Ultrasonic transducer, acoustic impedance matching layer and preparation method of acoustic impedance matching layer

A technology of ultrasonic transducers and matching layers, which is applied in the direction of sound-emitting devices, instruments, and fluids using vibrations, etc., can solve the problems of increased processing technology difficulty, energy loss, and small thickness of matching layers, etc., to achieve improved axial resolution and information richness, improve transmission efficiency, and reduce the effect of pulse width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

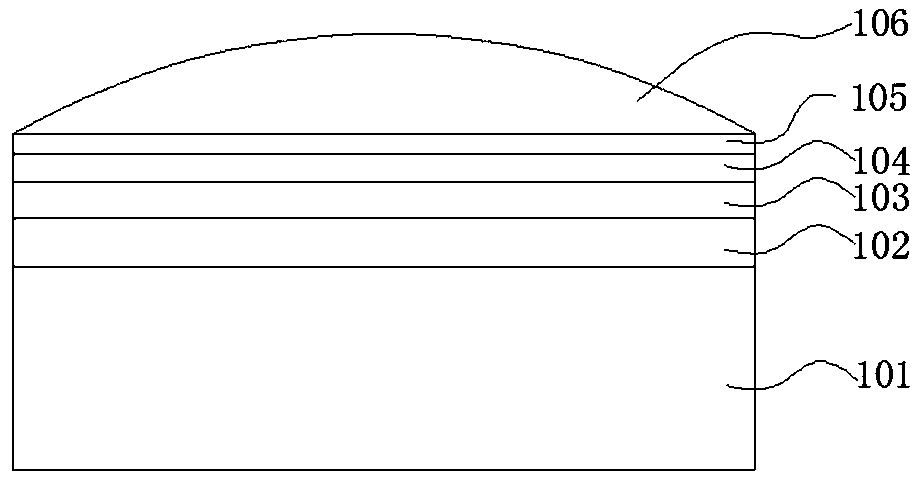

[0043]

