Floor tile based on marble stone materials and preparation method thereof

A marble and floor tile technology, applied in the field of marble-based floor tiles and its preparation, can solve the problems of single function, high cost, unsuitable for diversified living needs, etc., and achieve time saving, improved anti-slip performance, and excellent environmental protection effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

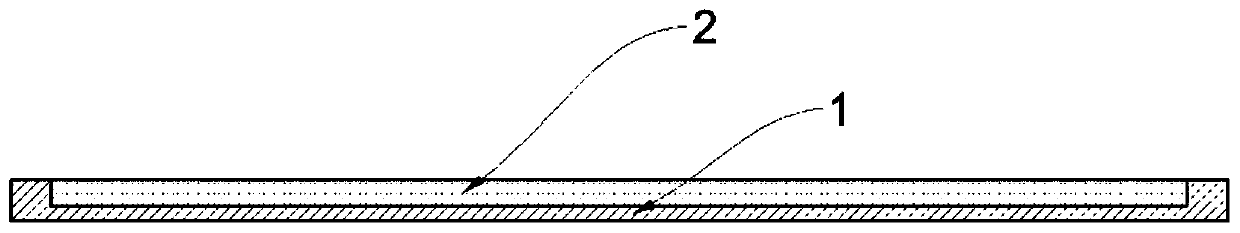

[0034] Such as figure 1 Shown: a floor tile based on marble material described in this embodiment, including a base brick 1 and a decorative brick 2; the base brick 1 is in a "concave" shape, and the decorative brick 2 is filled in the "concave" shape; The base brick 1 is made of a blank made of clay, quartz sand, and feldspar, and the facing brick 2 is made of the blank and marble waste; the base brick 1 and the facing brick 2 are integrally formed by sintering.

[0035] Structurally, this embodiment adopts the base brick 1 to wrap the facing brick 2 (marble base), and the "concave" wrapping effect makes the integrity of the floor tile better. The decorative tile 2 will make the surface of the floor tiles have the effect of marble floor tiles (excellent durability and aesthetics), and the overall marble content used is greatly reduced compared with normal marble floor tiles, which saves the cost of floor tiles. In a preferred embodiment: the thickness of the underside of the...

