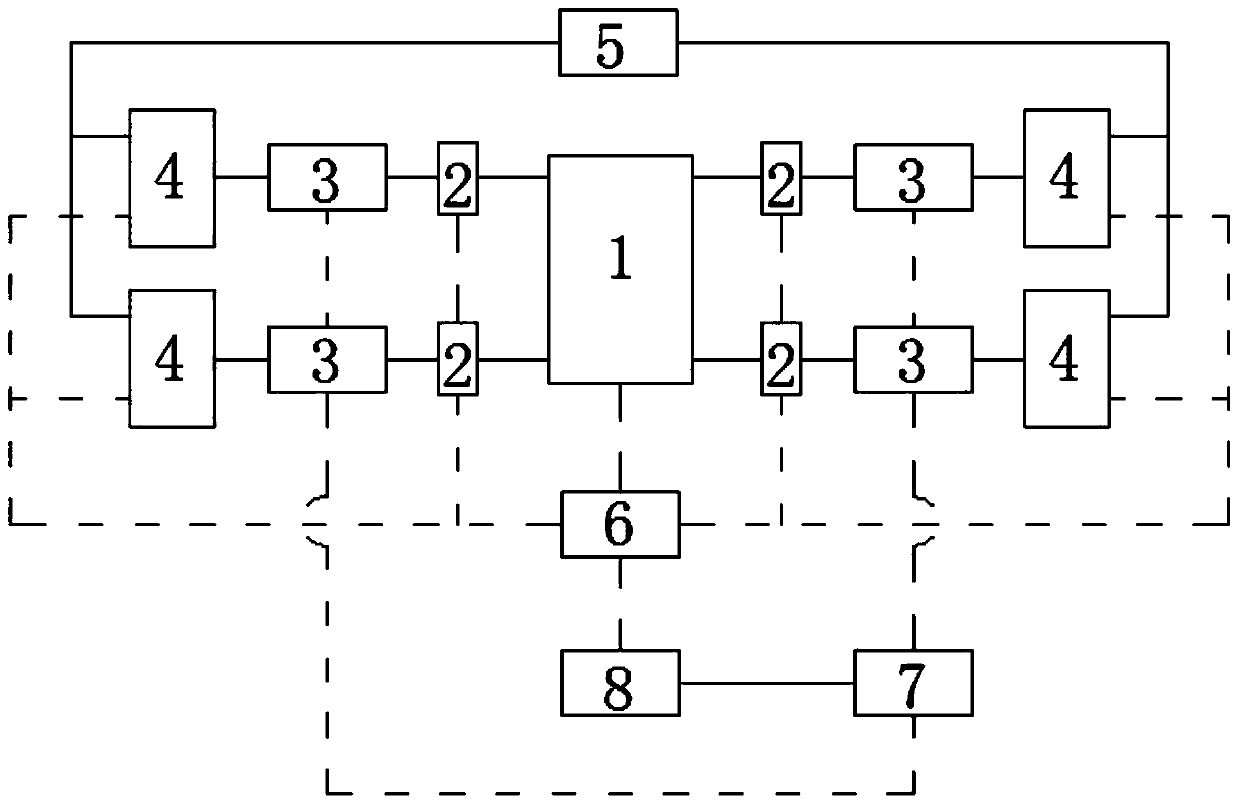

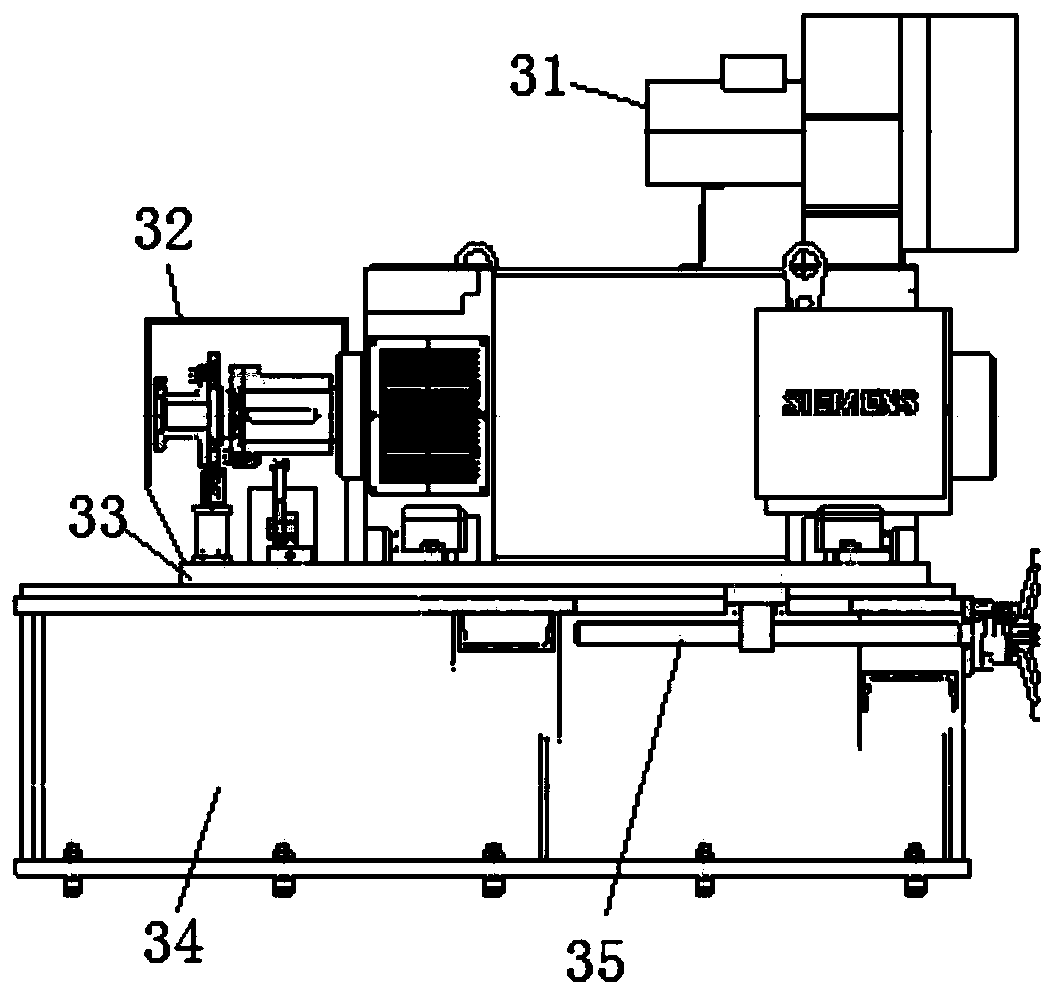

[0017] Such as Figure 1-2 As shown, a four-wheel drive bridge assembly test bench system of the present invention, the four-wheel drive bridge assembly test bench system tests the electric new energy vehicle 1, and the electric new energy vehicle 1 is controlled and operated by the central control system. It is composed of an electrical system and a control system, the electrical system is composed of a dynamometer 3, a drive system 4, and a power supply system 5, the drive system 4 is connected to the dynamometer 3, and the power supply system 5 is connected to the drive system 4 Connect; the control system is made up of a torque sensor 2, a real-time system 6, a data acquisition device 7, and a host computer 8, and the torque sensor 2 is arranged between the dynamometer 3 and the automobile 1, and the real-time system 6 is connected with the vehicle 1 respectively. The drive system 4 and the torque sensor 2 communicate. The data acquisition device 7 is provided with a varie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com