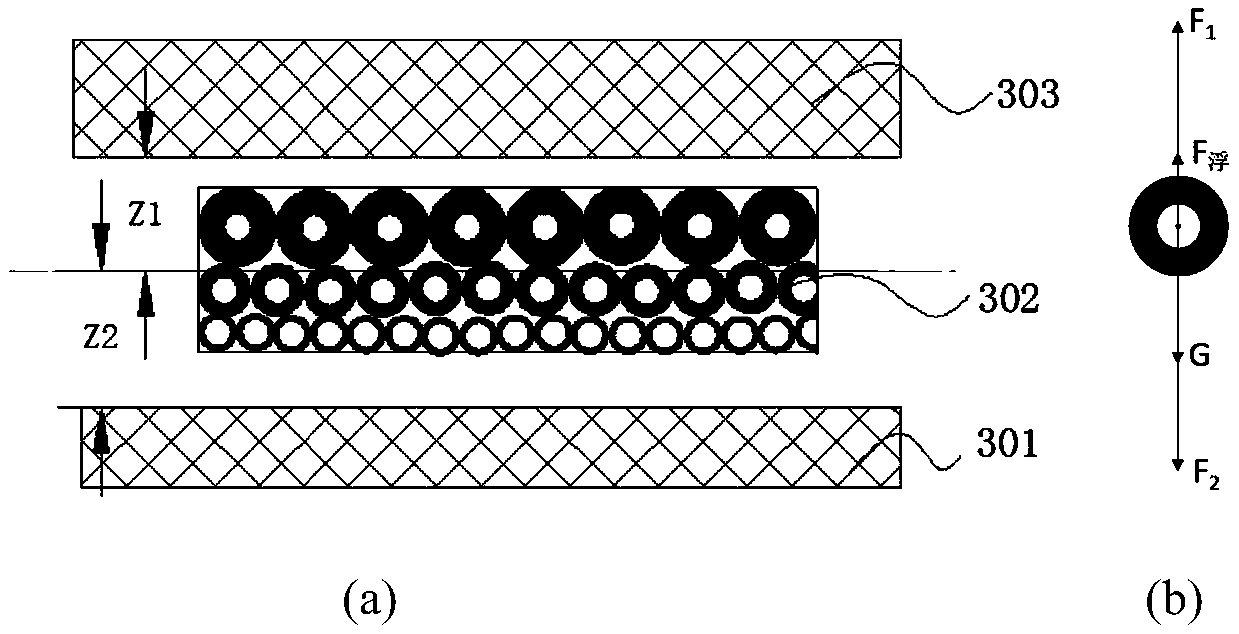

[0044] The present invention also provides a method for preparing an acoustic impedance matching layer, comprising the following steps: screening the magnetic particles, and coating the surface of the magnetic particles with a low-density material, so that the particle size of the magnetic particles or the thickness of the low-density material is gradient Distribution: Disperse the obtained magnetic particles coated with low-density materials in a container filled with liquid adhesive, apply a magnetic field to the container from top to bottom, and keep it for a certain period of time, so that the magnetic particles in the container are stable Distributed in the liquid adhesive; solidify the material in the container, take out the cured material, and grind both sides to obtain the acoustic impedance matching layer.

[0045] The screening of magnetic particles can screen out magnetic particles with the same particle size, and then coat the particles by physical or che...

Embodiment 1

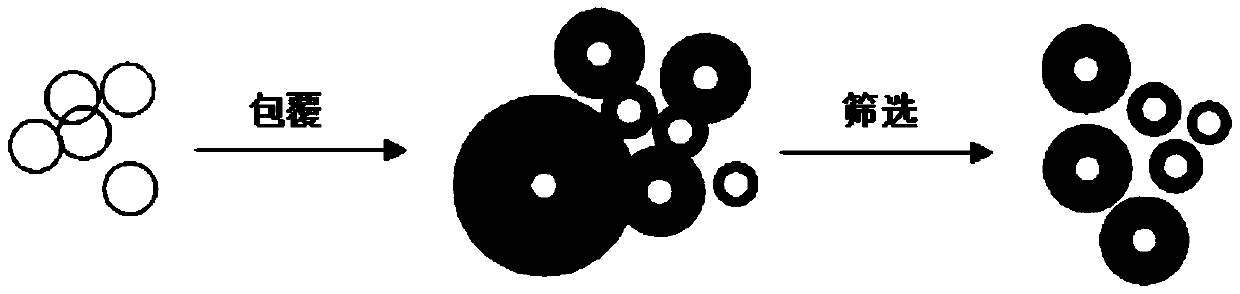

[0051] The method of screening first and then coating is used to prepare the magnetic filling particles.

[0052] like figure 2 As shown, the iron particles with a particle size of (10-15) μm are screened out through the upper and lower sieves, and the density is about 7g / cm 3 , The acoustic impedance is about 33MRayl. A layer of silicone rubber material is coated on its surface by in-situ polymerization method, and the density of the selected silicone rubber material is about 1g / cm 3 , the acoustic impedance is about 1MRayl. By controlling the reaction temperature and prolonging the reaction time, a layer of (0-120) μm thick coating layer is coated on the surface of iron micro-particles, and the density of the obtained composite particles varies in the range of about (1.1-7) g / cm 3 , through screening to obtain mixed particles with a gradient distribution of particle size (or density).

[0053] Use epoxy resin with low viscosity as the adhesive, such as EPOTEK 301, DER 3...

Embodiment 2

[0057] The method of screening first and then coating is used to prepare the magnetic filling particles.

[0058] like Figure 5 As shown, the magnetic particles with particle size gradient distribution are screened out by sieving or cyclone separation, and then the conditions are precisely controlled, and the particle surface is coated in equal amounts by physical or chemical methods such as sputtering, vapor deposition, in-situ polymerization, and rotary evaporation. A layer of low-density material is covered, because the particle size of the uncoated particles presents a gradient distribution, so the density of the coated composite material also presents a gradient distribution, that is, the stress presents a gradient distribution. Then, the matching layer material 601 with a gradient distribution of acoustic impedance is obtained by designing with the same principle as in Embodiment 1, as Image 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com