A high-temperature pallet self-locking nut processing technology

A processing technology and self-locking nut technology, which is applied in the field of high-temperature pallet self-locking nut processing technology, can solve the problem of high tool consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

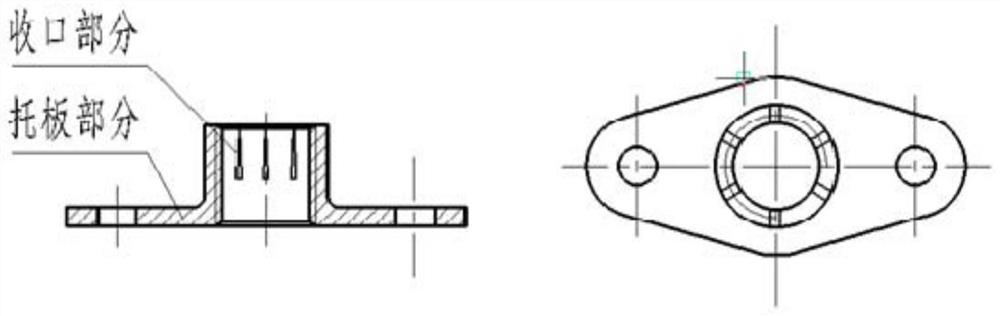

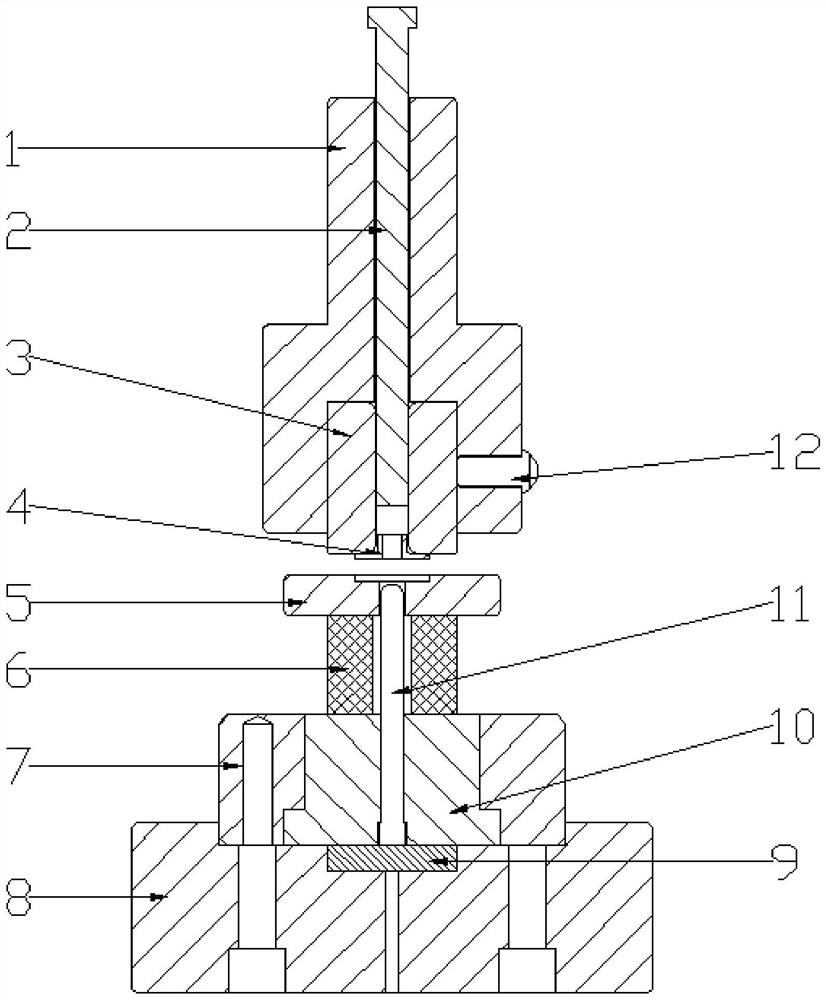

[0011] Embodiment 1: A kind of high-temperature supporting plate self-locking nut processing technology, the specific steps of this processing technology are: (1) material preparation: the material of nut body is selected high-temperature-resistant alloy GH2132 (A286) sheet material; (2) blanking: put the resistant The high-temperature alloy sheet is blanked according to the mold specifications: (3) Stretch forming: the high-temperature alloy sheet is fixed with a mold, and stretched and formed several times. When necessary, lubricant is added between the mold and the high-temperature alloy sheet. The mold includes a base 8 And the die handle 1 fixedly connected with the stamping machine, the base 8 is embedded with a punch holder 7, the base 8 and the punch holder 7 are fixed by bolts, and the punch holder 7 is covered with a lower punch holder 10 , the lower punch fixing sleeve 10 is provided with a lower punch 11, the bottom of the lower punch 11 is provided with a backing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com