Laser punching and cutting system for semiconductor materials

A laser drilling and cutting system technology, applied in laser welding equipment, welding/cutting auxiliary equipment, welding/welding/cutting items, etc., can solve the problem of low accuracy, influence of infrared ranging sensor measurement accuracy, and inconvenience of semiconductor drilling and other problems to achieve the effect of ensuring accuracy, simple structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

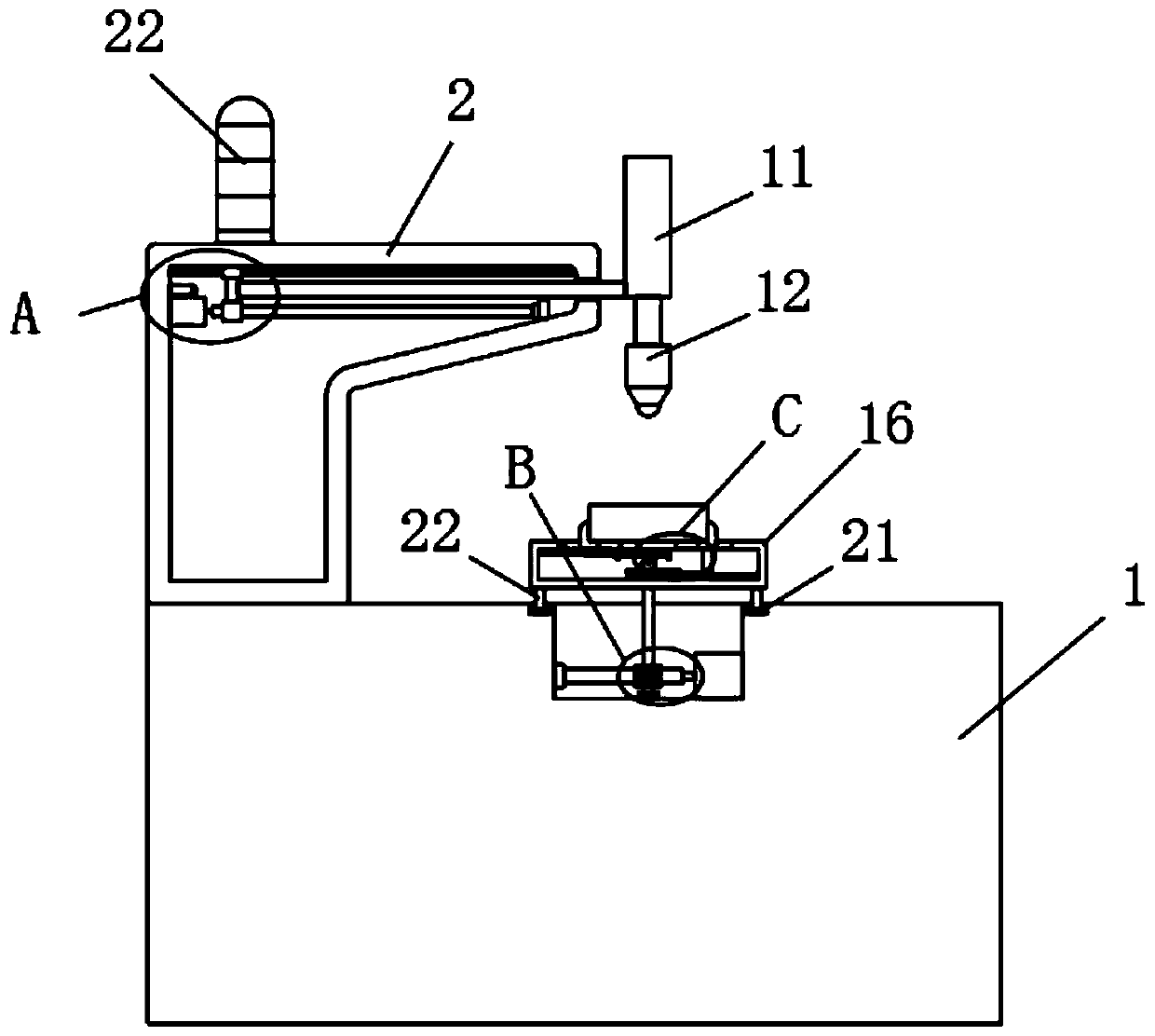

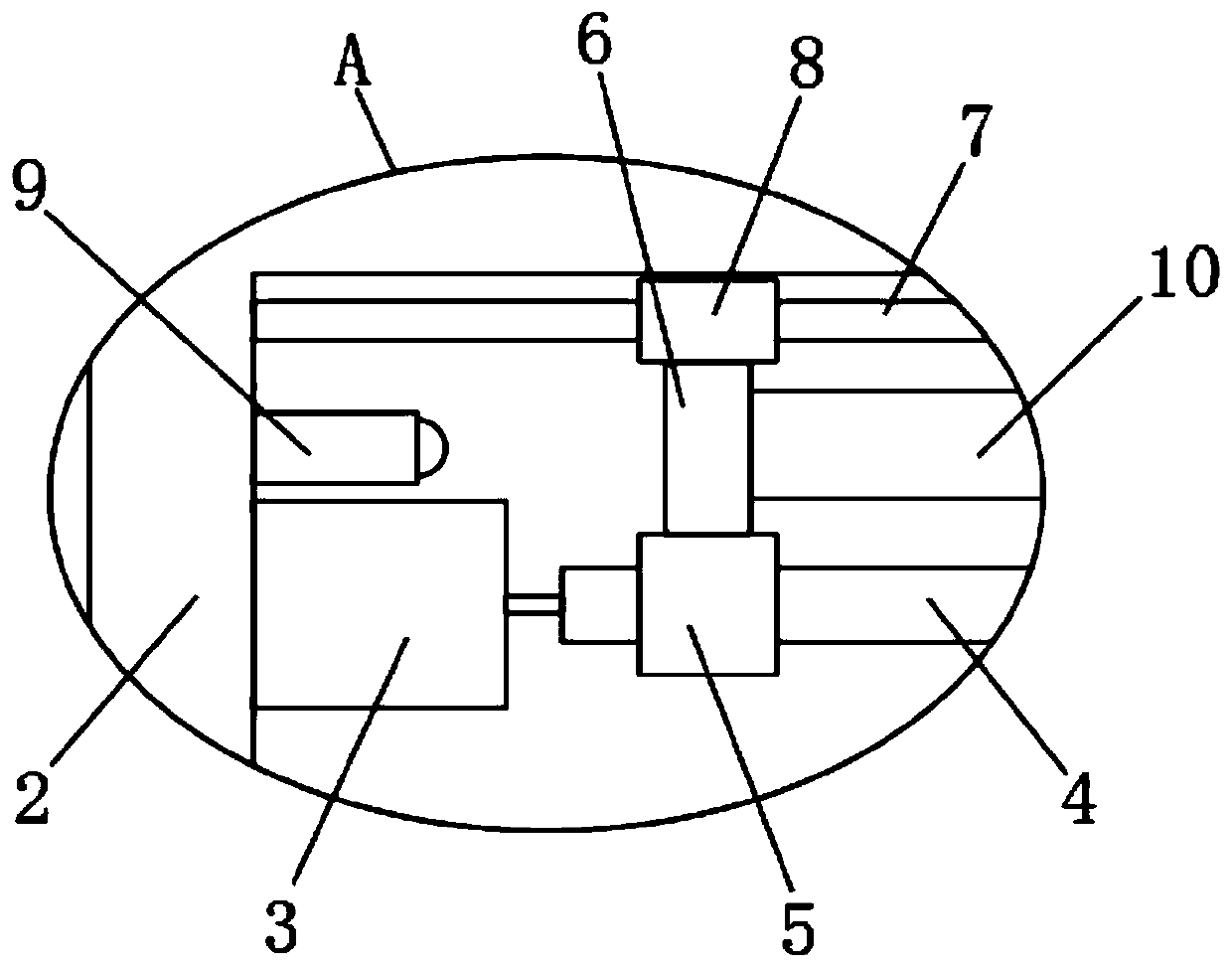

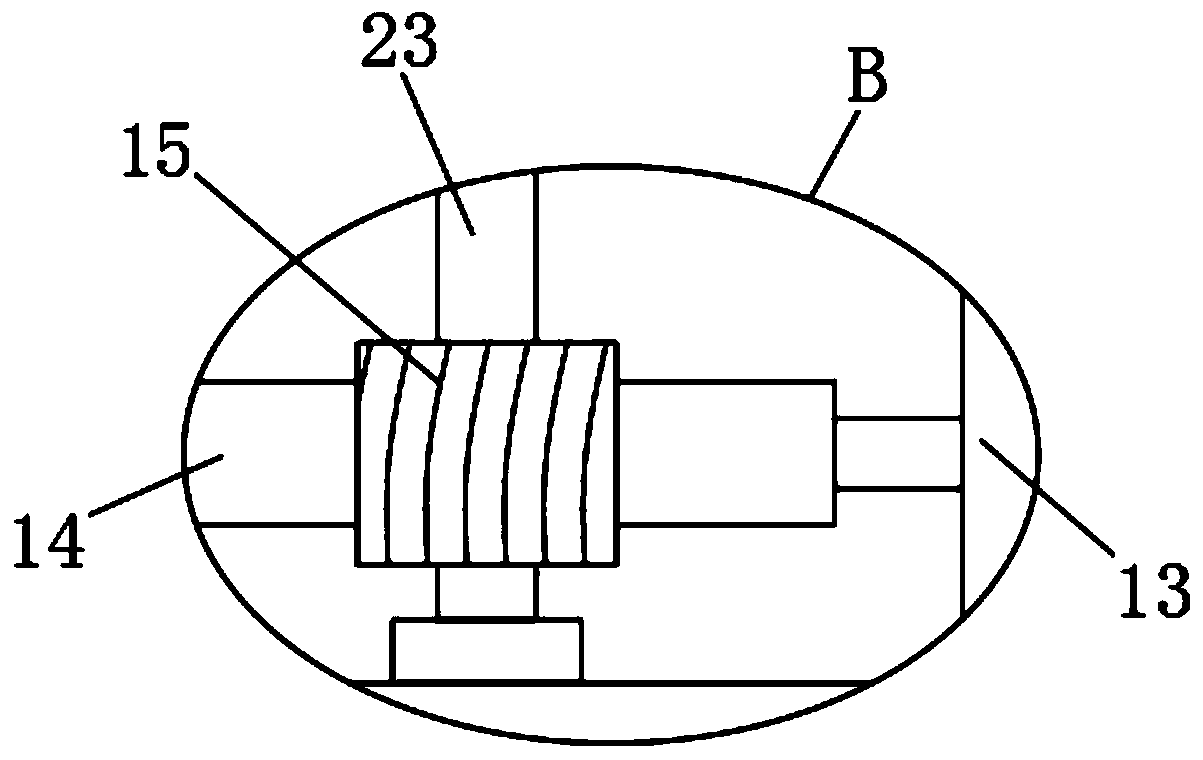

[0021] refer to Figure 1-4 , a laser drilling and cutting system for semiconductor materials, comprising a base 1, the upper side wall of the base 1 is fixedly connected with a mounting seat 2, the upper end side wall of the mounting seat 2 is fixedly connected with a multi-color warning light 22, and the multi-color warning light Lamp 22 adopts red, yellow and green. When green, it shows that the work is safe. When it is red and yellow, it shows that there is a mistake in the punching process, and reminds the workers to carry out maintenance. The multi-color warning lights 22 are electrically connected with the infrared ranging sensor 9 and the servo motor respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com