Magnetic ionic liquid, applications thereof, modified active carbon, and preparation method thereof

A magnetic ionic liquid and activated carbon technology, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of combustion and explosion biomass activated carbon modification effects, etc., to reduce the possibility of spontaneous combustion and explosion, increase adsorption capacity, and spontaneous ignition point Elevated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

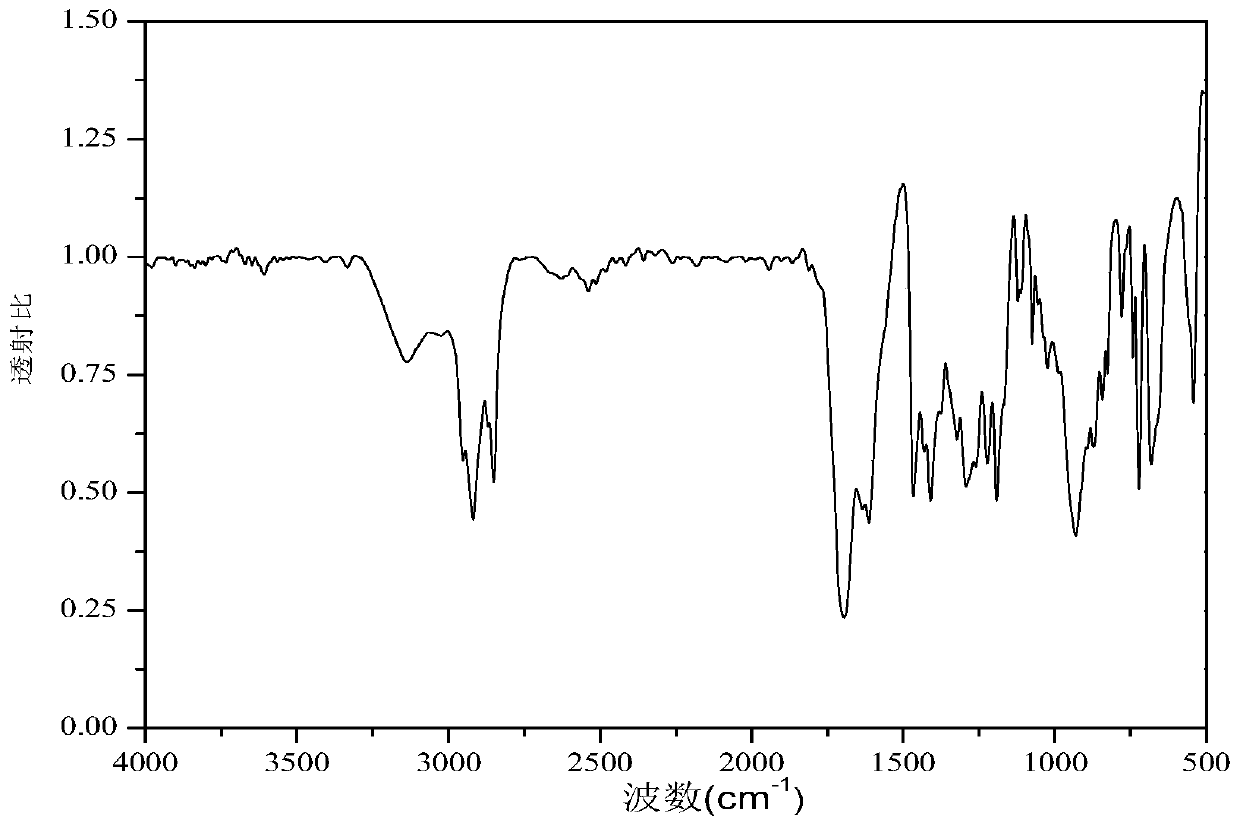

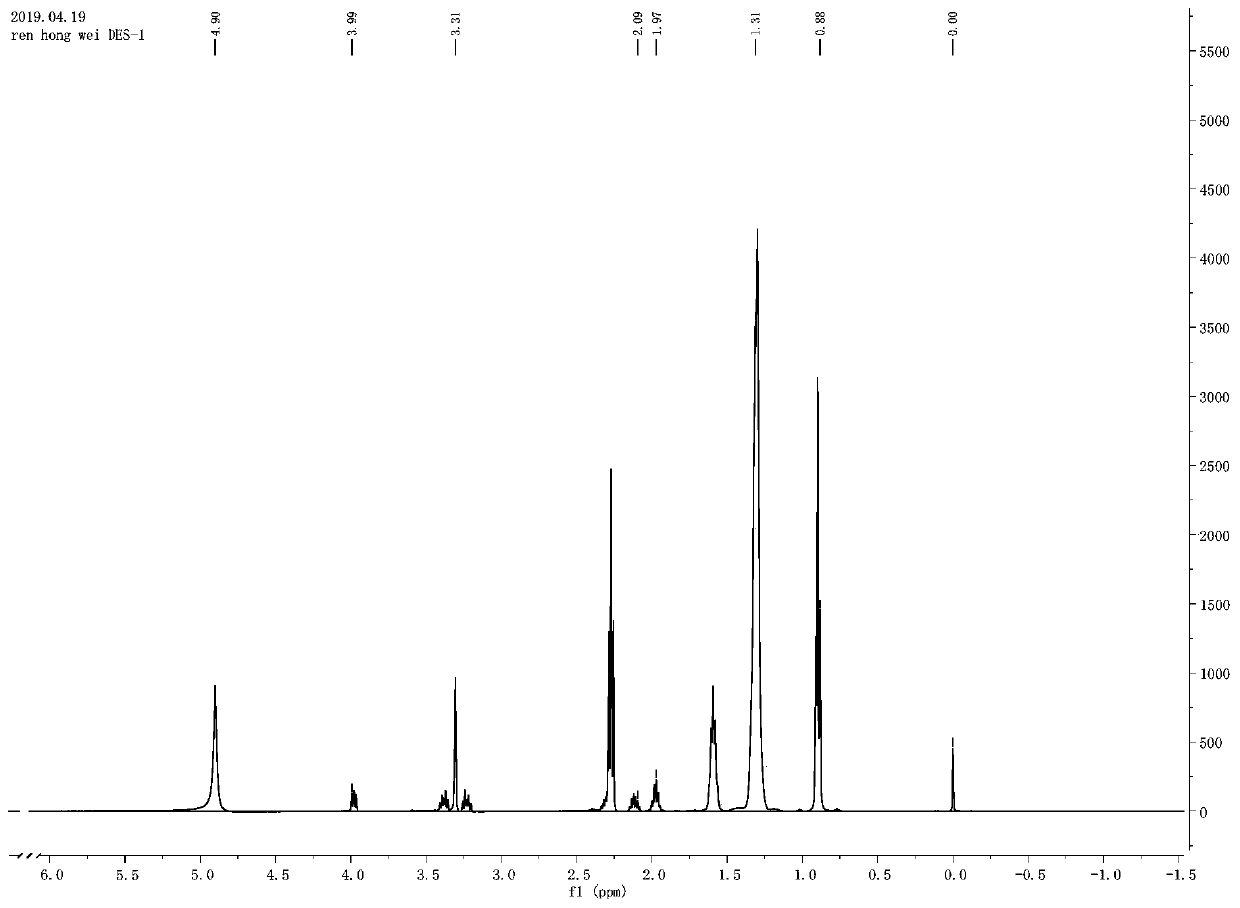

[0030] A magnetic ionic liquid consisting of 1,3-dimethylurea, alanine and NiCl in a molar ratio of 2:2:1 2 ·6H 2 O is prepared, and the concrete steps are as follows:

[0031] 0.4mol of 1,3-dimethylurea, 0.4mol of alanine and 0.2mol of NiCl 2 ·6H 2 O was placed in a 200mL three-necked flask, and the temperature was raised to 60°C at a heating rate of 5.5°C / h, kept warm and stirred for 10h to obtain a transparent liquid, which was then vacuum-dried at 60°C for 24h to obtain the magnetic ionic liquid A.

Embodiment 2

[0033] A kind of magnetic ionic liquid, is 2:4:3 valine, thiourea and ZnCl by molar ratio 2 ·6H 2 O is prepared, and the concrete steps are as follows:

[0034] 0.4mol valine, 0.8mol thiourea and 0.6mol ZnCl 2 ·6H 2 O was placed in a 200mL three-neck flask, and the temperature was raised to 50°C at a heating rate of 6°C / h, kept warm and stirred for 8h to obtain a transparent liquid, which was then vacuum-dried at 60°C for 24h to obtain the magnetic ionic liquid B.

Embodiment 3

[0036] A magnetic ionic liquid consisting of phenylalanine, benzamide and CoCl in a molar ratio of 2:6:1 2 ·6H 2 O is prepared, and the concrete steps are as follows:

[0037] 0.4mol phenylalanine, 1.2mol benzamide and 0.2mol CoCl 2 ·6H 2 O was placed in a 200mL three-necked flask, and the temperature was raised to 75°C at a heating rate of 5.5°C / h, kept warm and stirred for 8h to obtain a transparent liquid, which was then vacuum-dried at 60°C for 24h to obtain magnetic ionic liquid C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com