An unmanned warehouse logistics optimization system and method based on virtual production

A production system and logistics technology, applied in the field of virtual production, which can solve the problems of inability to match the distribution accuracy, inability to try new conditions for trial production, and the recurrence of historical fault bottlenecks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

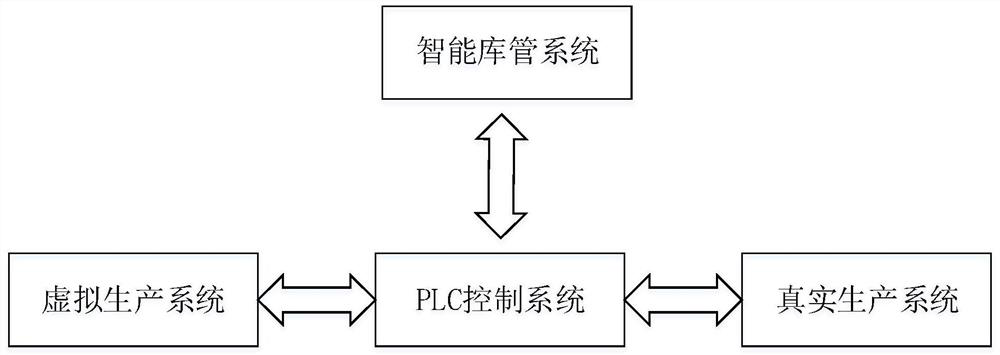

[0031] Such as figure 1 As shown, an unmanned warehouse logistics optimization system based on virtual production provided in this embodiment includes a virtual production system, a real production system, a PLC control system and an intelligent warehouse management system, an intelligent warehouse management system, a PLC control system and a virtual production system The systems are connected in sequence; the intelligent warehouse management system, the PLC control system and the real production system are connected in sequence; the intelligent warehouse management system is used to drive the virtual production model action alone for production trial operation, so as to observe the logistics trend in the virtual production system, The equipment moves and outputs indicators that can evaluate the operation efficiency; the intelligent warehouse management system is also used to drive the virtual production model and the real production site to act simultaneously, predict the lin...

Embodiment 2

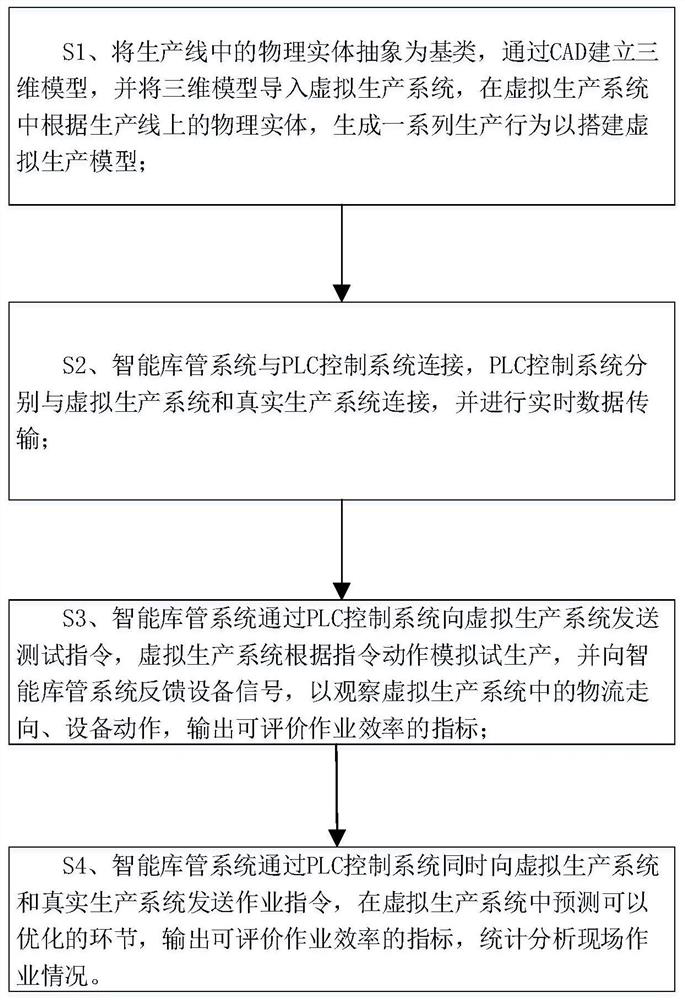

[0038] Such as figure 2 As shown, an unmanned warehouse logistics optimization method based on virtual production includes the following steps:

[0039] S1. Abstract the physical entities in the production line as a base class, and write attribute information in the abstract base class: ID, name, location, status (such as waiting, working, blocking and maintenance, etc.) and statistics (input productivity, utilization rate) and other information; establish a 3D model through CAD, and import the 3D model into the virtual production system. In the virtual production system, according to the physical entities on the production line, a series of production behaviors are generated to build a virtual production model;

[0040] S2. Connect the intelligent warehouse management system and PLC control system with the virtual production system and the real production system respectively by using industrial Ethernet, and perform real-time data transmission to realize the information of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com