High-strength heat-resistant deformation magnesium alloy material and preparation method thereof

A heat-resistant deformation and magnesium alloy technology, which is applied in the field of magnesium alloy production in non-ferrous metals, can solve the problems of high alloy cost and achieve the effects of improving alloy fluidity, excellent elongation, and grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

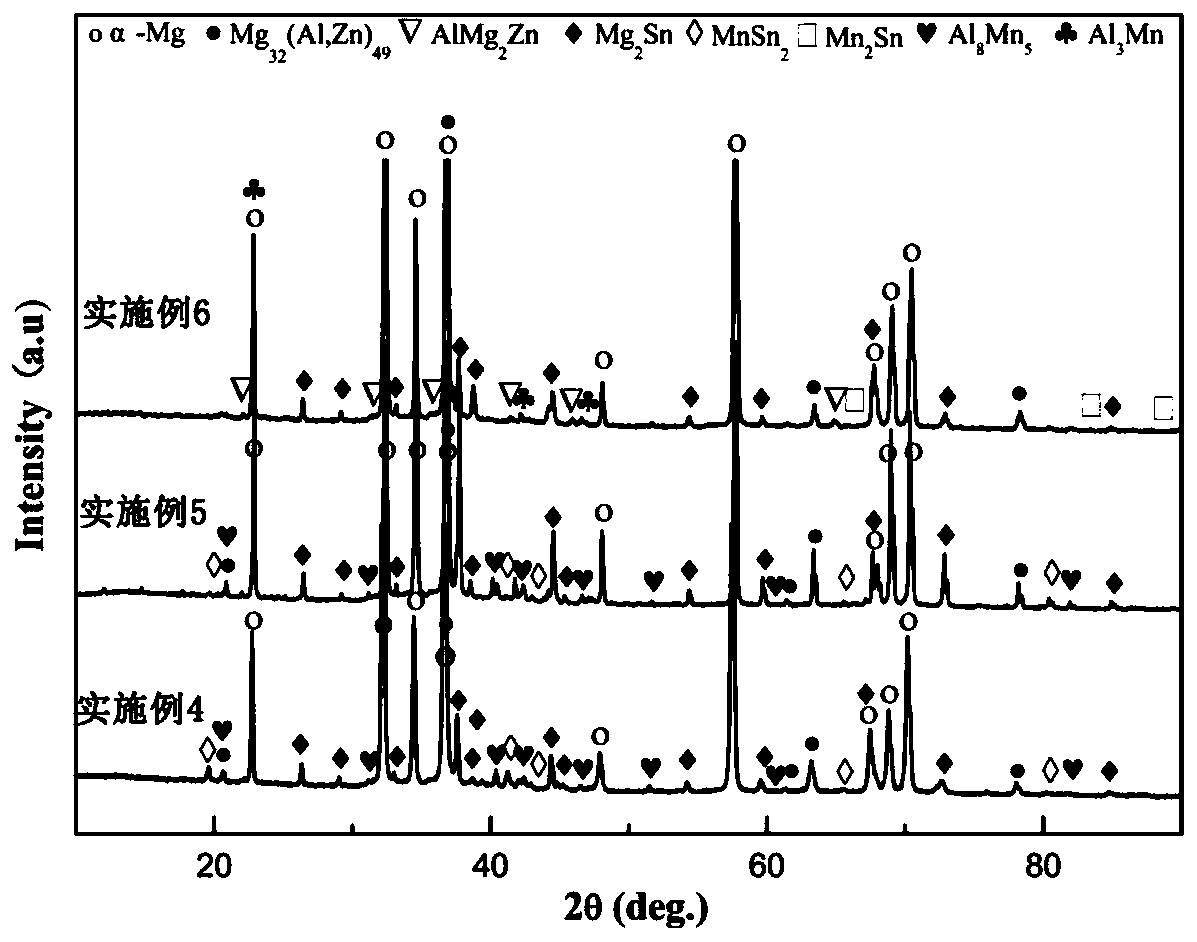

[0070] Table 1 shows the mass percentages of the components of each Mg-Zn-Sn-Mn-Al deformed magnesium alloy in 14 groups of examples.

[0071]

[0072]

[0073] The technical solutions in the embodiments of the present invention will be clearly and completely described below. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0074] Including the above 14 embodiments, any one of the high-strength, high-strength, high-temperature, high-plasticity high-strength heat-resistant deformable magnesium alloys at room temperature includes the stages of smelting, extrusion and heat treatment processes during preparation;

[0075] (1) Smelting: with pure Mg, pure Zn, pure Sn, pure Al, Mg-10wt.% Mn as raw mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com