Use of taking cellulose diacetate pulp as cigarette filter rod

A technology of cellulose diacetate and filter rod, which is applied in the direction of e-liquid filter, application, tobacco, etc., can solve the problems of low filtering effect of filter rod and cumbersome production process, and achieves good adsorption and filtering effect, high application value, and large pores. The effect of rate and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

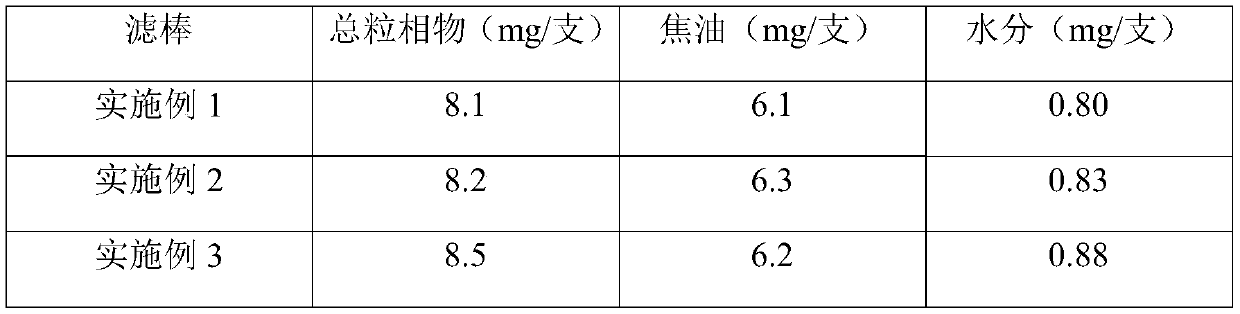

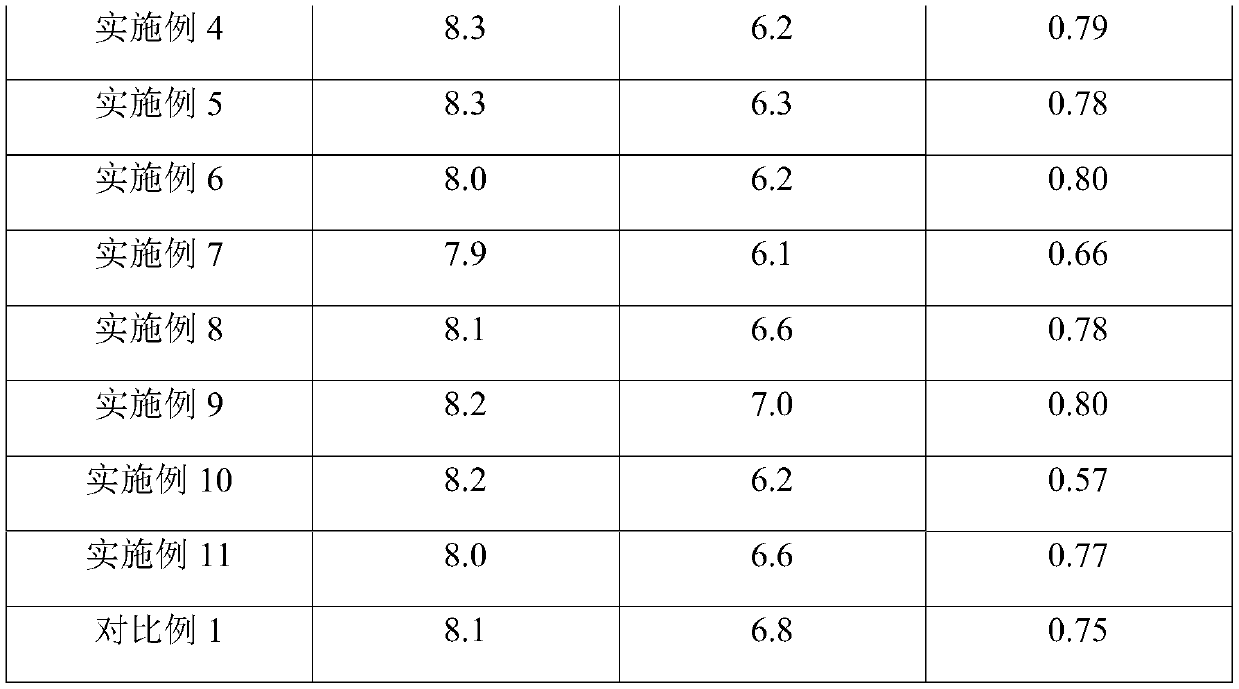

[0045] In this embodiment, a kind of cellulose diacetate pulp is provided as a cigarette filter rod

[0046]Mix cellulose diacetate and PVDF at a solid content ratio of 20:1, and use dimethylacetamide as a solvent to prepare a slurry with a solid content of 10%. The temperature is 40°C, and it is transported to the Venturi at a pressure of 5 MPa. In the coagulation bath of the tube, the initial pulp is obtained, and then the throat of the Venturi tube is repeatedly rinsed 10 times with deionized water to obtain cellulose diacetate pulp, which is freeze-dried in the mold and used as a cigarette filter rod after demoulding . Among them, the scanning electron microscope image of cellulose diacetate pulp is shown in figure 1 As shown, the diameter of cellulose diacetate in traditional filter rods is generally about 25 μm, while the diameter of cellulose diacetate pulp fibers prepared by us is less than 1 μm, which increases the specific surface area for adsorption.

Embodiment 2

[0048] In this embodiment, a kind of cellulose diacetate pulp is provided as a cigarette filter rod

[0049] Mix cellulose diacetate and PS at a solid content ratio of 50:1, and mix dimethylacetamide and dimethyl sulfoxide at a volume ratio of 1:1 as a solvent to prepare a slurry with a solid content of 8%. The temperature is 80°C, and the pressure is 4 MPa, and it is transported to the coagulation bath of the Venturi tube to obtain the initial pulp, and then the throat of the Venturi tube is repeatedly washed 10 times with deionized water to obtain the cellulose diacetate pulp. After being freeze-dried in a mold, it can be used as a cigarette filter rod after demoulding.

Embodiment 3

[0051] In this embodiment, a kind of cellulose diacetate pulp is provided as a cigarette filter rod

[0052] Mix cellulose diacetate and PAN at a solid content ratio of 100:1, use dimethyl sulfoxide as a solvent, and prepare a slurry with a solid content of 12%, at a temperature of 30°C, and transport it to the Venturi at a pressure of 7 MPa In the coagulation bath of the tube, the initial pulp is obtained, and then the throat of the Venturi tube is repeatedly rinsed 8 times with deionized water to obtain cellulose diacetate pulp, which is freeze-dried in the mold and used as a cigarette filter rod after demoulding .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com