Plug adopting plastic package terminal component and self-sealing bolt locking power connector

A technology for sealing terminals and plugs, which is applied in the direction of vehicle connectors, clamping/spring connections, connections, etc. It can solve problems such as difficult sealing, loss, and burning of equipment, so as to improve production efficiency, ensure appearance, and meet overall sealing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments. In this embodiment, the position where the plastic-sealed terminal part is located is defined as "front", and the position where the tail button cover is located is defined as "rear".

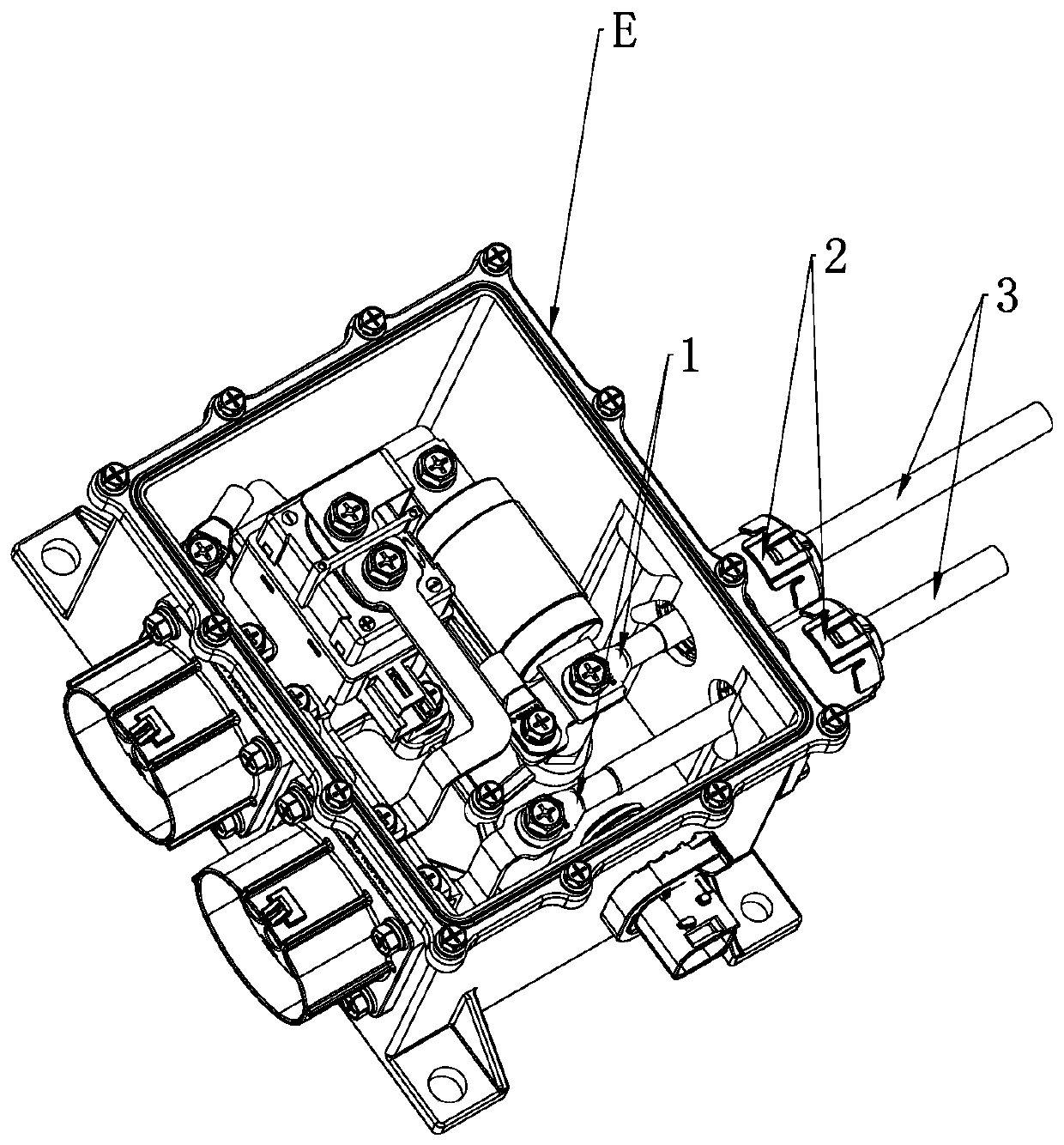

[0036] see Figure 4 , A plug in this embodiment includes a plastic-sealed terminal part 4 , a straight sleeve 5 , a sealing body 6 , and a tail buckle cover 7 .

