Ultra-high-pressure 200 MW low-pressure cylinder zero-output flexible transformed steam turbine

A low-pressure cylinder and steam turbine technology, applied in steam engine installations, steam applications, mechanical equipment, etc., can solve problems such as dynamic stress risk, blast risk, water erosion risk, etc., to ensure cooling effect, avoid excessive water spray, and reduce blades The effect of water erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

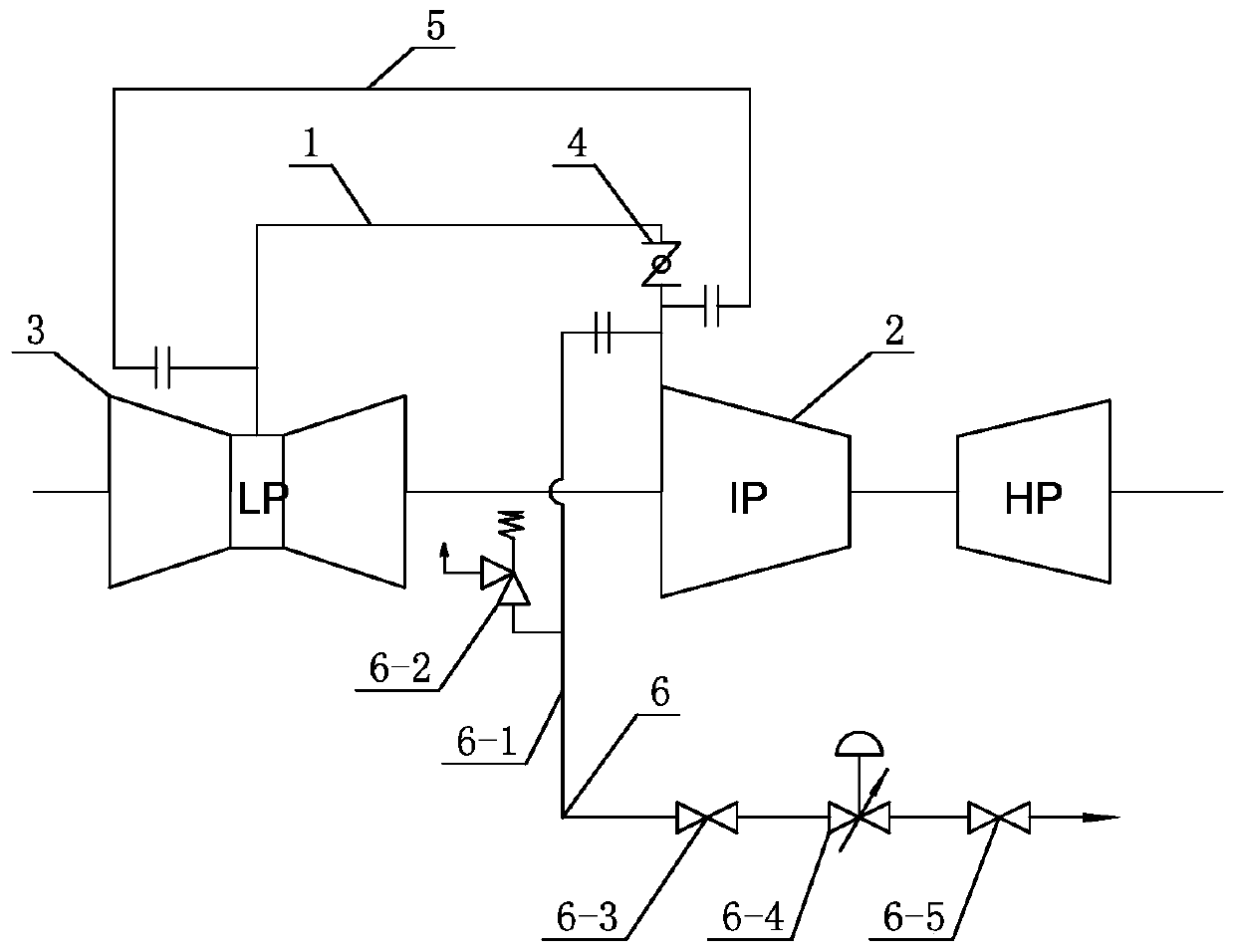

[0024] Specific implementation mode one: combine figure 1 Describe this embodiment. In this embodiment, the ultra-high pressure 200MW low-pressure cylinder zero-efficiency flexible retrofit steam turbine includes a high-pressure cylinder, a medium-pressure cylinder 2, a low-pressure cylinder 3, a low-pressure cooling steam system 5, and a heating and extraction system 6 and the low-pressure cylinder water spray system 7, a medium-low pressure connecting pipe 1 is set between the medium-pressure cylinder 2 and the low-pressure cylinder 3, and the medium-low pressure connecting pipe 1 is provided with a heating extraction interface and a cooling steam outlet of the low-pressure cylinder along the steam outlet direction. The steam port, the butterfly valve 4 and the cooling steam inlet of the low-pressure cylinder, the steam inlet of the low-pressure cooling steam system 5 are connected to the cooling steam outlet of the low-pressure cylinder, and the steam outlet of the low-press...

