Kalina cycle waste heat power generation system coupled with lithium-bromide absorption-type refrigerating

A Karina cycle, absorption refrigeration technology, applied in refrigerators, adsorption machines, refrigeration and liquefaction, etc., to achieve the realization of operating conditions, improve waste heat recovery efficiency and power generation efficiency, and facilitate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

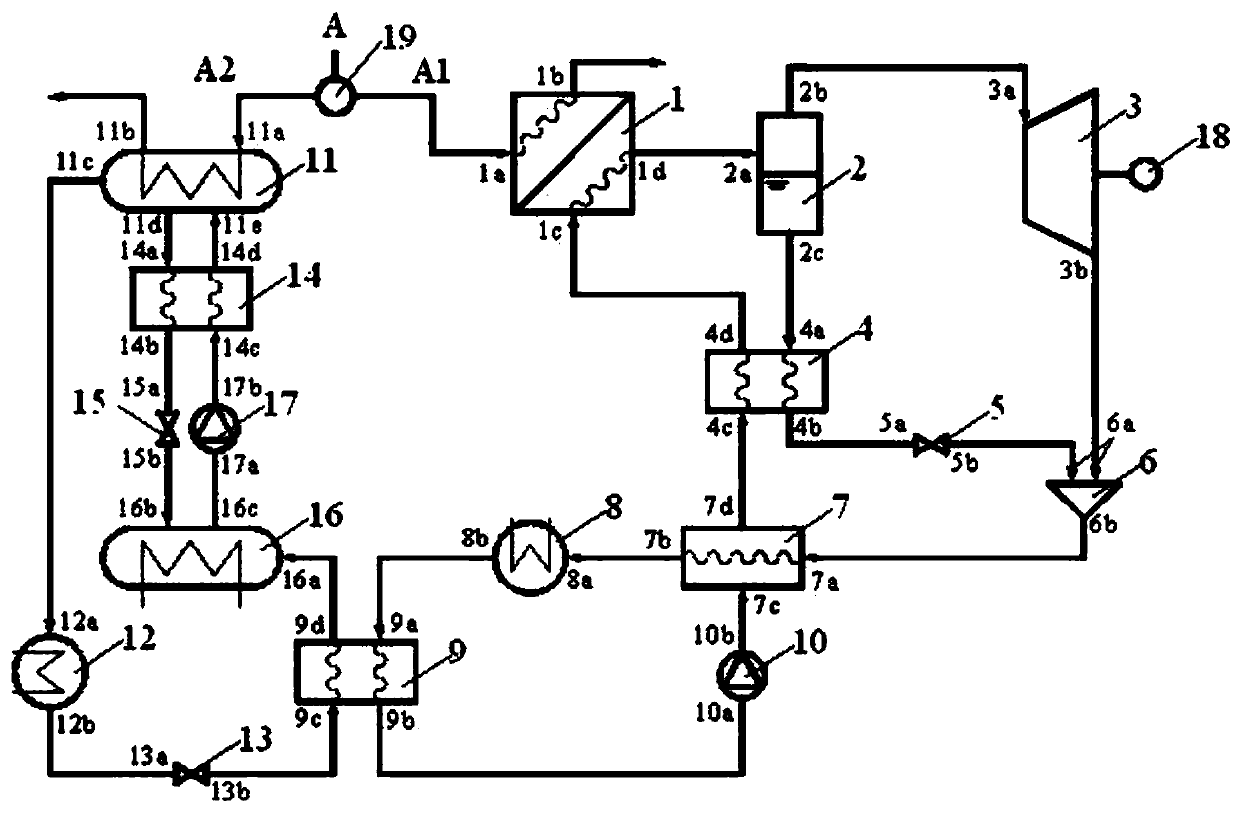

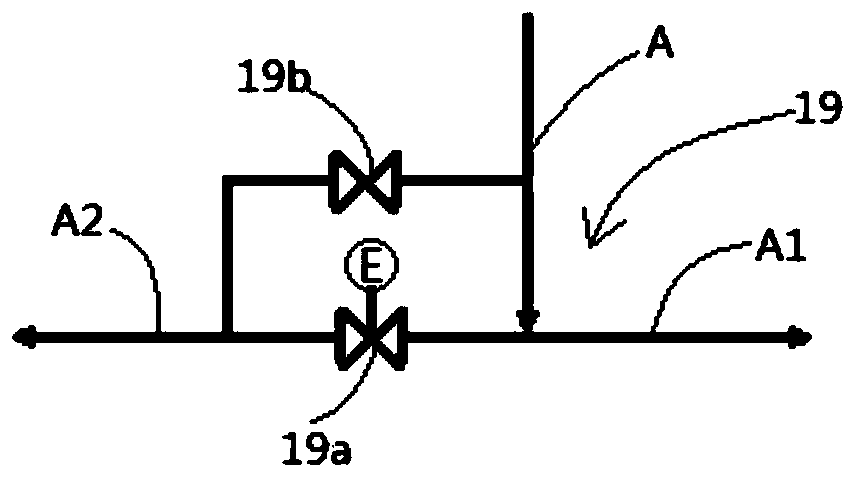

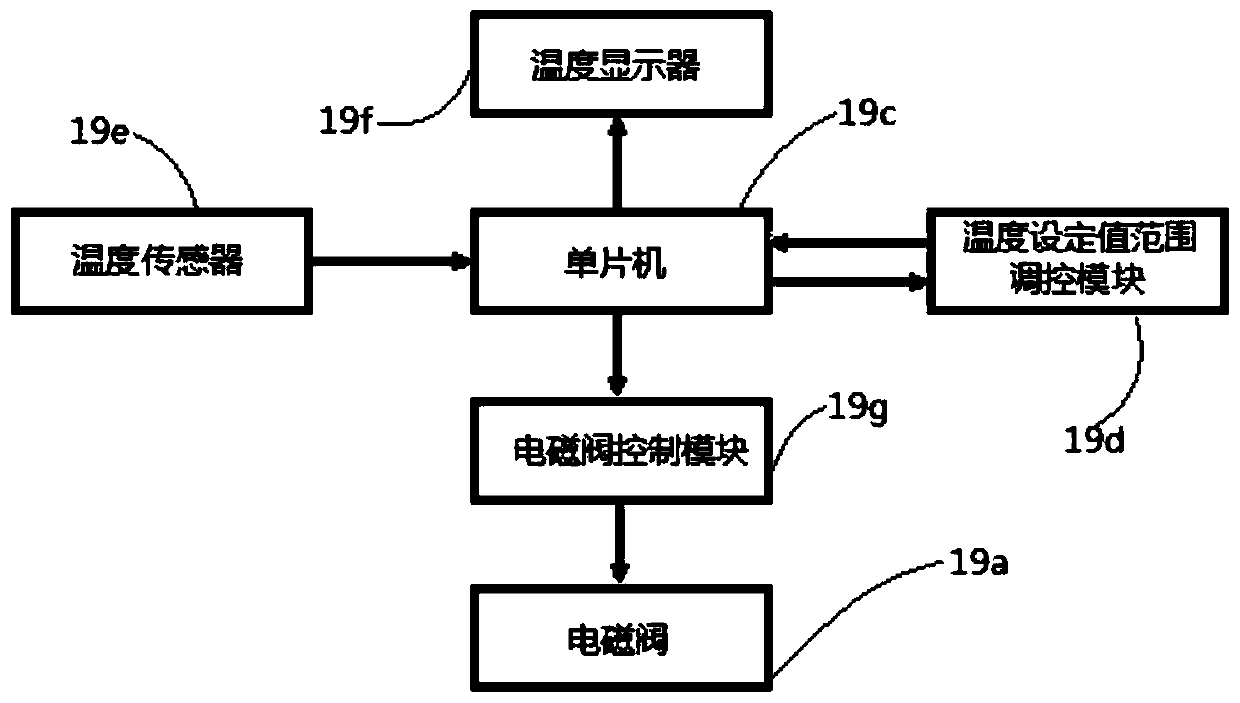

[0028] The present invention will be described in detail below in conjunction with accompanying drawing, as figure 1 As shown: the present invention provides a Karina cycle waste heat power generation system coupled with lithium bromide absorption refrigeration, including a Karina cycle power generation system, a lithium bromide absorption refrigeration system and a second evaporator 9 .

[0029]The Kalina cycle power generation system includes a first evaporator 1, a gas-liquid separator 2, a turbine 3, a generator 18 driven by the turbine, a first heat exchanger 4, a mixer 6, and a second heat exchanger 7 and the first condenser 8; the first evaporator is provided with the first evaporator high temperature side inlet 1a, the first evaporator high temperature side outlet 1b, the first evaporator low temperature side inlet 1c and the first evaporator low temperature side Outlet 1d; said gas-liquid separator is provided with gas-liquid separator gas-liquid mixing inlet 2a, gas-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com