Multi-stack fuel cell system and control method thereof, and vehicle

A technology of a fuel cell system and a control method, which is applied to fuel cells, power system fuel cells, electric vehicles, etc., can solve problems such as battery performance degradation, long heating time of fuel cells, and slow startup.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

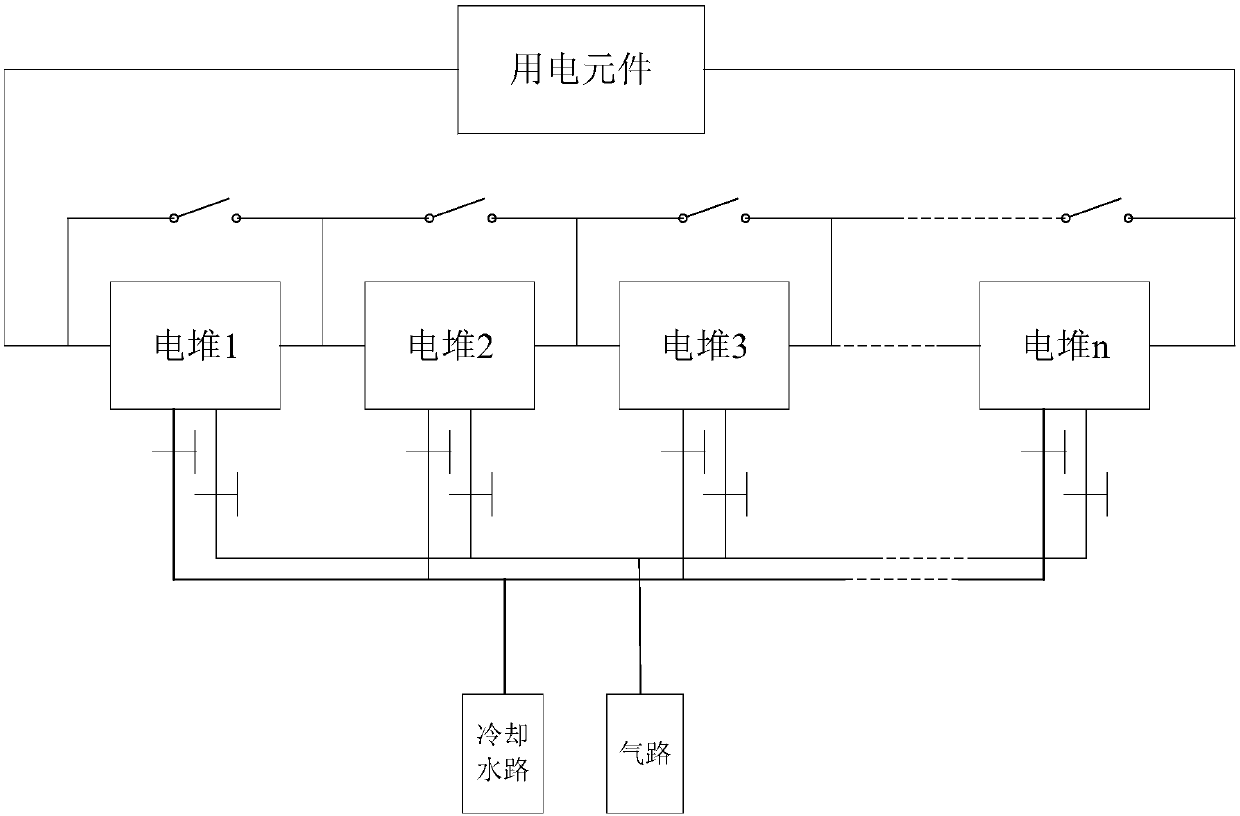

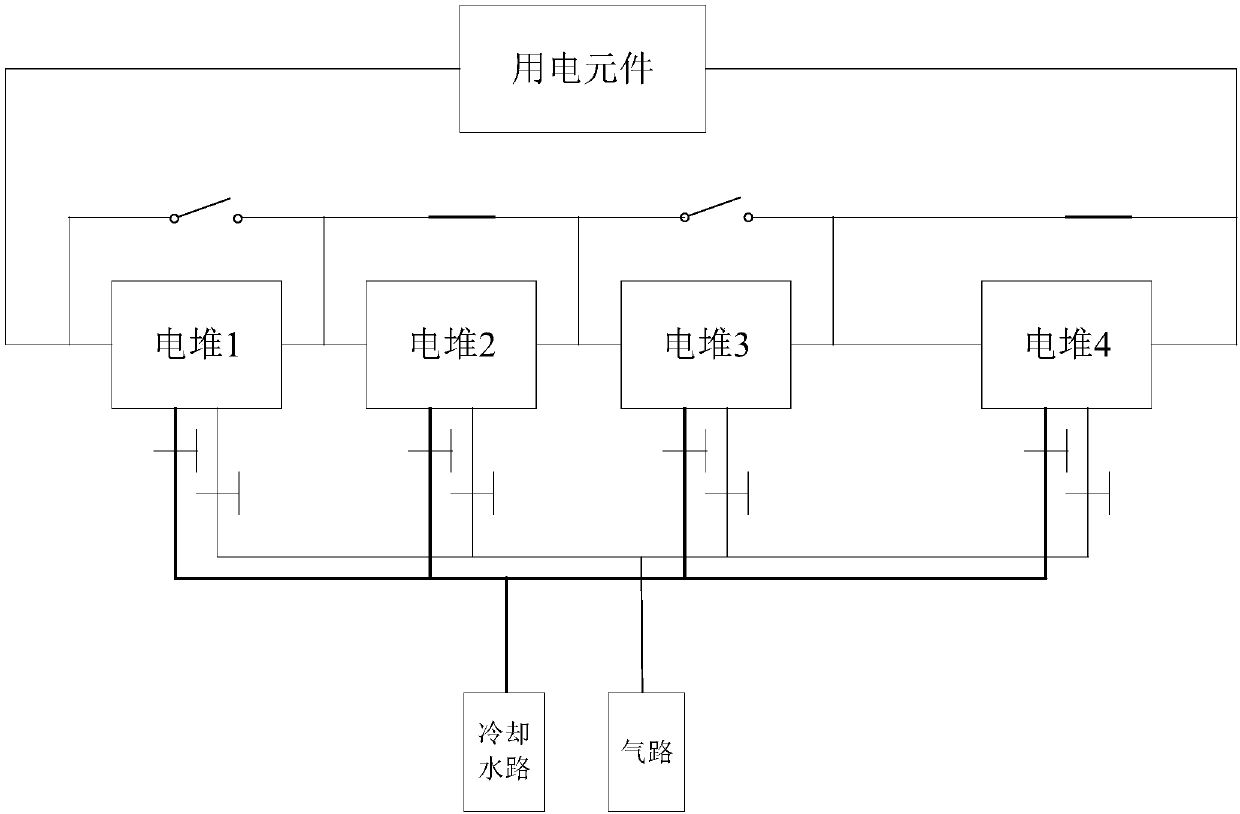

[0019] Embodiment 1 provides a vehicle, which is provided with a multi-stack fuel cell system and electrical components, wherein the stack module of the fuel cell can be composed of several stacks connected in series, such as figure 1 Shown is a structural diagram of a fuel cell system in which stacks are connected in series, including a series power supply circuit, which connects electrical components to supply power; in the series power supply circuit, the power supply circuit connects fuel cell stacks in series, and connects A corresponding short-circuit circuit is set between the positive and negative poles, and a control switch is set on the short-circuit circuit to control the opening or closing of the electric stack to which the control switch belongs, and then control the number of electric stacks actually running.

[0020] Such as figure 1 As shown, the system also includes a cooling water pipeline, the cooling water pipeline is connected to all electric stacks throug...