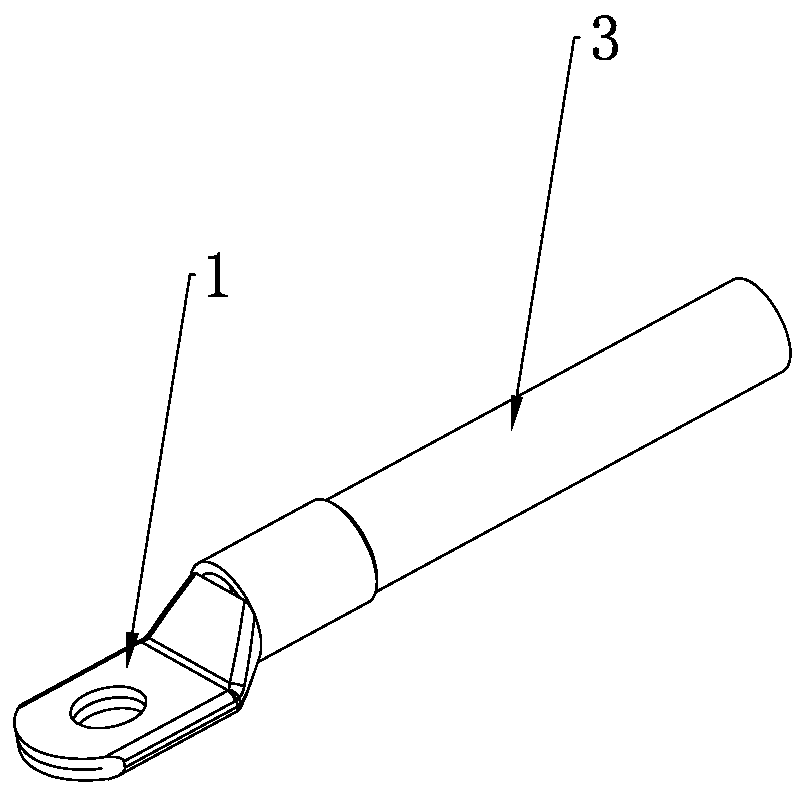

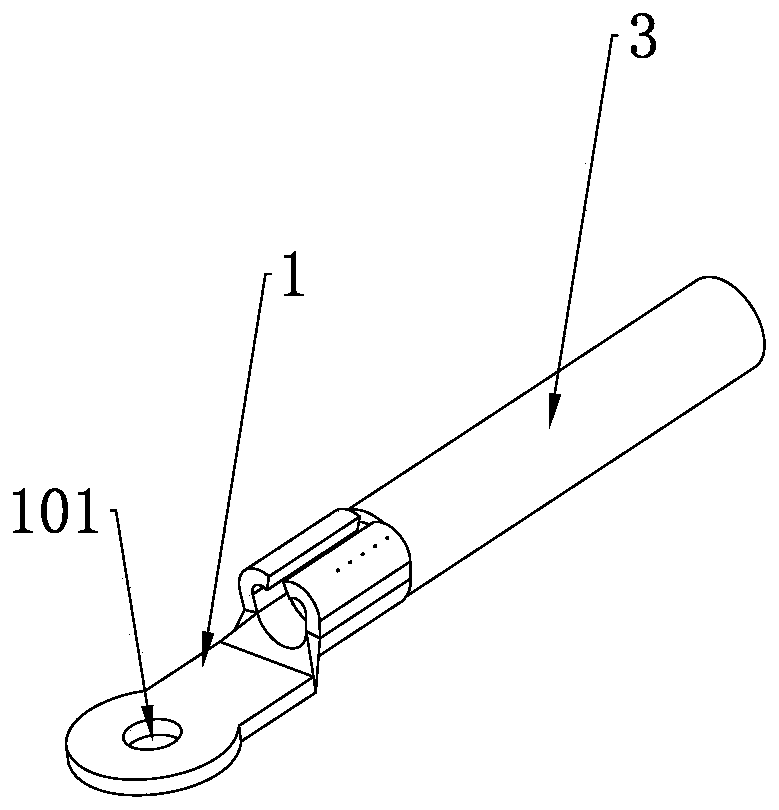

[0037] see Figure 5 and Image 6 , the plastic-sealed terminal component 4 is an integrated component formed by plastic-sealing the terminal 1 alone, including the terminal 1 and the first plastic-sealed housing 401 formed by plastic-sealing the terminal. In this embodiment, only the terminal is plastic-sealed, and the terminal The connected cables are not plastic-encapsulated, which can eliminate the risk of plastic-encapsulated wires. The first plastic casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com