Mine borehole radar fine detecting device based on drilling machine pushing and detecting method thereof

A borehole radar and fine detection technology, which is applied in the directions of surveying, earthwork drilling, borehole/well components, etc., can solve the problems of limited detection range, complex structure, small scale of geological targets, etc., to meet the requirements of detection radius, operation Simple, satisfying the effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

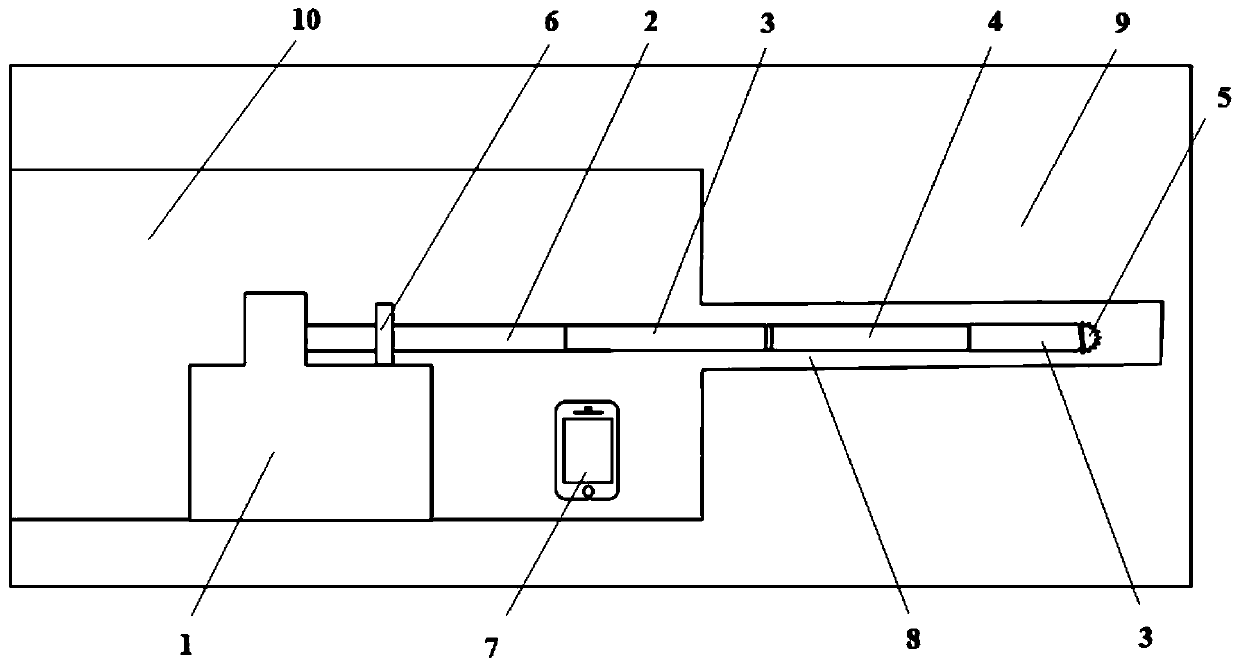

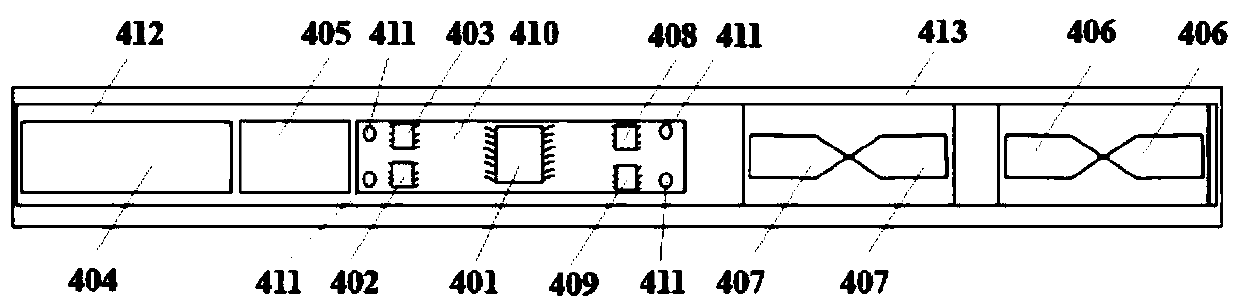

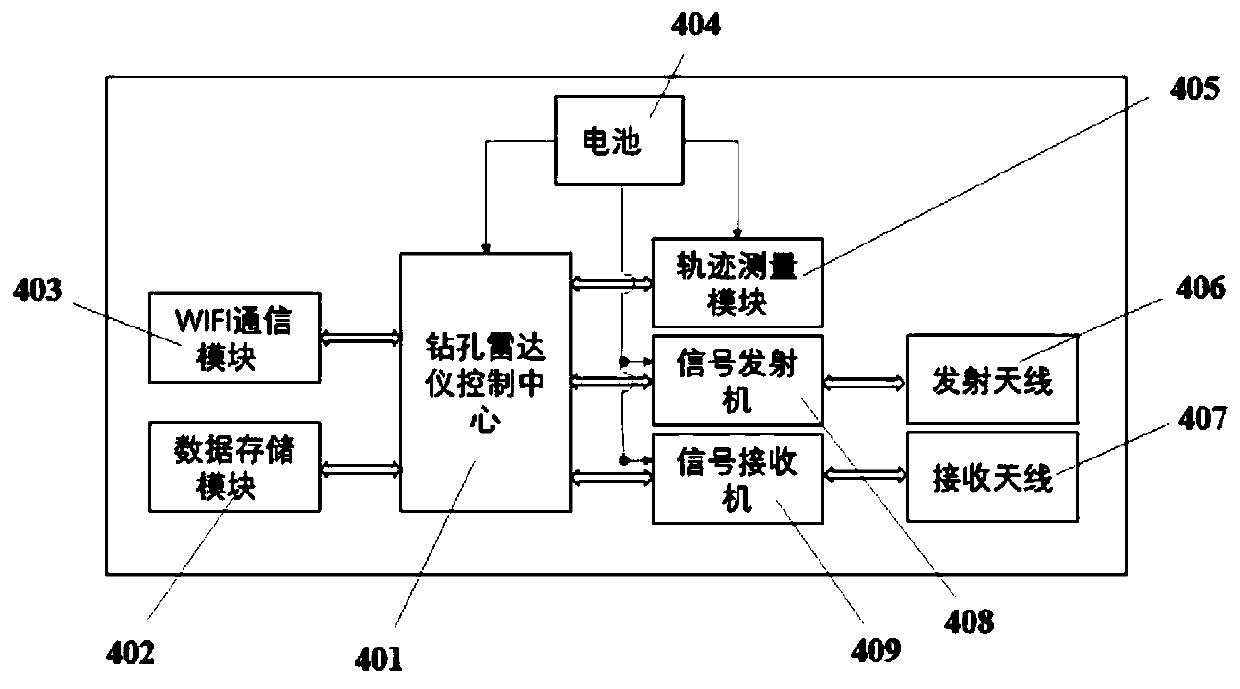

[0058] Such as Figure 1 to Figure 4 As shown, the present embodiment provides a mining drilling radar fine detection device based on drilling rig push, including drilling rig 1, drilling rod 2, non-metallic drilling rod 3, drilling radar instrument 4, non-metallic drilling rod connected in sequence 3 and drill bit 5; also includes a hole depth recorder 6 and an explosion-proof mobile phone 7, the hole depth recorder 6 is installed on the drilling rig 1 to record the depth of the drilling radar instrument 6 in the borehole, and the explosion-proof mobile phone 7 communicates with the hole depth through WIFI The recorder 6 communicates with the borehole radar 4 to synchronize time, issue parameter commands and transmit data for the borehole recorder 6 and the borehole radar 4; the borehole radar 4 includes a borehole radar control center module 401, a drill Hole radar data storage module 402, borehole radar WIFI communication module 403, borehole radar battery 404, track measur...

Embodiment 2

[0071] This embodiment provides a detection method based on the mine drilling radar fine detection device pushed by the drilling rig of embodiment 1, it is characterized in that, the detection method comprises the following steps:

[0072] Step 1: Install the hole depth recorder on the drilling rig;

[0073] Step 2: After connecting the non-metallic drill pipe to the drill bit, connect the drilling radar instrument to the non-metallic drill pipe;

[0074] Step 3: Turn on the power control switch on the drilling radar instrument and the hole depth recorder, and start the drilling radar instrument and the hole depth recorder;

[0075] Step 4: Use the explosion-proof mobile phone to connect with the drilling radar and the hole depth recorder through WIFI respectively, set their parameters and time synchronization respectively, and issue the command for the drilling radar and the hole depth recorder to start working;

[0076] Step 5: Add a non-metallic drill pipe to the back end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com