Stretched film and method for producing stretched film

A manufacturing method and film technology, applied in chemical instruments and methods, flat products, polarizing elements, etc., can solve problems such as increased shrinkage, and achieve the effects of small dimensional change rate, excellent bonding strength, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

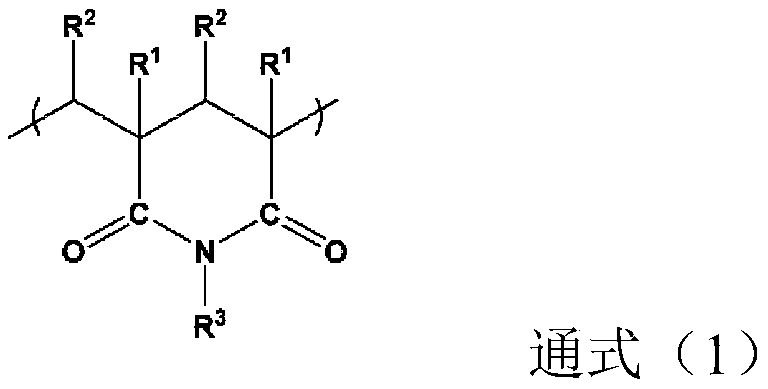

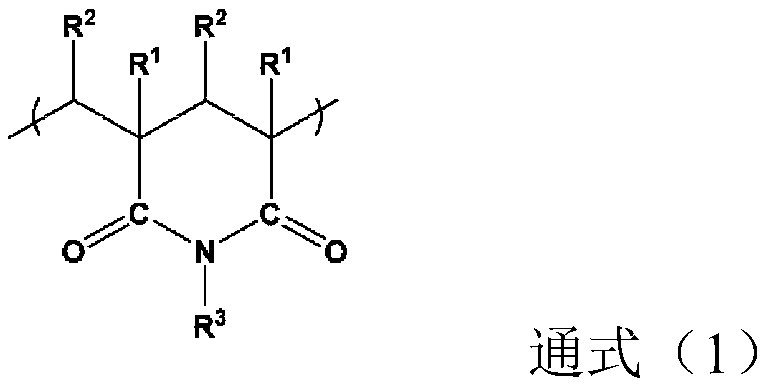

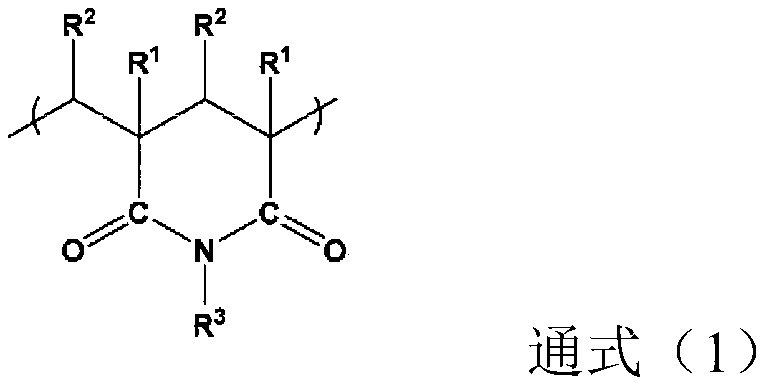

Method used

Image

Examples

Embodiment 1

[0203] A mixture containing 10% by weight of the acrylic resin (A1) and acrylic rubber pellets (B1) produced in the above-mentioned acrylic resin production example was used with an intermeshing type co-rotating twin-screw extruder (L / D =30) for kneading. The resin mixture was supplied from a hopper at 2 kg / hour, the set temperature of each temperature control zone of the extruder was set to 260° C., and the screw rotation speed was set to 100 rpm. The resin that came out as strands from the die provided at the exit of the extruder was cooled in a water tank, and then pelletized with a pelletizer to obtain an acrylic resin composition (C1).

[0204] After drying the obtained acrylic resin composition (C1) at 100° C. for 5 hours, an intermeshing type co-rotating twin-screw extruder (L / D=30) with a diameter of 15 mm equipped with a T-die at the exit of the extruder was used. Make a film. The acrylic resin composition (C1) was supplied from a hopper at 2 kg / hour, the set temper...

Embodiment 2

[0217] A biaxially stretched film was obtained in the same manner as in Example 1, except that the original reverse film (D1) was simultaneously biaxially stretched at a temperature 26° C. higher than the glass transition temperature. The shrinkage rate, peel strength, and number of times of MIT reciprocating bending were measured according to the above-mentioned method. The results are shown in Table 1. Furthermore, the internal haze was measured and found to be 0.18.

Embodiment 3

[0219] A biaxially stretched film was obtained in the same manner as in Example 1, except that the original reverse film (D1) was simultaneously biaxially stretched at a temperature 31° C. higher than the glass transition temperature. The shrinkage rate, peel strength, and number of times of MIT reciprocating bending were measured according to the above-mentioned methods. The results are shown in Table 1. Furthermore, the internal haze was measured and found to be 0.19.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com