specific Embodiment approach 2

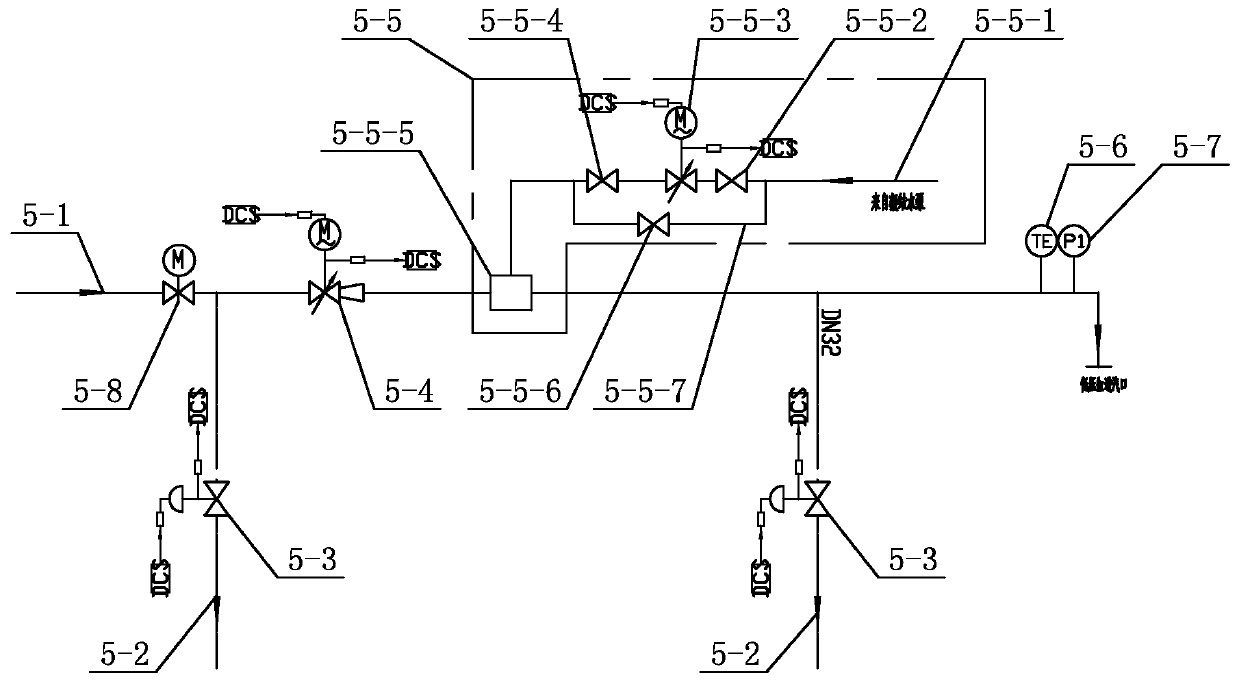

[0028] Specific implementation mode two: combination figure 2 Describe this embodiment. In this embodiment, the low-pressure cooling steam system 5 includes a steam seal pipe 5-1, an electric gate valve 5-8, two drain pipes 5-2, two second regulating valves 5-3, The first electric flow regulating valve 5-4, the temperature regulating station 5-5, the thermocouple 5-6 and the pressure gauge 5-7;

[0029] The steam inlet end of the steam seal pipe 5-1 is connected to the cooling steam outlet of the low-pressure cylinder, and the steam outlet end of the steam seal pipe 5-1 is connected to the cooling steam inlet of the low-pressure cylinder. The flow direction of the steam is provided with an electric gate valve 5-8, a water outlet of the first drain pipe, a first electric flow regulating valve 5-4, a temperature regulating station 5-5, a water outlet of the second drain pipe, a thermocouple 5-6 and Pressure gauge 5-7, one of the drain pipes 5-2 is connected to the outlet of th...

specific Embodiment approach 3

[0033] Specific implementation mode three: combination figure 1 Describe this embodiment. In this embodiment, the heating extraction system 6 includes an extraction pipeline 6-1, a safety valve 6-2, a check valve 6-3, a regulating valve 6-4 and a shut-off valve 6-5. , the steam inlet end of the steam extraction pipeline 6-1 is connected to the heating extraction steam interface, and a safety valve 6-2, a check valve 6-3, and a regulating valve are sequentially arranged on the steam extraction pipeline 6-1 along the steam outlet direction 6-4 and shut-off valve 6-5.

[0034] Other compositions and connection methods are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com