Embodiment 2

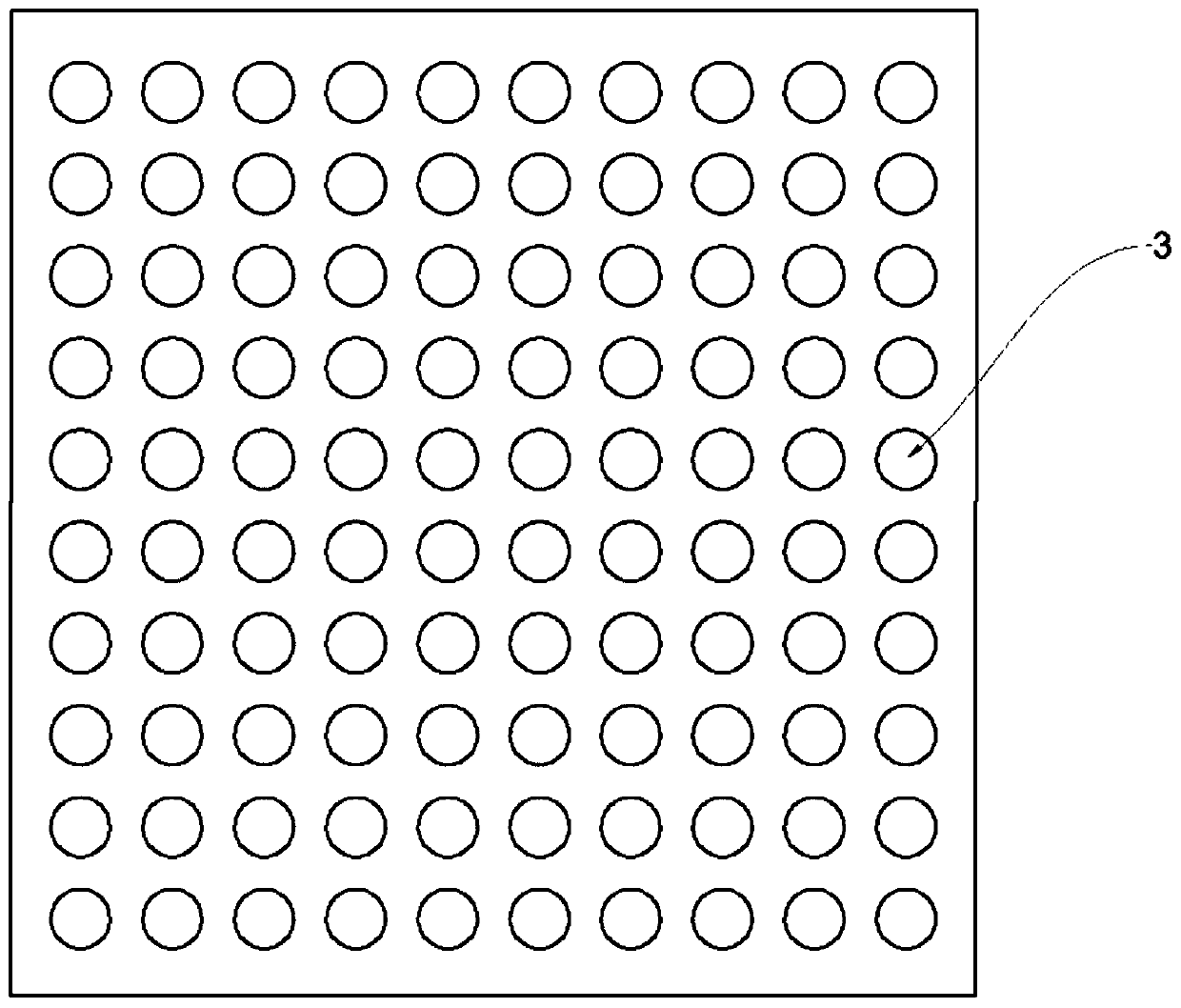

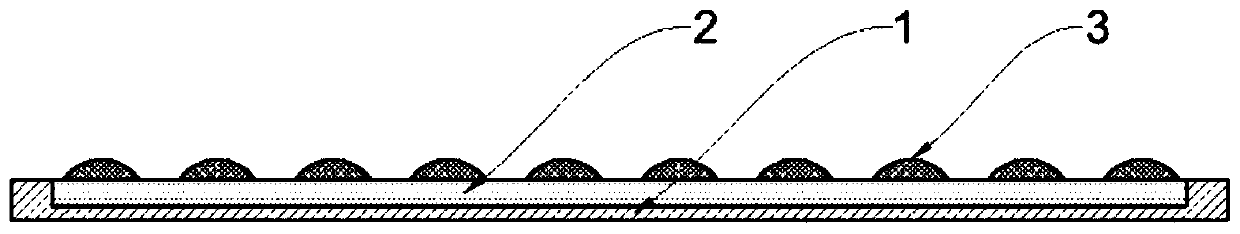

[0048] Such as figure 2 , image 3 As shown: the present embodiment has made the following changes on the basis of embodiment 1. The upper surface of the decorative brick 2 is provided with a number of anti-slip blocks 3, and the anti-slip blocks 3 are mushroom-shaped and arranged in an array (the present embodiment The anti-slip block 3 can change the shape of the decorative brick 2 through the mold and sinter it into one piece. It can also be installed separately in the later stage, such as: opening a hole on the decorative brick 2 to embed the anti-slip block 3 or opening a threaded hole on the decorative brick 2 to pass through the anti-slip block 3. The lower part is provided with external thread through mechanical connection, etc., because the above-mentioned method is relatively mature in the prior art, so it will not be elaborated here.). The overall anti-slip performance of the floor tiles can be greatly improved by the setting of the anti-slip block 3, and the shape ...

Embodiment 3

[0050] Such as Figure 4 As shown: this embodiment has been optimized on the basis of embodiment 2, specifically as follows: the anti-slip block 3 includes a massage head 31, an elastic member 32, and a rubber sleeve 33; 32 and the rubber sleeve 33 are fixedly connected with the facing brick 2 (the anti-skid block 3 of this embodiment is structurally improved, and can be installed later in the installation. For example: reserve a notch for fixing the lower part of the elastic part 32 on the facing brick 2 And the annular notch for fixing the rubber sleeve is bonded together by glue; it is also possible to pre-embed a small steel skeleton on the facing brick 2 before the floor tile is sintered, and weld the elastic part 32 on the skeleton by slotting in the later stage, and the rubber sleeve Adhesive bonding on the decorative brick 2 is sufficient, because the above-mentioned technology is a conventional technical means in the mechanical field, and the pre-embedded steel skelet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com