Embodiment 2

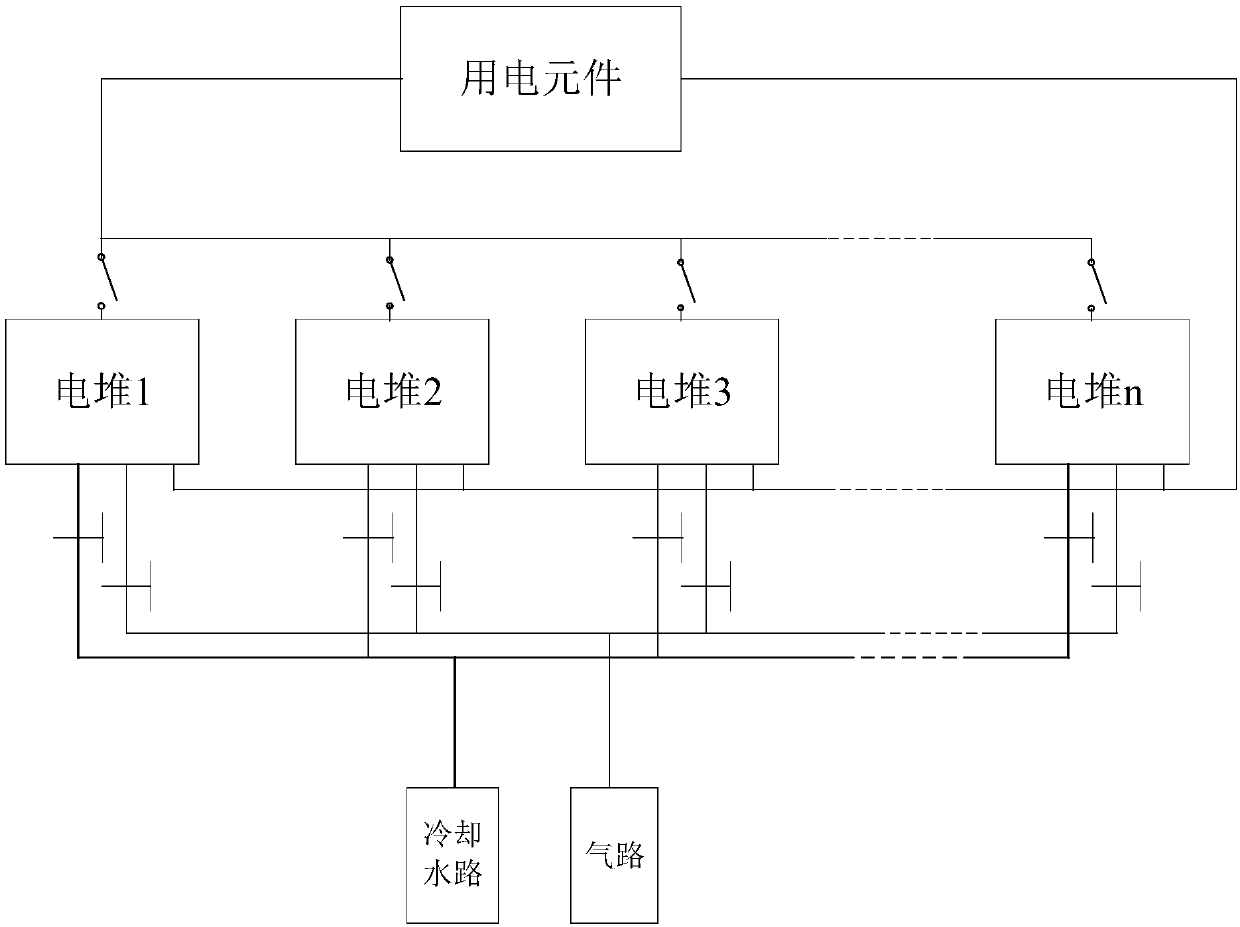

[0031] Embodiment 2 provides a vehicle, which is provided with a multi-stack fuel cell system and electrical components, wherein the stack module of the fuel cell can be composed of several stacks connected in parallel, such as image 3 Shown is the structure diagram of the fuel cell system in which stacks are connected in parallel, including a power supply circuit, which is connected to electric components for power supply; Control switches are respectively arranged on the branches to control the opening or closing of the electric stacks to which the control switches belong, and further control the number of electric stacks in actual operation.

[0032] Such as image 3 As shown, the system also includes a cooling water pipeline, the cooling water pipeline is connected to all electric stacks through a cooling branch, and an electromagnetic water valve can be set on each cooling branch connected to each electric stack to independently control the cooling of each electric stack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com