A high-pressure phosphorus removal auxiliary device

An auxiliary device, high-pressure technology, applied in the direction of cleaning methods using liquids, manufacturing tools, chemical instruments and methods, etc., can solve the problems of dust pollution, affecting production, and difficulty in meeting process requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

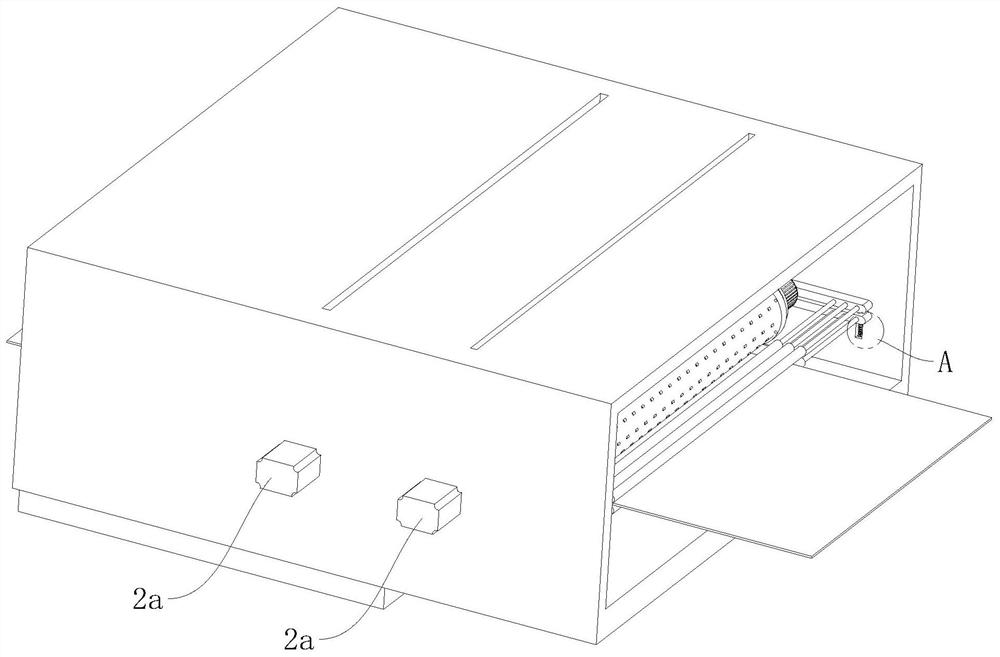

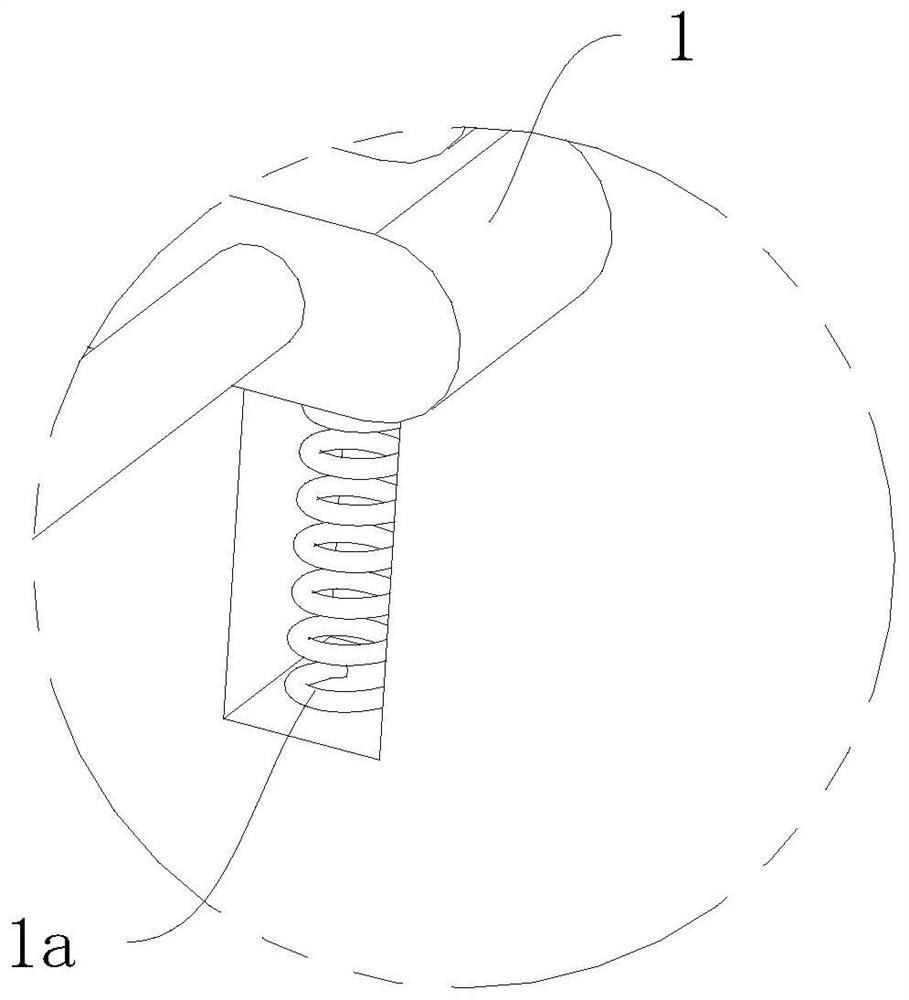

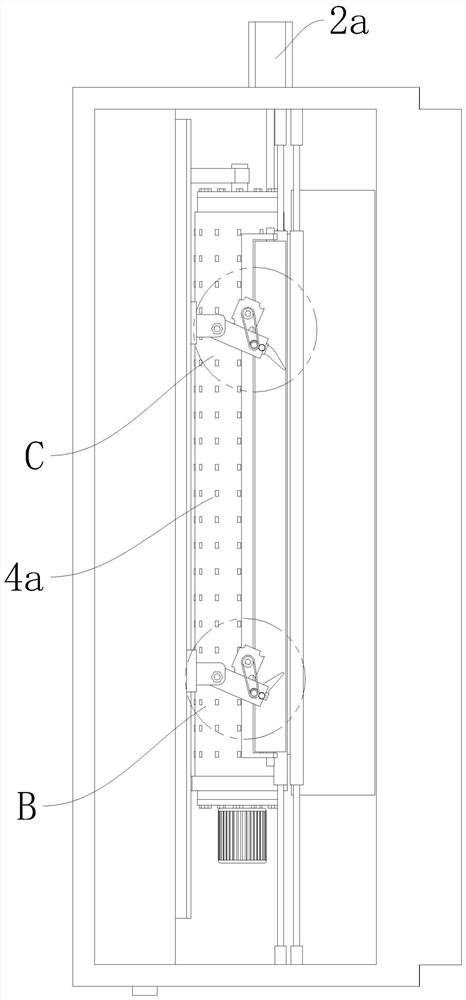

[0040] refer to Figure 1 to Figure 12 The high-pressure dephosphorization auxiliary device shown includes a dephosphorization bin, which is equipped with vibrating rollers and high-pressure rejectors close to its left and right ends respectively. There are two or more sets of pinch rollers on both sides of each vibrating roller, and a set of pinch rolls between the two adjacent sets of pinch rolls and next to the set of pinch rolls closest to the outlet of the dephosphorization bin There is a grinding and washing roller 2 on each side, and the vibrating roller includes an upper beam frame 3, a transfer cylinder 4, a planetary hollow roller 5 and a frequency conversion motor 5b. The end is suspended downwards, the transmission cylinder 4 is horizontally hinged in the free end of the upper beam frame 3, the planetar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com