Method for extracting micro plastics from human and animal excreta

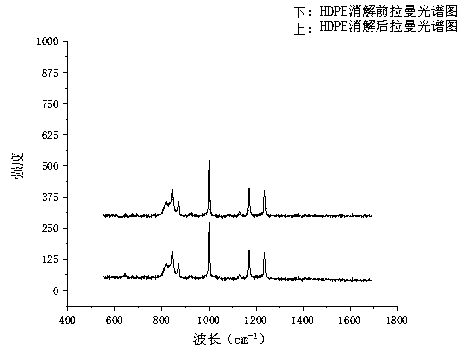

A technology for human and animal excrement and microplastics, applied in chemical instruments and methods, sampling, analysis materials, etc., can solve the problems of severe digestion conditions, inability to separate microplastics, and large damage to microplastics, improving efficiency and facilitating accurate analysis. , the effect of high-fidelity extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

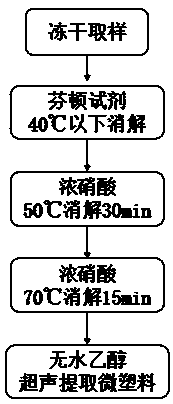

Method used

Image

Examples

Embodiment 1

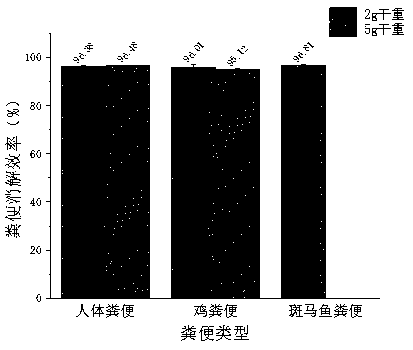

[0045] (1) Feces freeze-drying: freeze-dry the collected human feces in a freeze-drying apparatus, and take 5 g dry weight of the freeze-dried sample, and 3 parallel samples.

[0046] (2) Sample digestion: transfer the freeze-dried stool in step (1) to a 2L beaker, and add 20g / L FeSO to it in turn 4 ·7H 2 O catalyst and 30% H 2 O 2 1:2.5, fully contact the reaction under stirring, until no bubbles are generated, according to 20g / L FeSO 4 ·7H 2 O catalyst and 30% H 2 O 2 The volume ratio of 1:2.5 continues to add Fenton reagent, adding 30% H each time 2 O 2 Do not exceed 50 mL until 500 mL 30% H is added 2 O 2 And the reaction is completed, and the temperature is controlled not to exceed 40°C by using an ice bath during the reaction. Use a circulating water vacuum pump to suction and filter the remaining organic matter onto the water-based CN-CA filter membrane. The number of water-based CN-CA filter membranes is 11, and the water-based CN-CA filter membrane after suction and filtra...

Embodiment 2

[0050] (1) Feces freeze-drying: freeze-dry the collected human feces in a freeze-drying apparatus, and take 2g dry weight of the freeze-dried sample, and 3 parallel samples.

[0051] (2) Transfer the freeze-dried feces in step (1) to a 2L beaker, and add to it in a volume ratio of 20g / LFeSO 4 ·7H 2 O catalyst and 30% H 2 O 2 1:2.5, fully contact the reaction under stirring, until no bubbles are generated, according to 20g / L FeSO 4 ·7H 2 O catalyst and 30% H 2 O 2 The volume ratio of 1:2.5 continues to add Fenton reagent, adding 30% H each time 2 O 2 Do not exceed 50 mL until 200 mL 30% H is added 2 O 2 And the reaction is completed, and the temperature is controlled not to exceed 40°C by using an ice bath during the reaction. Use a circulating water vacuum pump to suction and filter the remaining organic matter onto the water-based CN-CA filter membrane. The number of water-based CN-CA filters is 5, and transfer the water-based CN-CA filter membrane after suction to a 500 mL beaker...

Embodiment 3

[0055] (1) Feces freeze-drying: freeze-dry the fetched chicken excrement in a freeze dryer, take 5g dry weight of the freeze-dried sample, and 3 parallel samples.

[0056] (2) Transfer the freeze-dried feces in step (1) to a 2L beaker, and add to it in a volume ratio of 20g / LFeSO 4 ·7H 2 O catalyst and 30% H 2 O 2 1:2.5, fully contact the reaction under stirring, until no bubbles are generated, according to 20g / L FeSO 4 ·7H 2 O catalyst and 30% H 2 O 2 The volume ratio of 1:2.5 continues to add Fenton reagent, adding 30% H each time 2 O 2 Do not exceed 50 mL until 500 mL 30% H is added 2 O 2 And the reaction is completed, and the temperature is controlled not to exceed 40°C by using an ice bath during the reaction. Use a circulating water vacuum pump to suction and filter the remaining organic matter onto the water-based CN-CA filter membrane. The number of water-based CN-CA filter membranes is 11, and the water-based CN-CA filter membrane after suction and filtration is transferre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com