Modular multilevel topology and its control method based on coupled inductor dual-buck sub-module

A modular multi-level, coupled inductor technology, applied in electrical components, output power conversion devices, AC power input conversion to DC power output, etc., can solve the short circuit of DC side capacitors, output AC voltage distortion, and reduce power quality etc. to achieve the effects of reducing voltage distortion rate, improving effectiveness and reliability, and improving dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with the accompanying drawings.

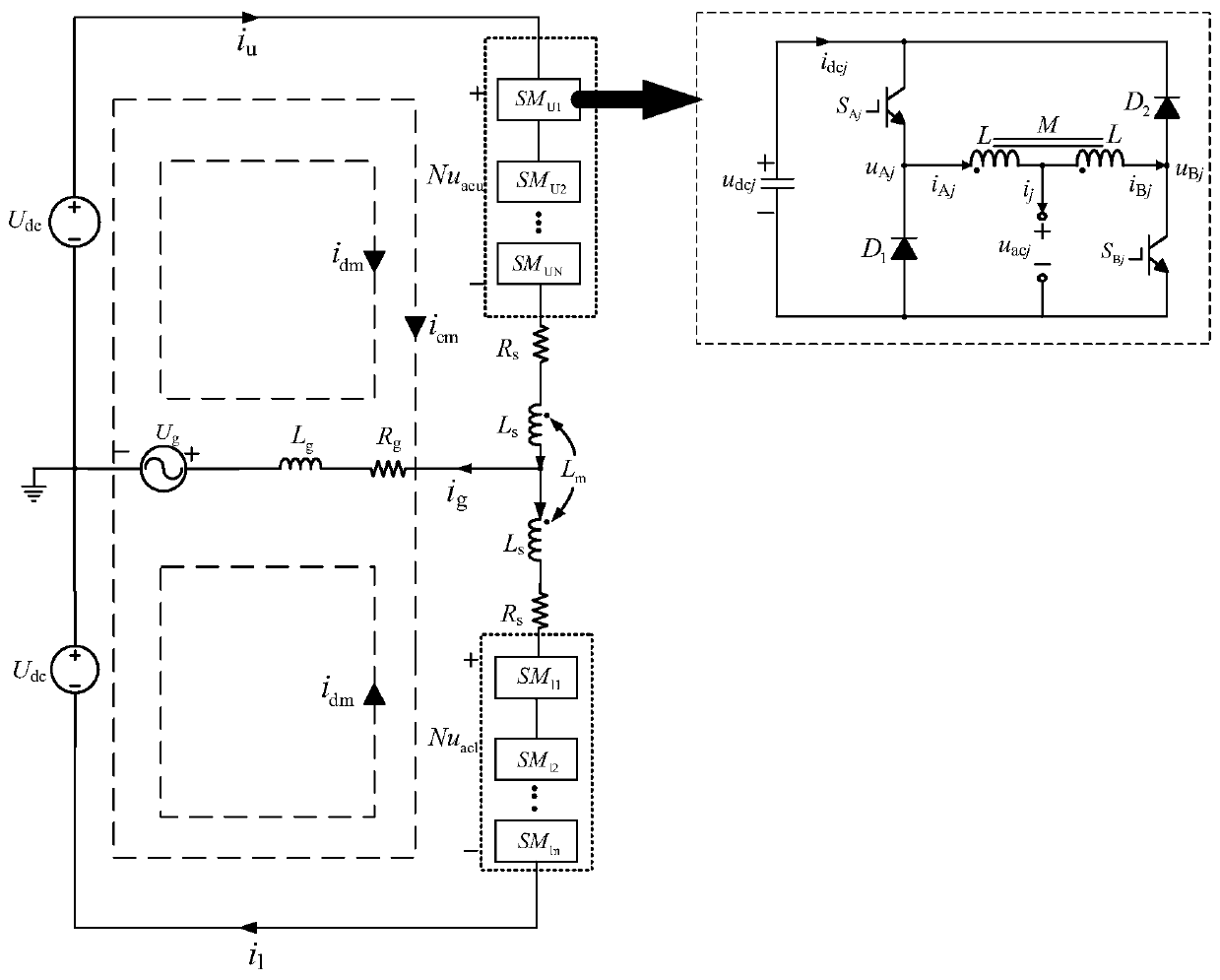

[0025] Such as figure 1 As shown on the left side of , the topology of the modular multilevel converter based on the coupled inductor double-step-down sub-module of the present invention includes: two groups of identical coupled-inductor double-step-down sub-modules and coupled inductor L m . Each group of sub-modules includes N end-to-end sub-modules. The first group of submodules SM u1 to SM uN Located in the upper bridge arm, and the first submodule SM U1 The first end of the terminal is connected to the positive pole of the external DC system, and the second group of sub-modules SM l1 to SM lN Located in the lower bridge arm, and the Nth sub-module SM lN The tail end is connected to the negative pole of the external DC system. Wherein, the external direct current system includes a direct current voltage source. The Nth submodule SM in the first group of submo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com